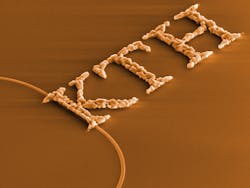

High-quality copper oxide microcrystals are synthesized for quantum photonics

Cuprous oxide (Cu2O) is a promising material for quantum photonics and optoelectronics, due to its ability to simulate highly excited Rydberg atomic states via the formation of solid-state excitons within the material; such excitations can be interfaced with photonic integrated circuits for on-chip generation and manipulation of light at the single-photon level. Now, a team of researchers from KTH Royal Institute of Technology (Stockholm, Sweden), Graz University of Technology (Graz, Austria), and CNRS, École Polytechnique (Palaiseau, France) has found a way to synthesize high-quality Cu2O microcrystals.

Making the crystals involves heating a copper thin film to high temperatures in vacuum conditions. In the study, the researchers took this method and identified the growth parameters needed to fabricate Cu2O microcrystals with excellent optical material quality and low levels of point defects and impurities. The process is compatible with standard silicon fabrication techniques and allows the possibility for photonic circuit integration. In a photoluminescence experiment, emission peaks corresponding to Rydberg excitons up to n = 6 were seen in the fabricated microcrystals.

“The majority of quantum optics experiments with this material have been performed with geological samples found in mines—for instance, the Tsumeb mine in Namibia,” says Stephan Steinhauer, a researcher at KTH. “Our synthesis method is associated with very low-cost fabrication, suitable for mass production, and does not require gases or chemicals that are toxic or harmful for the environment.” He notes that the properties of Cu2O can lead to new schemes for quantum information processing with light in the solid state, which are difficult to realize with other materials. Reference: S. Steinhauer et al., Commun. Mater. (2020); https://doi.org/10.1038/s43246-020-0013-6.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.