Optical components maker Inrad Optics (Northvale, NJ) has received a Phase I Small Business Innovation Research (SBIR) award from the U.S. Department of Energy (DOE) to support development of neutron imaging technology.

The detection and imaging of neutrons is a critical capability for nuclear nonproliferation applications that require identification of plutonium and uranium. There is growing interest in fieldable, pixelated fast neutron detectors, which permit gamma discrimination. Additional applications exist in research, nuclear power, and nuclear security.

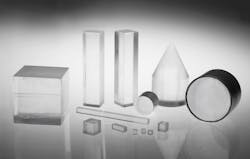

Scintinel stilbene, an organic scintillator produced by Inrad Optics, exhibits good performance for neutron detection and has been used by researchers in academia, industry, and national laboratories. SBIR funding from the DOE will facilitate new applications in neutron imaging through the development of pixelated stilbene arrays coupled to silicon photomultipliers (SiPMs).

This work is supported by the U.S. Department of Energy, Office of Science, National Nuclear Security Administration, under award number DE-SC0020743. This support does not constitute an express or implied endorsement on the part of the Government.

For more information, please visit inradoptics.com.