Achromatic lenses are typically composed of multiple elements cemented together. Each element is made from a different material, and the difference in the refractive indices of the materials allows the achromat to correct for chromatic focal shift. This results in at least two different wavelengths coming to a common point of focus.

However, a new type of lens is challenging the notion that multiple materials must be used for chromatic aberration correction. Achromatic singlet lenses use a unique aspheric geometry to minimize chromatic focal shift and are made from a single substrate, breaking the traditional rules of achromatic lens design (see Fig. 1). They offer several advantages over traditional cemented achromats, including correction over a wider wavelength range, more thermal stability due to no difference in coefficient of thermal expansion between different substrates, and increased compatibility with high-power lasers because the design is cement-free.

Creating a custom ray-tracing algorithm

Existing optical-design software such as Zemax OpticStudio, Synopsys CODE V, and others provide solutions for designing and optimizing aspheric optical surfaces. However, the surface parameters that they vary are typically limited by one of the polynomial equations often used to characterize aspheric surfaces, such as:

Where:

Z = surface sag measured parallel to the optical axis

s = radial distance from the optical axis

C = curvature, or the inverse of radius

k = conic constant

A4, A6, A8...= 4th, 6th, 8th… order aspheric coefficients

These equations are useful for designing certain types of aspheres, but they inherently limit the solution space for aspheric designs. New design solutions can be found when not limited to a set number of aspheric coefficients. In fact, every point on the surface can vary, unbounded by the arbitrary constraints of conventional polynomial representation. A new ray-tracing algorithm was created in Matlab to vary the discretized local surface slope across an optical component beyond the shapes possible in polynomial representation while still being realistically manufacturable.1

However, this custom code certainly has some limitations. Opening up the solution space makes it significantly more complex to accurately analyze multiple elements, higher-level aberrations, field performance, and manufacturing tolerances. Once a promising solution was created in Matlab, it was analyzed in Zemax OpticStudio for more thorough evaluation before moving to prototyping.

Nominal performance

The custom ray-tracing code produced an achromatic singlet design whose nominal performance indicated a number of benefits over conventional, multiple-material achromatic lenses. The two surfaces of the achromatic singlet somewhat mirror each other and balance out the chromatic dispersion experienced at each individual surface. One surface has a discontinuity on axis with an infinitesimally small radius of curvature. This feature will have some amount of curvature when actually manufactured, introducing some stray light. However, this effect is negligible for the majority of applications because the discontinuity area is a very small portion of the full aperture area.

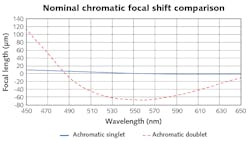

The achromatic singlet showed significantly reduced chromatic focal shift over a broad wavelength range. For a wavelength range of 450 to 650 nm, 10 µm of nominal chromatic focal shift was observed for a 100 mm focal length, 0.097 numerical aperture (NA) single-material achromat (see Fig. 2).1 This is an improvement of a factor of 20 when compared to the 200 µm nominal chromatic focal shift of a comparable 100 mm focal length, 0.013 NA achromatic doublet. Both lenses had a 25 mm clear aperture.Manufacturing achromatic singlets

The discontinuity and the rest of the unique geometry of achromatic singlets provides some manufacturing challenges compared to other optical components. Diamond turning offered a solution to fabricating these lenses. Matlab converted the surface parameters into a format that could be read by a Moore Nanotech 250 UPL diamond-turning lathe. Talysurf profilometry data and the kinematic location of datum structures allowed for some iteration to align the front and back surfaces. The flat datum structures greatly simplify alignment.1 The lenses were diamond-turned from Zeonex E48R substrates (see Fig. 3).Real-world performance

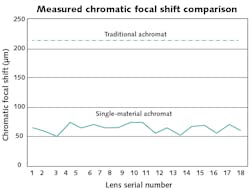

The main performance metric the lenses were evaluated on was chromatic focal shift. The nominal performance of the achromatic singlet was promising, but would the actual lenses still be able to outperform traditional achromats? Eighteen achromatic singlets were manufactured and evaluated by using an Optikos modulation transfer function (MTF) test bench at a resolution of 40 lp/mm and five different 10 nm bandpass filters to measure the position of best focus at different wavelengths. The lenses were measured for wavelengths covering 450 to 650 nm. While MTF is typically used to evaluate imaging lenses and not achromats, MTF is useful for locating the best focal point by finding the smallest spot size.

The filters had center wavelengths of 450, 500, 550, 600, and 650 nm. Light from a halogen bulb was passed through the optical filters onto a pinhole, and light from the pinhole was collimated and passed through the lens under test. The lens’ point-spread function was captured by a microscope relay imager at the focal plane. This data was then used to determine the lens’ MTF. A z-axis stage translated the imager up and down the optical axis to obtain a through-focus MTF measurement. The spot where MTF was best was used to determine the position of best focus for each wavelength, revealing the chromatic focal shift.

The measured chromatic focal shift of the 18 achromatic singlet samples varied from 49 to 75 µm (see Fig. 4).1 This outperformed the conventional achromatic doublet, which had a chromatic focal shift of around 210 µm when tested using the same method, by a factor of three. While manufacturing tolerances resulted in performance less than that of the nominal design, the achromatic singlets still significantly outperformed the doublet.The experimental results demonstrate that broadband achromatic performance can be achieved using a single optical material, breaking the assumed rules of achromatic lens design. Cemented doublet or triplet achromats are extremely common in optical systems, and some of them may begin to be replaced by achromatic singlets in the coming years. The unique geometry of achromatic singlets provides powerful chromatic correction without the mismatch in thermal properties and reduced laser-induced damage threshold (LIDT) associated with cementing multiple materials together. Achromatic singlets are promising for broadband focusing applications, particularly when using high powers or in ultraviolet systems where optical cement is not desired.

REFERENCE

1. J. Bagwell, C. Hebert, and N. Carlie, Proc. SPIE, 11261, 1126110 (Feb. 21, 2020); https://doi.org/10.1117/12.2541451.

Cory Boone | Technical Marketing Manager, Edmund Optics

Cory Boone is the Technical Marketing Manager at Edmund Optics’ Barrington, NJ, USA office. He is responsible for managing the creation of technical marketing content, including application notes, published articles, web copy, email campaigns, video scripts, trade show materials, case studies, and other marketing literature. He plans the company’s technical content strategy and acts as the technical voice of the marketing department. Cory is also active in educational outreach and spreading general awareness of the optics industry. He received a B.S. in Optical Sciences and Engineering along with minors in Math and Material Science Engineering from the University of Arizona.