Augmented and mixed reality (AR/MR) technology is moving rapidly from niche applications toward more-widespread consumer use in immersive gaming, healthcare, safety, athletics, and business. With digital data displayed alongside reality via smartphones or wearable eyewear, AR/MR technology uses photonics to display a layer of useful data over our view of the real world. Today’s AR wearables enable, for example, a vehicle designer to envision a new headlight style, or a warehouse employee to locate target inventory.

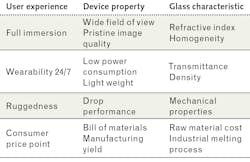

The ultimate trophy, however, is to reach widespread commercial adoption, a world in which AR glasses are comfortable, affordable, natural, and easy to use, and as ubiquitous as smartphones. In addition, they must be streamlined and attractive enough for everyday use. Many first-generation and even second-generation AR models are available today, yet none of them check all these boxes (see table).According to market intelligence firm International Data Corporation (Framingham, MA), worldwide spending on augmented and virtual reality (AR/VR) will accelerate out of the pandemic, growing from just over $12.0 billion in 2020 to $72.8 billion in 2024, with AR/VR five-year spending at a compound annual growth rate (CAGR) of 54.0%.1 In light of this potential, hundreds of companies have invested billions of dollars in AR, VR, and MR development in the past few years to address the challenges. To reach a global consumer market, every optical component in AR must push the boundaries of technology to be manufacturable at mass volumes and lower the ultimate cost to the consumer. Simultaneously, a successful AR solution also needs to achieve a high-quality image, a large field of view (FOV), and a full-immersion experience in a compact form factor without added weight or bulk.

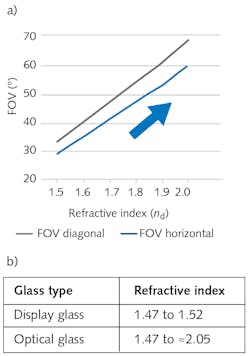

The need for a wide FOV combined with a projection surface only an inch or so from the wearer’s eye presents major constraints to the AR hardware that guides the light from the projector to the eye. The original Google Glass headset, the first consumer AR device to reach the market, had a horizontal FOV of only 12.5°. The fixed foveated region of human-sustained eye gaze measures 40° to 50° wide, which defines current state-of-the-art horizontal FOV in commercial MR devices like the Microsoft HoloLens 2 (43°). Human binocular vision encompasses a FOV of 120°, so many next-generation consumer AR systems are driving to wider FOVs for a more compelling, fully immersive experience (see Fig. 1).

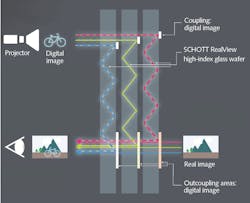

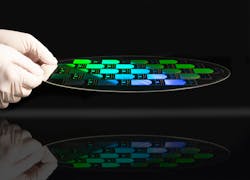

Google Glass used a flat optical combiner composed of a mirror and polarizing beamsplitter—a traditional optical concept. Various other optical-combiner designs may involve the use of mirrors, prisms, curved combiners, or freeform optics. These optical combiners lend themselves to rather bulky and less wearable designs; conservation of etendue simply doesn’t allow for both miniaturization and wider FOV.The high-index glasses ideal for AR cannot be manufactured using the established manufacturing processes used for display glasses. Optical glass serving as light guides must be processed into wafers with extremely tight tolerances. Thickness uniformity and root-mean-squared (RMS) roughness of the surface actually have to be an order of magnitude better than those of typical display substrates—in other words, completely flat. In response, glass producer SCHOTT AG (Mainz, Germany) introduced the RealView line of high-index glass wafers, continuously extended since its 2018 launch. Specifications for the total thickness variation of the glass wafers are <1 µm, and <1 nm for surface roughness. This enables an undisturbed light path and a minimal amount of scattering for unconstrained image projection.

Different waveguide approaches

The light management structure on the surface of a waveguide typically involves a diffractive optical element (DOE) that injects the light over a small area into the waveguide, distributes it to a large exit pupil, and extracts it to the eye.3 Diffractive waveguides are considered the most mature AR combiner technology, used in the Microsoft HoloLens, Magic Leap One, and Vuzix M4000. Alternatively, a holographic optical element (HOE) can fulfill the same waveguide function as a DOE. DOEs are nanophotonic structures manufactured using either subtractive methods, such as reactive ion etching (RIE), or additive processes, such as nanoimprint lithography (NIL), the latter of which requires a resin with a refractive index matching that of the glass.

Another approach is the reflective waveguide. A novel reflective waveguide design developed by Israeli AR company Lumus does not require nanophotonics. Instead, a 1D or 2D array of semitransparent mirrors along the optical path directs the light towards the user’s eyes. Lumus’ reflective waveguide design achieves exceptional power efficiency, color uniformity, and low forward-light leakage for a glare-free AR experience. While tolerances of the waveguide itself are comparable to that of DOE technology, reflective waveguide technology involves a different manufacturing process and requires even higher glass homogeneity.

Bringing consumer AR technology to maturity requires an entire new ecosystem to take shape, particularly around demanding manufacturing requirements. SCHOTT’s approach is to partner with leading players in their fields of expertise. One important partnership in the NIL ecosystem has been established with optics designer and manufacturer WaveOptics (Abingdon, England), nanotech coating developer Inkron (Espoo, Finland), and process equipment supplier EV Group (St. Florian, Austria). WaveOptics has launched diffractive waveguides with different optical architectures using between one and three waveguide layers. While their three-layer flagship solution ODIN offers a FOV as high as 60°, their one-layer ultrathin KATANA design is lightweight and features low power consumption.4 Single-layer designs require less-rigorous manufacturing tolerances and a simplified bill of materials. A viable approach to next-generation waveguides was demonstrated on n = 1.9 RealView 300-mm wafers using the NIL capabilities of EVG and Inkron’s n = 1.9 resin (see Fig. 4).Alternately, a benefit of RIE over NIL as a manufacturing approach to AR glasses is that a polymer resin layer is not needed, thus removing the limitation on the refractive index. Patterns or gratings can be etched into the high index coatings or glass itself, which could unlock the potential of glass with indices greater than 2.0.5 Although RIE is more costly than NIL at first blush, comparative cost improves as production quantities increase. No commercial AR devices made using RIE capabilities have yet been launched, but high-volume RIE manufacturing is coming closer to fruition using 300 mm wafers.

Whichever waveguide approach is used, the choice of substrate is a critical part of how AR glasses will be manufactured. Furthermore, bringing wafer manufacturing to an unprecedented level of precision and reproducibility with tightest tolerances is critical in helping establish a new supply chain, facilitating faster high-quality pilot runs and enabling mass volume manufacturing at attractive cost.

Optical glass development

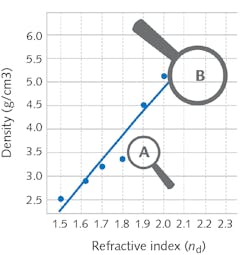

Typically, new product generations with advanced device properties present challenging requirements for the glass substrates. If high refractive index is the enabler of wide FOV, strong electromagnetic (EM) interaction is required at the atomic level to facilitate photons passing through the atomic structure of the material. To achieve strong EM bonds, glass scientists can infuse high amounts of heavy ions such as titanium, lanthanum, or bismuth into the glass matrix, or they can design glass with densely packed atoms, However, heavy atoms and dense packing comes at a price: the specific weight. A statistical analysis of optical glasses currently available from major global suppliers reveals that higher refractive index comes with a density penalty. Also, glasses above n = 1.85 are, statistically speaking, “exotic.” Thus, the wider the FOV, the more weight consumers have to wear on their nose. However, for a given refractive index, we can design glasses with a certain spread of density (see Fig. 5).“Today’s waveguides constitute a significant portion of the target weight of a consumer AR glass,” says Bianca Schreder, principal scientist with SCHOTT’s AR material development group. “Customers are thrilled at the prospect of drastically reducing weight using innovative low-density glass.”

“We are excited to study innovative high-index materials even at the price of higher material density if it helps implement our roadmap to thin, lightweight, quality waveguide displays,” says Ismo Vartiainen, vice president of R&D at design house Dispelix (Espoo, Finland).

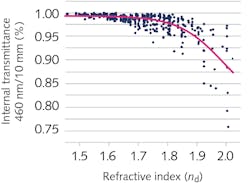

Another challenge to AR glass designers is highly refractive materials with a smaller electronic bandgap, resulting in lower transmission of the blue wavelengths through the waveguide (see Fig. 6). To meet this and other numerous glass challenges, SCHOTT has a development program pioneering novel materials and exploring the tradeoffs between bandgap, density, and index, among other specifications. This program will enable new benchmark AR devices that meet unique specifications, such as combining widest FOV with convenient wearability.“Diffractive waveguide designers for AR understand the tradeoffs between FOV, efficiency, and color uniformity,” says Phil Greenhalgh, chief technology officer of WaveOptics. “But the design envelope gets greater as the refractive index goes up. The coming portfolio of high-index glass will greatly assist us in developing high-performing waveguides at consumer acceptable price-points.”

REFERENCES

1. See http://bit.ly/IDC-Guide.

2. R. Sprengard, Proc. SPIE, 11310, 113102A (Apr. 2020).

3. B. Kress and I. Chatterjee, Nanophotonics, 10, 1 (Oct. 2020).

4. P. Greenhalgh (WaveOptics), SPIE AR/VR/MR Invited Speaker Series (Sep. 2020).

5. Z. Cui, Nanofabrication: Principles, Capabilities and Limits (Springer US; 2017).

Rüdiger Sprengard | Vice President of Augmented Reality, Advanced Optics at SCHOTT AG

Rüdiger Sprengard, Ph.D., is the Vice President of Augmented Reality, Advanced Optics at SCHOTT AG (Mainz, Germany).