Aluminum oxide film soaked in hot water becomes broadband antireflection coating

Types of broadband antireflection (AR) optical coatings include multilayer thin-film, glancing angle deposition (GLAD, which produces somewhat-random subwavelength nanostructures), and patterned subwavelength nanostructures (the last two of these are examples of gradient-index, or GRIN, coatings). Most broadband AR coatings suffer from performance that depends on incidence angle, and also are subject to the well-known tradeoff between overall reflectance and bandwidth. Another type of AR coating can be fabricated by taking an aluminum oxide (Al2O3) coating deposited by atomic-layer deposition (ALD), placing it in hot water, and waiting for the resulting chemical instabilities to modify the coating: the hot water turns the coating into a porous GRIN structure after about a half an hour. The resulting AR coating has good broadband properties and is easy to make. A group of researchers at the Chinese Academy of Sciences (Shanghai, Beijing, and Hangzhou, China), Fudan University (Shanghai, China), and the Center for Excellence in Ultra-intense Laser Science (Shanghai, China) have been working to improve these coatings and make them more resistant to laser damage.

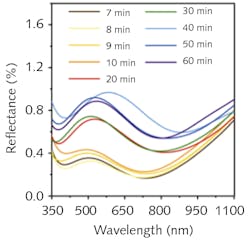

An example experiment starts with Al2O3 coatings with a 44 nm design thickness deposited on substrates of either silicon (for measuring coating thickness) or fused-silica (for measuring all other coating properties) by electron-beam evaporation—a change from the earlier ALD. (An etch is done first to clean the substrate to minimize laser-damage-inducing flaws.) Coatings are soaked in 90°C deionized water for anywhere from 3 to 60 minutes. Root-mean-square (RMS) surface roughness, optical scattering, reflection, absorption, and general surface quality are then measured using various instruments. Next, laser-induced damage testing (LIDT) is done using a 12-ns-pulsed Nd:YAG laser; damage is evaluated using a scanning electron microscope (with a 20 nm chromium film applied to the tested coating).

Reflectance spectra for the coatings show that broadband reflectance reaches a minimum for coatings soaked for 7 minutes. In transmission, a fused silica sample with the AR coating on both sides averages 98.8% over a 350–1100 nm spectral range. The LIDT results showed a damage threshold of 23.9 J/cm2. Reference: C. Yin et al., Opt. Mater. Express (2021); https://doi.org/10.1364/ome.418174.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.