It was April 26, 1954, when The New York Times heralded a bright future for photovoltaic power on its front page: “Vast Power of the Sun is Trapped by Battery Using Sand Ingredient.” Getting there has taken a long time, but now our target is generating half of the world’s electricity from solar energy by 2035, on our way to phasing out fossil fuels for powering the electric grid.

The silicon cells that prompted the headline have come a long way, and most of the 591 GW of photovoltaic power now available to the global grid comes from silicon. Yet, silicon has limits. Theory says its radiative limit—the maximum fraction of incident solar energy that a single p-n junction can convert into electrical energy—is just under 29.5% at normal solar intensity. The best efficiency yet measured in the laboratory is 26.7%, and that requires a heterostructure in the silicon; the best with an ordinary p-n junction is 26.1%, and the fact that the National Renewable Energy Laboratory (Golden, CO) keeps careful track of such details (see Fig. 1) shows just how important they are.

The best values in production now are 23.4%; the practical limit of that technology is about 24.5%.1 Exceeding predicted limits of 26% efficiency in production and 27.5% in laboratory environments will require new materials and technologies such as multijunction solar cells, or tricks such as illuminating cells with sunlight focused to many times the natural intensity. Technologies including III-V semiconductors and tricks such as concentrating sunlight look too expensive to be practical for large-scale power generation, at least in the near-term. The best options are combining a new family of materials called perovskites with new structures to stack two or more materials together to absorb more of the solar spectrum.

The perovskite revolution

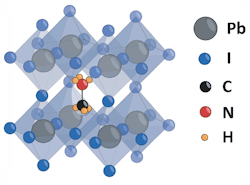

“Perovskites have gotten most of the attention in the last year or so,” says Nancy Haegel, director of the Materials Science Center at NREL. The word perovskite comes from a form of calcium titanate (CaTiO3) first found in the Ural Mountains in Russia and is now widely used for a large family of materials that share the same crystalline structure. The nearly cubic unit cell is called ABX3, with A being an atom or small molecule at the center, B being a transition metal atom at a corner, and X being an atom attached in groups of three at the corners.

In minerals, the A elements typically are electron donors such as calcium or sodium, the B elements are elements such as titanium, and the Xs are oxygen atoms. Other perovskites include semiconductors, and some of these have light absorption and charge transport properties that make them attractive for photovoltaic applications. Of the many tested perovskites, the most promising materials for photovoltaics have small molecules in the center, lead atoms at the corners, and halide atoms attached to the lead. Figure 2 shows one well-studied perovskite semiconductor, with methyl ammonium (CH3NH3) at the center, and lead triiodide groups at each of the corners.Perovskites first entered the photovoltaic race in 2013 with an efficiency of 14%, a number reached by single-junction crystal silicon in 1977. Now, the best single-junction perovskite cells have reached 25.5%—only slightly behind the best single-junction silicon—making perovskites a hotbed of development for new photovoltaic materials.

However, their efficiency is not their only advantage. The ability to deposit perovskites from solution in thin films on other materials, unlike crystalline silicon, reduces the amount of material needed to make a junction. It also allows fabrication of solar cells with multiple junctions—this can get around a physical constraint called the radiative limit, which restricts how efficiently single-junction silicon solar cells can generate electric current. That’s important for NREL and other developers of renewable energy because it could boost how efficiently solar energy can generate electric power on a large scale to reduce fossil fuel carbon emissions.

The radiative limit and tandem cells

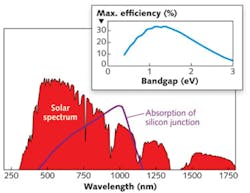

The radiative limit is a consequence of the solar spectrum and how photovoltaic semiconductors produce light. The solar spectrum is that of a blackbody of about 6000 K attenuated by atmospheric absorption (see Fig. 3). Photovoltaic junctions absorb photons with energy higher than the gap between their valence and conduction bands, but only the bandgap energy goes on to produce electric current. The remaining energy is lost as heat, so if a semiconductor with a 1 eV bandgap absorbs a 2 eV photon, 1 eV of energy produces current, but the other 1 eV produces heat.The fraction of the input light energy from a blackbody source (e.g., the sun) that a photovoltaic junction can convert into current depends on the semiconductor’s bandgap energy. The fraction of input light energy converted into usable electric current is highest for a 1.34 eV bandgap—higher than the 1.1 eV bandgap of silicon. The junction transmits photons that lack enough energy to excite a valence electron to the conduction band. If the photon has more energy than needed to excite an electron to the conduction band, the extra energy is lost. The bottom line is that, at best, a single photovoltaic junction can use only a third of the energy it absorbs to generate electric current—the remaining two-thirds of the energy.

The way to beat the radiative limit is by stacking multiple photovoltaic junctions with different bandgaps so light can pass through more than one of them. The junction with the largest bandgap is put on the top of the stack so it absorbs the shortest wavelengths and transmits wavelengths with lower bandgaps, which have longer wavelengths. The next junction layer then absorbs the light with more energy than its bandwidth and transmits the rest. Each junction in the series of tandem layers would skim off photons with energy higher than its bandgap and transmit photons’ lower energies. The stack of tandem junctions would collect a fraction of the light energy it absorbs and use it to generate electric current.

The tandem cells do not skim off all the energy to generate current; much of the energy would be lost, but not as much as for a single junction. In theory, a two-junction tandem cell could convert up to 42% energy of the incident sunlight into electric current, a three-junction tandem call could convert up to 49% into electricity, and an infinite number of junctions could convert up to 68% into electricity.

In practice, absorption and other losses limit efficiency to lower levels. So far, the best conversion efficiency demonstrated for stacking six photovoltaic junctions has been 47.1% using six junction cells based on costly III-V compounds—this was achieved with concentrated sunlight to 143 times its normal power density.2 The NREL table shown in Figure 1 lists the best power-conversion efficiency with six-junction cells at normal solar illumination as-is, at 39.2%. Three- and four-junction cells are available commercially from SolAereo Technologies (Albuquerque, NM) for applications such as powering spacecraft; their power efficiency is 30% to 33%.3

Optimizing materials

Perovskites look good for multijunction cells, and their potential for roll-to-roll manufacturing are attractive because it offers ease of fabrication and low use of materials. Wide-bandgap perovskites can be deposited as top layers both on silicon and on other perovskites with lower bandgaps. Results on silicon have advanced rapidly.4 Recently, Oxford PV (Oxford, UK) reported a record efficiency of 29.52% for a tandem perovskite on silicon solar cells.5 The company has talked about commercial products by the summer of 2022.

Researchers have tested a wide range of perovskites seeking the best composition for large-scale photovoltaic generation of electric power.

“We have a favorite composition that we call the ‘kitchen sink,’ which is a good working mixture,” says Laura Schelhas, a group research manager in chemistry at NREL. Her work involves finding what variations of the compounds work best and how to prioritize their search. Technical issues include efficiency, the long-term material stability needed for solar power plants, and scaling of manufacturing. Schelhas’ group is balancing empirical testing with rational design based on theory. She calls current research and development “a lush ecosystem of universities, national laboratories, and industry all working on these problems. Each has their own perspective and some things are proprietary.” She adds that everyone is looking toward commercialization.

The quest now is for the best perovskite for the job. The 2020 roadmap for photovoltaic technology1 says perovskite solar cells are the only polycrystalline thin-film technology offering both efficiency over 20% and a bandgap of at least 1.7 eV. Matching those wideband materials with narrowband materials such as silicon could produce high-efficiency tandem solar cells for power generation.

But challenges remain. For instance, all efficient photovoltaic perovskites contain lead. Although the amounts are small and solar cells typically remain encapsulated, it’s hard to sell anything incorporating lead as a green technology to the public. Another concern is the durability of perovskites in large solar power stations—a question that could be settled by long-term field trials assessing the stability. Successful field demonstrations of perovskite modules would be an important step toward market entry.

Schelhas is optimistic. “Many of us who work on perovskites think the material has demonstrated enough progress that we can fix any remaining problems. Passivation can often fix interfaces, which are big issues for materials [in general]. Even silicon has its issues.”

The 2020 Roadmap further observes that perovskites “have multiple potential pathways to terawatt-scale energy production.”

Scaling up for the near-term

Although perovskites look like the future for high-volume photovoltaic generation of electric utility power, we can’t wait for that future to arrive to phase out fossil fuels. Other photovoltaics are needed now.

Cadmium telluride (CdTe) is a thin-film material with efficiency of 22.1% in the laboratory (see Fig. 1), already in large-scale production, providing a significant share of utility-scale photovoltaic power. The 2020 Roadmap notes that CdTe power production costs now are competitive with conventional electric generation, with much more R&D needed to reach full potential. Current CdTe has included copper to prove its performance, but efficiencies above 20% have been obtained without copper in the past few years. According to Haegel, ongoing research at NREL and First Solar (Tempe, AZ) suggests doping CdTe with Group 5 elements lead to better efficiency, reliability, and stability. Although cadmium is toxic, encapsulated cells keep the small amounts in CdTe films from reaching the environment.

Another family of thin-film solar cell materials—called CIGS because they contain copper, indium, gallium, sulfur, and selenium—have demonstrated 23.5% efficiency in the laboratory. Various alloys of the semiconductor compound have direct bandgaps ranging from 1 to 2.6 eV, which could make them attractive for use in tandem cells. They already have gained acceptance in Europe and Japan, but are little used in the U.S. The Roadmap calls this group of materials “one of the most versatile in processing, substrate type, and device architecture” for photovoltaics, noting further research could bring efficiency of 25% within reach. CIGS has been studied since the 1970s, and studies of fielded modules show very slow degradation, so their lifetimes might reach half a century.6 That kind of durability is crucial for utility power generation, where solar cells must endure full sunlight for many years.

Crystalline silicon photovoltaic cells have long been the backbone of the global photovoltaic industry, having reached total capacity of 591 GW at the end of 2019, according to the 2020 Roadmap.1 Compounded annual growth during the 2010s was more than 35%. That reflected a drop in price from $100 per watt of capacity in 1976 to about 20 cents per watt in 2019. Efficiency largely plateaued after 1995, with the best laboratory cells rising only slightly to 26.1%, and the mass-produced cells now reaching up to 23.4%. That reflects a largely mature technology, where the most realistic expectations for single-junction cells are expected to be in reducing cost and increasing power available in packaged modules. The best way to increase the efficiency of silicon cells is to use them as the base of tandem cells coated with a thin-film perovskite junction on top, as demonstrated by Oxford PV.

The crystalline photovoltaic cells with the best performance are made of gallium arsenide and other III-V compounds. Those are the photovoltaics used in the most demanding space and military missions, and they score high on the NREL efficiency chart. However, the cost of manufacturing them remains too high for large-volume production, with no easy way of driving it down in the near-term.

Outlook

What makes perovskites the center of the action for large-scale photovoltaics is evident in Figure 1. Their efficiencies are rising faster on the chart than any other emerging technologies, so further research and development is likely to be fruitful. Perovskites also show particular promise for solving the high-priority problem of replacing fossil fuels in generating the vast amount of power our advanced society requires.

Tandem cells using a wide bandgap perovskite junction with crystalline silicon or with a low-bandgap perovskite offers a logical improvement to increase output power at reasonable cost. Other design configurations are also promising. Schelhas cites progress in bifacial photovoltaics, which collect light on their back or bottom as well as on the sun-facing side of a solar farm. Removing the metal layer from the bottom of crystalline solar cells lets them collect light reflected from the grass below the collecting panels. She doesn’t expect it to boost energy collection as much as tandem cells, but it would help, and it could be added to tandem cells if the site was suitable.

Another option is coating windows of glass-walled buildings with photovoltaic films that absorb some light, but not so much that they darken the inside. Silicon is not an option because it absorbs visible light, but perovskites and other thin-film materials could work. Windows won’t get us terawatts of electricity to generate half of the world’s electricity by 2035, Haegel notes, but on a larger utility scale, “you want photovoltaic arrays out to catch as many photons as they can.”

REFERENCES

1. G. M. Wilson et al., J. Phys. D: Appl. Phys., 53, 493001 (2020); doi:10.1088/1361-6463/ab9c6a.

2. M. A. Green et al., Prog. Photovolt., 565–575 (2019); doi:10.1002/pip.3171.

3. See https://bit.ly/3BTxXbj.

4. C. Kamaraki et al., Appl. Phys. Lett., 119, 070501 (2021); doi:10.1063/5.0054086.

5. See https://bit.ly/3GOvXFf.

6. D. C. Jordan et al., Prog. Photovolt., 24, 978–989 (2016); doi:10.1002/pip.2744.

About the Author

Jeff Hecht

Contributing Editor

Jeff Hecht is a regular contributing editor to Laser Focus World and has been covering the laser industry for 35 years. A prolific book author, Jeff's published works include “Understanding Fiber Optics,” “Understanding Lasers,” “The Laser Guidebook,” and “Beam Weapons: The Next Arms Race.” He also has written books on the histories of lasers and fiber optics, including “City of Light: The Story of Fiber Optics,” and “Beam: The Race to Make the Laser.” Find out more at jeffhecht.com.