The time involved in cultivating plants can have wide-reaching effects on food production, which in turn can impact food security and ultimately the global food supply chain. A conversion of light could alleviate, and potentially improve, such effects.

Researchers at the Institute for Chemical Reaction Design and Discovery (WPI-ICReDD) at Hokkaido University (Japan), together with a team from the school’s engineering and agriculture departments, have developed a wavelength-converting material (WCM) that when applied to sheets of plastic can convert UV light to red light to enhance the properties of photosynthesis.

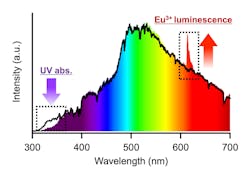

The Eu3+ luminophore with a photosensitizer—hexafluoroacetylacetonato—and a stabilizer—triphenylphosphine oxide (TPPO), [Eu(hfa)3(TPPO)2]—demonstrated a high conversion efficiency from UV to red light; specifically, an emission quantum yield of about 70%, and with almost no absorption bands in the visible light region.

“With our method, we coated the plastic with a paint that contains a high concentration of the luminophore complex, instead of incorporating the complex into the plastic itself,” he says.

Researchers tested the WCM’s capabilities on Swiss chard and Japanese larch trees, comparing the growth of each plant behind coated and non-coated plastic sheets. No significant differences were observed in the Swiss chard during the summer months when the WCM films were used. In winter months, when the sun is weaker and the days shorter, the researchers found that the Swiss chard plants grew 1.2 times larger with the film than without, and produced a 1.4-times greater biomass.

“WCM technology can be used for a variety of plants,” Shoji says. “This advancement could improve the variety and growth of plants cultivated in challenging climates with less sunlight.”

Similar work with boosting plant growth is traditionally done with LEDs. But agricultural films using Eu3+-based WCMs are more promising and could be more sustainable candidates because unlike LEDs, the film doesn’t consume electric power (see video).

“Our method could be useful for a large-scale greenhouse building and for plant production in space where UV light is especially strong,” Shoji says. “We hope to expand on our findings by exploring how changing the molecular structures of the luminescent materials on the film affects plant growth and their production of bioresources.”

The team’s ultimate goal is “to contribute to society by developing eco-friendly and cost-effective sustainable plant production methods for crops, vegetables, trees, flowers, and so on.”

About the Author

Justine Murphy

Multimedia Director, Digital Infrastructure

Justine Murphy is the multimedia director for Endeavor Business Media's Digital Infrastructure Group. She is a multiple award-winning writer and editor with more 20 years of experience in newspaper publishing as well as public relations, marketing, and communications. For nearly 10 years, she has covered all facets of the optics and photonics industry as an editor, writer, web news anchor, and podcast host for an internationally reaching magazine publishing company. Her work has earned accolades from the New England Press Association as well as the SIIA/Jesse H. Neal Awards. She received a B.A. from the Massachusetts College of Liberal Arts.