ULTRAFAST OPTICS: Simple pulse compressor compensates for misalignment

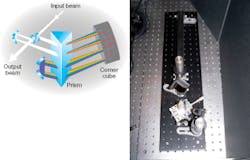

In either case, the slightest misalignment produces all sorts of flaws in the pulse: spatial chirp, pulse-front tilt, angular dispersion, and anamorphism (magnification in one dimension only). Researchers at Swamp Optics (Atlanta, GA) have sidestepped these problems by designing a compact single-prism pulse compressor that passes the pulse through the same prism four times, naturally eliminating misalignments and asymmetries (see Fig. 2). They have built a first prototype from BK7 glass and a second device of PBH71, a much more dispersive glass that makes for a smaller device.

Swamp Optics’ main business is the measurement of ultrashort pulses in time; the company’s pulse-measurement instrument, called GRENOUILLE (GRating-Eliminated No-nonsense Observation of Ultrafast Incident Laser Light E-fields), also measures pulse spatio-temporal distortions, spatial chirp, and pulse-front tilt (see www.laserfocusworld.com/articles/224001). “We find these distortions in almost all of the pulses that we measure in people’s labs,” notes Selcuk Akturk, one of the researchers. “Most of the time, these distortions are introduced by the ubiquitous two-prism pulse compressor, whose alignment and tuning are difficult. The two prisms must be identical and must also have carefully aligned incidence angles. And maintaining the alignment manually requires a lot of patience. Doing so automatically requires a Rube Goldberg-style arrangement of gears and belts, which rarely works well.”

The Swamp Optics design forgoes Brewster-angle incidence on the prisms, which was determined to be not essential, and uses a corner cube to invert the beam, passing it back through the prism in a way that corrects for imperfect alignment. In addition, because the magnification of a beam passing through a prism is the reciprocal of the magnification on return, the total magnification of the single-prism device is identically unity. The device is one-quarter the length of a four-prism arrangement, and half the size of a two-prism version.

Original formula

Back in graduate school, Rick Trebino, the founder of Swamp Optics, had derived a formula for the total dispersion of an arbitrary sequence of prisms in terms of only the prisms’ dispersions and magnifications: the total dispersion is the sum of the individual dispersions, each weighted by the reciprocal of the total magnification that follows it. The formula shows immediately that the single-prism pulse compressor’s total dispersion is identically zero, independent of the prism incidence angle. “We also discovered that double-passing the beam through the corner cube means that any displacement of the device in any direction would result in the output beam remaining perfectly collinear with the input beam,” says Akturk.

“One very common application of ultrashort pulses is multiphoton microscopy, which involves focusing an ultrashort pulse to a tiny spot using a microscope objective and looking at higher-order fluorescence, such as two-photon fluorescence,” says Akturk “The microscope objectives used are usually very thick (several centimeters) dispersive glass. A typical multiphoton microscope can introduce on the order of 10,000 fs2 GDD before the sample. Such a GDD would spread a 100 fs pulse to 300 fs (for an 800 nm wavelength). For shorter pulses, it is even worse: a 50 fs pulse would spread to 550 fs by the same GDD.”

The PBH71-based pulse compressor, which is designed for ideal operation at 700 nm, requires a prism-corner-cube separation of a mere 23 cm to correct for 10,000 fs2 GDD. The prism needs to be tuned by only 10° as the wavelength is tuned from 700 to 1100 nm; this is the only adjustment required as wavelength changes. The company has patented the device and is now commercializing it; a product should be available by October.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.