ED PATTON and BLAIR UNGER

Infrared technology is rapidly evolving for both low-cost consumer applications and extreme-performance applications in defense. A small-format microbolometer array was once many hundreds of dollars-today, one can purchase a complete thermal imaging system for use with a mobile phone for less than $250 (see Fig. 1). Advances in cooled thermal sensors have led to the adoption of wideband or dual-band sensors that combine two wavelengths on the same focal plane, such as midwave infrared/longwave infrared (MWIR/LWIR) for advanced defense systems. These two seemingly disparate markets have one turning point in common: the rapid adoption of chalcogenide optics.

Benefits of chalcogenide glass

Chalcogenide glass is an increasingly important tool for the optical designer, providing a versatile material for many applications—from thermal imaging to hyperspectral imaging.

The properties of these amorphous glasses are useful over a broad spectral range, from the near-infrared (NIR) at 700 nm well into the LWIR spectrum. Chalcogenide glasses consist of mixtures of the Group 16 elements selenium (Se), sulfur (S), and tellurium (Te), and various Group 14 and 15 elements such as arsenic (As), germanium (Ge), tin (Sn), and others.

These glasses are well suited for imaging in the IR regime because of their high transmission, low dispersion, and low refractive-index change with temperature. By changing concentration ratios, glass properties can be tailored for index of refraction, dispersion, glass transition temperature, and other properties. This gives the optical designer or the lens manufacturer more freedom than traditional IR materials.

As traditional IR materials such as Ge and zinc selenide (ZnSe) rise in cost, the use of chalcogenide glasses is becoming more widespread. Chalcogenide materials offer substantial savings today in both the raw material cost and in fabrication methods such as molding technology. They also provide numerous benefits to systems with stringent specifications. There are many sources for chalcogenide glasses, including Vitron GmbH (Jena, Germany), SCHOTT North America (Duryea, PA), and IRradiance Glass (Orlando, FL), which produces a number of glass types along with custom melts.

Meeting the demand for high-volume IR optics

The demand for high volumes of inexpensive IR optical elements, particularly those made of chalcogenide materials, is rapidly increasing as thermal imaging becomes affordable to the consumer. The use of these materials in conjunction with established lens manufacturing techniques presents unique challenges in hitting cost targets.

The processes used for the precision molding of oxide glasses can be transitioned to the chalcogenide glasses. However, variations may exist in process profiles because of the difference in physical properties between the materials. The most notable of these is the lower glass transition (or transformation) temperature exhibited by the chalcogenides. As an example, the transition temperature (Tg) of the oxide glass BK7 is 557°C compared to Tg of 185°C for the chalcogenide IG6/IRG26. This significant delta can have positive effects on the following molding parameters:

- Cycle time: shorter ramp times to achieve required temperatures;

- Tooling choices: more potential materials for optical inserts (cheaper, easier to machine, more readily available); and

- Tooling lifetimes: "softer" glass can cause less wear and tear on surface of optical inserts.

When undertaking a high-volume manufacturing project, consider whether or not the part will lend itself to a multicavity mold configuration. A multicavity molding process is possible and desirable for the small, short-focal-length landscape lenses needed for personal IR imaging devices. The upper limit on cavity number is dependent upon the lens diameter as well as the mold base diameter. Fine-tuning the molding processes to achieve acceptable parts from all cavities is more challenging for a multicavity mold than for a single-cavity mold, but the outcome effectively divides the cycle time per lens by the number of cavities in use and substantially reduces costs.

Precision-molded chalcogenide lens elements made in high volumes present distinct challenges regarding qualification of performance prior to shipment to the customer. Firstly, molded optical surfaces are typically aspheric, which may require the use of profilometry and/or aspheric interferometry, both in line to ensure surface figure and end-of-line testing as specified by the customer, from acceptable quality limit (AQL) to 100% of outgoing product. Secondly, performing any type of transmitted image quality testing requires not only a test system that is acceptable for use in the IR, but also one that replicates the in situ use of the lens in the final product. Lastly, should the customer desire 100% testing at the lens element level, the test system must be able to keep pace with lens production so as to maintain acceptable cycle times at production volumes.

Chalcogenide optics in dual-band IR

The development of dual-band IR sensors that image both MWIR and LWIR on the same image plane challenges the optical designer to create refractive lens systems with one aperture. In the past, classic materials such as Ge and ZnSe have been combined with more exotic materials such as barium fluoride (BaF2) and gallium arsenide (GaAs) to focus light across a wide range of IR wavelengths. Material limitations create unique challenges for wideband chromatic correction. Existing and new formulations of chalcogenide glasses, such as the following types, provide additional indices of refraction and dispersion characteristics for chromatic correction as well as thermo-optic properties for athermalization.

Infrared GRIN materials. The MGRIN program, funded by the Defense Advanced Research Projects Agency (DARPA), has the potential to truly revolutionize the use of chalcogenide glass materials in dual-band systems. Gradient index (GRIN) optics is the branch of optics covering optical effects produced by the gradual and continuous variation of the refractive index within a material. This continuous variation of index not only bends light through the volume of the lens (providing degrees of freedom for aberration correction), but also provides unique and tailorable dispersion characteristics not possible with homogenous material. Such variations can be used to produce lenses with flat surfaces, or lenses that do not have the aberrations typical of traditional spherical lenses. Gradient-index lenses may have a refraction gradient that is spherical, axial, or radial.

Naval Research Labs (NRL) has designed more than 20 different chalcogenide glass formulas for manufacturing IR GRIN optics. GRIN technology will allow the designer to substantially reduce the number of elements in these complex optical designs. Reducing lens count reduces the weight and size of these IR lens systems, but more importantly it reduces the number of surface reflections, improving transmission and range performance.

Infrared fused doublets and triplets. A number of dual-band sensor systems (MWIR/LWIR) have as many as 30 optical elements, and current IR dual-band antireflection (AR) coating technologies produce reflection losses of 1.0–1.5% per surface. When multiplied by the number of surfaces in a system, the total transmission loss can make many designs almost impossible.Even in this small system, this change equates to a system transmission increase of 4–6%. By incorporating a number of fused doublets into more-complex zoom lens systems, these gains can double or triple, leading to a 20% transmission gain and increased performance.

Infrared GRIN optics. Even greater performance gains can be achieved using IR GRIN materials in various forms. There are three basic index profiles for GRIN optics: axial, spherical, and radial. The MGRIN program has worked to develop all three types.

Axial GRIN-the simplest GRIN form-varies the index of refraction along the optical axis, and index does not change with distance from the axis. Axial chalcogenide GRIN is formed by stacking layers of varying compositions together, pressing those sheets together, and interdiffusing the layers to "smear" the concentration profile, creating a smooth transition of composition and hence optical properties over the thickness of the glass.

Spherical GRIN is an index profile that varies radially in all directions from a center point, with surfaces of constant index (isoindicial surfaces) being spherical. Spherical GRIN optics can be produced by bending or shaping an axial GRIN preform via molding.

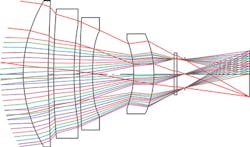

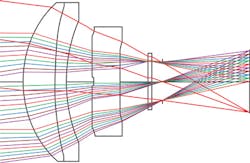

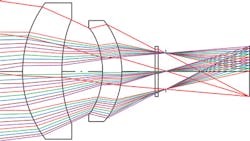

The most beneficial GRIN form in the IR is the radial GRIN. Radial GRIN has an index profile that varies as a function of distance from the optical axis, and the isoindicial surfaces of a radial GRIN form cylinders centered on the optical axis. This type of gradient provides the most optical power for a given change in index. Furthermore, the gradient itself has dispersion properties, and that dispersion is a meta-property that is not limited by the normal dispersion relationships of optical materials. In Fig. 4, two radial GRIN elements do the same work as the original four elements in the 60 mm EFL design, substantially reducing size, weight, and number of surfaces.Molded nanostructures. In addition to the MGRIN program, Rochester Precision Optics also participated in a SBIR II program sponsored by the Army to develop molded micro- and nanostructures (motheye) in both chalcogenide and oxide glasses. The optical properties of chalcogenide optics can be altered by nanoscale surface textures. Antireflective structures that reduce reflectance significantly reduce glare and improve transmission.

Unlike a thin-film coating that creates interference effects, nanostructures are not bandwidth-limited. Hybrid structures have demonstrated performance over dual-band regions (3–12 μm), showing promise for future applications such as high damage threshold for lasers, superhydrophobicity, and antifogging. While these functionalities have been shown on the development scale, there are still great challenges in developing industrial fabrication methods that can reduce the cost of such nanostructured materials.

This rapidly evolving world of high-volume, low-cost IR optics, along with the expansion of extremely demanding dual-band IR applications, has created a requisite for use of chalcogenide glasses. Chalcogenide materials have the ability to be altered and provide optical and systems designers many more options than historic IR material offerings without compromise.

Ed Patton is in business development for emerging technology and Blair Unger is optical engineering manager at Rochester Precision Optics, West Henrietta, NY; e-mail: [email protected]; www.rpoptics.com.