Extruded filters bridge the gap between high performance and low cost

Vacuum-processing methods such as ion-beam sputtering and plasma-enhanced evaporation produce thin-film optical filters with exceptional environmental stability, tight cutoff wavelengths, and tailored spectral bandwidths or reflection values; however, these methods are not easily scaled for volume and require expensive equipment. And although roll-to-roll co-extrusion and nanolamination processes are specifically geared to high-volume applications such as LED backlight distribution, these techniques lack the layer uniformity, complexity, and quality needed for selective optical filtering in higher-end applications, including optics for point-of-care diagnostics and multispectral imaging.

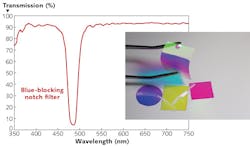

Bridging the gap between high performance and low cost is a new class of extruded thin-film filters from Everix (Orlando, FL). In a process that combines optical-fiber drawing and plastic-film-extrusion methods to provide precise control of layer thickness and refractive index, Everix is producing complex multilayer interference filters for high-volume markets in which laser damage, thermal drift, and narrower operating temperature ranges are not an issue. For example, their 120-layer blue-blocking notch filter has a bandwidth of 20 nm full-width half-maximum and edge slopes of 10–13 nm (approximately 2%) on both sides of the rejection band. This bandwidth enables its use in high-volume applications in migraine relief, macular-degeneration prevention, and reduction of sleep disruption, fatigue, and eye strain caused by LED displays and lighting at a fraction of hard-coated filter prices. In addition to single-notch filters, multinotch, narrowband, and short- and long-pass filters with high optical densities are in the product pipeline. Contact E. Hooman Banaei at [email protected].

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.