One of the most interesting gradient-index lenses is the Luneburg lens, which takes the form of a sphere with a radially varying refractive index; its most well-known version focuses an incoming plane wave to a point at the opposite side of the sphere without any aberrations. Because of the lens' spherical symmetry, this is true for plane waves arriving from any direction. But because the refractive index must vary from the square root of 2 at the sphere's center to 1 at its surface, such a lens has so far proven impossible to build for use in the optical region (although versions that focus microwaves are in use).

But planar (2D) optics can be simpler than 3D optics. Researchers at the University of St. Andrews (St. Andrews, Scotland) have taken advantage of this fact to create a Luneburg lens in integrated silicon (Si) photonic form that focuses near-infrared light.1

Variable-thickness Si

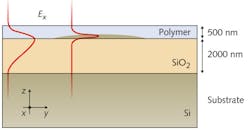

Because doping an optical material to create such a large refractive-index variation is not possible, the lens is constructed by taking advantage of the 3D nature of the waveguide (while ensuring that the propagating wavefront remains 2D). The waveguide itself is a 500 nm outer layer of polymer and a 2000 nm layer of silicon dioxide (SiO2) deposited on a Si substrate. The variation in refractive index within the Luneburg lens is created by introducing a variable-thickness layer of Si between the polymer and SiO2 layers (see figure). The layer varies from 70 nm thick at its center to 0 at its edge and has a 196 μm diameter; the total thickness of the Si lens layer and the polymer layer is kept constant.

The Si lens layer was created using grayscale electron-beam lithography on resist, with the grayscale profile transferred to the Si lens layer via reactive-ion etching. After coating with the polymer layer, the sample was cleaved so that 1550 nm light could be introduced via end-fire coupling. The Luneburg lens was observed from the top under a 50X microscope, showing a high-intensity focused spot at the expected location on the edge of the lens.

The measured spot size was 3.77 μm. Although theory predicts a spot size of about half a wavelength, the actual spot was larger due to the fact that the end-coupled light beam was not a true plane wave, but was instead slightly diverging (±1°), producing an arc length calculated to be 3.8 μm. The researchers also launched a beam of light at the lens at different angles ranging from -4° to +4°, showing that the lens focused light equally well from any direction.

The lens is useful for integrated imaging devices; the researchers say that the variation in refractive index can be large enough to create other radially symmetric perfect-imaging lenses such as Maxwell's fish eye, which images a point at one edge of the lens to a point on its edge diametrically opposite.

REFERENCE

1. A. Di Falco et al., arXiv, 1101.1293, 1 [physics.optics] (Jan. 6, 2011).

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.