Compact singlemode laser is wavelength-switchable at a 0.66 kHz rate

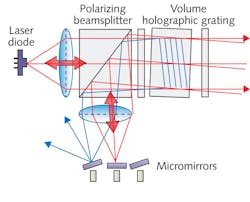

A compact tunable singlemode laser with a 0.66-kHz-rate wavelength-switching speed was created by researchers at Ondax (Monrovia, CA) and the Swiss Federal Institute of Technology Lausanne; the device is based on a cavity formed by a low-cost commercial switchable micromirror array and a multiplexed volume holographic grating with each wavelength assigned to a separate micromirror and a separate volume grating in the hologram. A polarizing beamsplitter and quarter-wave plate couple the light from the laser-diode source into the wavelength-selection cavity with low loss. The thermoelectrically stabilized laser, which is 3 × 3 × 3 cm in size, has a 37 mW output, a maximum linewidth of 7.5 MHz, a 50 µs rise/fall time constant, and a single- or multiple-wavelength output at wavelengths ranging between 776 and 783 nm.

The volume holographic element contains four separate gratings, each at a different angle, and each with a diffraction efficiency of 50% at its appropriate wavelength (the gratings also serve as the laser output mirror). The laser’s output wavelengths of 776.73, 778.43, 780.08, and 783.48 nm can be swiftly selected, either individually or in any combination, with each line operating in single mode. The micromirrors serve as more than just on–off switches—each laser line can also be fine-tuned through a range of a few tenths of a nanometer. One possible use is terahertz generation via photomixing.

Contact Christophe Mose at [email protected].