POLYMER/PLASTIC OPTICS: Optical polymers heal themselves with light

Researchers at Case Western Reserve University (Cleveland, OH), the US Army Research Laboratory (Aberdeen Proving Ground, MD), and the University of Fribourg (Fribourg, Switzerland) have developed a class of optically active metallosupramolecular polymers that are “healed” upon exposure to light, extending their useful life in applications that range from automotive paints to everlasting compact disks.1

Although several-micron-deep cracks and surface blemishes on conventional thermoplastic optical polymers can be healed by heating them above their glass-transition temperature, the process is slow and inefficient, because it involves wetting, diffusion, and re-entanglement of the high-molecular-weight polymer chains. However, these processes can be avoided by exploiting thermally reversible covalent bonds in lower-molecular-mass species such as metallosupramolecular polymers. For these “tough” polymers, heating (with light used to locally apply heat) reduces the viscosity of the materials so that defects can be healed before the polymer is reformed.

Healable polymer recipes

The healable polymers are a macromonomer with a rubbery, amorphous poly(ethylene-co-butylene) core and methylbenzimidazolyl-pyridine (Mebip) ligands. The polymers are self-assembled with either zinc or lanthanum ions (the metallic component) in different ratios that cause a rapid viscosity increase during the creation of the colorless, elastic metallosupramolecular polymer materials. The healable polymers studied are only absorptive below approximately 380 nm (with peak absorption for Mebip-only polymers at 313 nm), while absorption for the metallo-conjugated zinc polymer shifts its peak value to 341 nm.

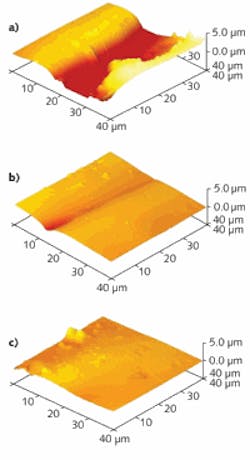

To test the ability of the polymer recipes to heal, the researchers inflicted well-defined cuts in the 350–400-µm-thick polymer films to depths approximately 50–70% of the film thicknesses. The cut samples were then exposed to 320–390 nm ultraviolet (UV) radiation with an intensity of 950 mW/cm2. Although materials with higher metal content did not heal as well, lower-metal-content polymers were healed after two 30 s exposures of the UV radiation (see figure). Despite some coloration changes in the polymer that increased upon longer exposures, the heating—to levels of 220ºC—was concentrated near the surface of the films.

Because the polymer-dopant materials can be changed, the healing wavelength can be tailored to a particular optical application and easily localized only at the site of a defect.

“Our previous studies have really been of a fundamental nature,” says Christoph Weder, professor of Polymer Chemistry and Materials at the Adolphe Merkle Institute of the University of Fribourg. “Now that we have begun to develop a basic understanding for the structure-property relationship of these polymers, we can begin to tailor such materials for specific applications.”

REFERENCE

1. M. Burnworth et al., Nature, 472, 334–337 (Apr. 21, 2011).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.