Scientific Imaging: Near-IR microscopes image through silicon without damaging the finished product

Increasing demand for smaller and thinner electronic parts and devices, coupled with advances in packaging technology for semiconductor devices, are driving demand for maximum resolution in inspection and analysis. A typical microelectronics failure-analysis protocol requires the ability to nondestructively inspect circuit patterns through silicon while maintaining the mechanical integrity of the finished product. If an infrared (IR) microscope is used, system in package (SiP), 3D mounting, chip-size package (CSP), and other configurations and regions that cannot be seen visually can be inspected and analyzed nondestructively.

The requirements of most failure-analysis and R&D laboratories for measuring defects, creating reports, and archiving images demand a digital approach. Because of the nature of this application, native contrast is minimal and must be optimized through image-analysis software. Illumination nonuniformity from causes such as vignetting produces darkening of the image corners relative to the center, and must be digitally removed from the live view and captured image.

While reflected-light microscopy is ideal for illuminating a sample from above, transmitted-light IR microscopy brings light to a sample through silicon from beneath the sample, providing higher contrast. The transmitted-light approach is especially useful for the inspection of alignment patterns or fiducial marks through silicon.

Near-IR inspection

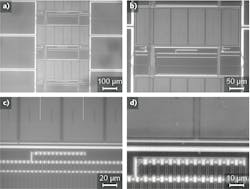

Microscopic imaging in the near-IR spectrum enables inspection directly through silicon up to 650 μm thick (see figure). Applications include inspection for short circuits within the product (burnout marks, stress indicators, and so on), bonding alignment (analysis of alignment marks between thinly bonded circuits), inspection after electrical testing (any type of failure), and chip damage (defects in materials, contamination, etc.). Additional near-IR spectrum techniques and solutions include:

Nondestructive flip-chip analysis. In flip-chip bonding, after the part is bonded, the chip pattern cannot be inspected using visible light. However, with an IR microscope system seeing through the silicon, the interior can be observed without destroying the mounted chip, allowing defect analysis to be performed. This is also effective in identifying the areas that should undergo focused ion beam (FIB) processing.

Wafer-chip CSP. Chip damage that occurs during heat and moisture tests can be inspected nondestructively. Leakage from melting and corrosion of copper wiring, peeling of resin parts, and so on can all be positively observed with through-silicon interior inspection with an IR microscope system.

Silicon gap management. The chip gap in a three-dimensional (3D) mounting configuration can be nondestructively determined by measuring the amount of movement of the objective when IR light is passed through the silicon and focused on the chip and interposer. This method can also be used in the measurement and hollow construction of microelectromechanical systems (MEMS) devices.

Wafer grinding. The thinning of devices by grinding increases the need for measurement of both sides of the wafers. However, measuring the grinding amount on both sides of laminated wafers in the wafer-grinding process is extremely difficult. An IR microscope system can focus on the front and back of the wafer, and the extent of the grinding can be determined by measuring the amount of z movement of the objective.

Advanced imaging using SWIR

Using shortwave-infrared (SWIR) imaging at longer wavelengths—for example, the 1300–1500 nm range—allows for imaging on more difficult samples such as MEMS devices, heavily doped silicon samples, samples with rough surfaces, wafer bonding, and 3D chip stacks. This method is possible using more-sensitive imaging systems such as indium gallium arsenide (InGaAs) cameras. Gaining the signal benefits from dedicated IR objectives, high-power illumination, and InGaAs cameras when using reflected- and transmitted-light microscopy, allowing for imaging on these more difficult samples.

The latest generation of dedicated near-IR objective lenses can provide increased transmittance at the near-IR spectrum and correction collars (for 20x, 50x, and 100x objective lenses) to be set for specific silicon thickness, maximizing transmittance and performance. Digital cameras can provide high-contrast images throughout the near-IR spectrum up to 1100 nm while still maintaining a large field of view. And finally, dedicated software can provide live shading correction to maximize image uniformity across the field of view, perform accurate measurements anywhere within the image field of view, automatically create reports, and archive images and relevant data.

Robert Bellinger | Product Application Manager, Olympus

Robert Bellinger is product application manager at Olympus Corporation of the Americas, Scientific Solutions Group (Waltham, MA).