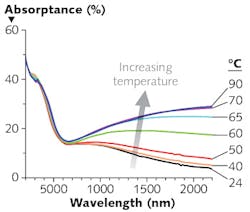

Vanadium dioxide (VO2) reversibly switches back and forth between transparent and reflective states near 68°C because of a metal-insulator phase change—this characteristic makes it attractive as an ultrafast optical switch, for example. In the region around its transition temperature, the refractive index of VO2 also changes, meaning that it could also be used as a tunable-index material. Scientists at the Naval Research Laboratory (Washington, DC) have characterized the tunable refractive index of VO2 by measuring its optical transmittance and reflectance as a function of temperature, and from this data creating wavelength- and temperature-dependent models of the material's complex optical refractive index. The information could be used in the design of future optical devices requiring index tunability.

The researchers grew a high-quality, 35-nm-thick film of VO2 on sapphire via atomic-layer deposition, producing a layer in a monoclinic (020) orientation aligned with the sapphire substrate. A tungsten lamp was then shone on the film at an angle of 6° from normal and temperature incrementally varied between 24° and 90°C, with two minutes of stabilization time between measurements. Changes in transmittance and reflectance were noted in three spectral regions: visible (400–800 nm), near-infrared (800–1100 nm), and infrared (1100–2200 nm). There was negligible scattering loss in the VO2 film. The film's optical permittivity was then modeled throughout the transition region from the metallic to the insulating state. The researchers note that the possibility of conformal and/or flexible VO2 coating with tunable refractive index could lead to novel optical devices. Reference: M. Currie et al., Opt. Mater. Express (2017); https://doi.org/10.1364/ome.7.001697.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.