Two types of edge-emitting diode lasers developed by researchers at the Universität Würzburg (Würzburg, Germany) hold promise for monolithic integration with in-plane devices such as waveguides and beamsplitters. Their secret lies in mirrors that are not cleaved but rather fabricated in a way that allows the lasers to remain part of the semiconductor-wafer substrate upon which they are formed.

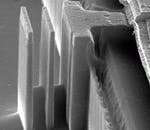

At each end of the first type of laser made by the researchers, deeply etched trenches define a series of slabs that act as distributed Bragg reflectors (DBRs; bottom).

The laser itself, of gallium indium arsenide/aluminum gallium arsenide (GaInAs/AlGaAs) and containing a single-quantum-well (SQW) structure, emits at 955 nm. To avoid absorption, the researchers keep the solid portion of the DBR mirrors thin. With proper etching, slabs with smooth sidewalls and aspect ratios of up to 20:1 can be achieved—features essential to the performance of the mirrors.

Both first-order (period of 280 nm) and third-order (period of 960 nm) DBRs were constructed. The technique allows the fabrication of working laser cavities having lengths ranging from hundreds of microns down to 28 µm, with a cavity length of 80 µm exhibiting the lowest threshold current of 2 mA. Reflectivities of the most recently made DBR mirrors top 80%, according to Johann-Peter Reithmaier, one of the researchers.

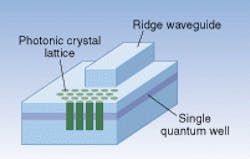

The second type of laser contains a two-dimensional photonic crystal (PC) as one of its mirrors (and an ordinary uncoated cleaved facet as the other). The device is made up of a ridge waveguide formed on a GaInAs/AlGaAs SQW structure; the ridge acts to laterally confine the laser light produced by the SQW. At one end of the ridge, a hexagonal pattern of holes is etched into the underlying SQW structure over an area extending beyond the waveguide and surrounding its end (top).

The researchers experimented with PC lattice periods ranging from 160 to 400 nm, as well as with two different lattice orientations. Good laser efficiency resulted from periods of 300

"The next step will be the integration of short-cavity edge-emitting devices with waveguides based on PCs," says Reithmaier, noting that one potential application is the planar integration of lasers of many wavelengths with combiners and add/drop filters for wavelength-division multiplexing. This could all happen at very low cost in a device the same size as just one of today's edge-emitting lasers, he adds.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.