CONFERENCE REVIEW: MOEMS '99 displays microcapabilities

HANS-DIETER BAUER

MAINZ, GERMANY–The Third International Conference on Micro Opto Electro Mechanical Systems (MOEMS '99), organized by the Institute of Microtechnology Mainz, drew more than 100 participants from the USA, Asia, and Europe to discuss recent problems and developments in this rapidly expanding field of research. A growing number of groups are active in this strongly interdisciplinary field that originates both from microelectronics and micromechanics, as well as from optics.

Interest in MOEMS is driven by the variety of potential applications in optical communications, both in the long-haul and datacom fields, sensors, and imaging. This fact was documented by the large number of talks authored or coauthored by corporate researchers and by the large number of participants from industry.

Evolving applications

Micromirrors—the traditional application of micro-optical actuators—are rapidly evolving. Single mirrors with deflection angles up to 60° and fingernail-sized 32 x 32 arrays were demonstrated. Besides in-plane silicon-based actuators and hinge mirrors, two-dimensional tip-tilt mirror arrays were of great interest. Current arrays show fill factors higher than 90%, and most of the systems can be fabricated by IC- or even CMOS-compatible processes. For example, spatial light modulators (SLMs) with micromirror pixels can be controlled by independently addressable CMOS DRAM cells.

These "matrix switches" are primarily used for realizing optical crossconnects and as devices for scanning and imaging, such as SLMs and adaptive optics. As the capacity of communication networks dramatically increases, the need to manage data rates of 10 or 40 Gbit/s becomes pressing. Switches with 1000 x 1000 crossconnects and moderate switching speeds are within the scope of next-generation network requirements. Therefore, recent development work has been focused on the repeatability, reliability, and robustness of these systems, which are usually regarded as fragile. It can be shown, for example, that silicon-based hinge micromirrors can easily withstand 45 billion switching cycles and the standard drop tests for portable electronics. A repeatability of 0.1° of the light deflection angle can be obtained.

In addition, a series of tunable, wavelength-selective elements are needed in the form of light sources, detectors, filters, and add/drop components. Such elements, fabricated using III-V semiconductor technology, were presented, including wavelength-selective detectors and indium phosphide-based Fabry-Perot etalons made from mechanically moving membranes; both types were built for action normal to the wafer surface.

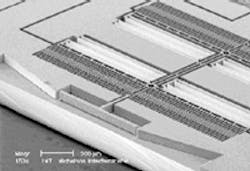

Also of interest was a tunable etalon used inside a mass-producible spectrometer able to detect parts-per-million levels of carbon monoxide. For environmental analysis, two miniaturized Fourier-transform spectrometers were demonstrated, one based on conventional miniaturization and one on silicon micromachining technology (see Fig. 1). Both showed a resolution of a few nanometers. Furthermore, in the field of sensors, new micromachined atomic-force microscopes and scanning near-field optical microscope (SNOM) systems were presented that have been developed with higher scanning speeds (resonance frequency up to 300 kHz) or cantilever-array applications. The optical aperture of SNOM tips made of silicon nitride with aluminum coating can be kept smaller than 80 nm.

Emerging materials

Silicon is still the most widely used material for these microsystems. Nevertheless, polymers play a more and more important role, mainly in the field of passive devices but also for switches; 1 x 2 single-mode fiber switches with an insertion loss of only 0.6 dB were demonstrated (see Fig. 2), as well as 4 x 4 matrix switches that use a concept allowing the deflection of a light signal by total reflection, without moving any mirror plane. Polymer waveguide devices with passive pigtailing based on a modified LIGA (lithographic plating and molding) fabrication technology can be produced in high numbers using injection molding. LIGA also was used to produce micro-optical benches for realizing micro-optical wavelength filters and polarization-diversity receivers.The possibility of high-precision hybrid integration of microsystems and the importance of advanced packaging concepts were pointed out in a number of talks that highlighted the state of the art in microsystem products. While the conventional silicon-based systems-on-chip solution will hold for high-volume products, systems-on-package is regarded as the challenge for MOEMS production in the near future. The proceedings of the Aug. 31-Sept. 1, 1999, conference can be ordered from Hans-Dieter Bauer via e-mail: [email protected].

Hans-Dieter Bauer is director of the optics department at the Institut für Mikrotechnik Mainz GmbH, Germany.