'Fly's eye' lens arrays characterize adhesives

As part of a two-year collaborative project at the National Institute of Standards and Technology (NIST; Gaithersburg, MD) Combinatorial Methods Center, NIST and industry researchers are devising rapid optical screening and measurement methods to speed discovery of new epoxies, pressure-sensitive adhesives, and other products manufactured for the $30 billion global adhesives market.

The pharmaceutical and catalysis industries have developed combinatorial and high-throughput experimental designs to facilitate discovery and reduce time to market for novel drugs and catalysts. The NIST project is one aspect of a growing effort to extend these experimental design strategies into aspects of material science. The NIST approach is based on multilens combinatorial adhesion test (MCAT)—peel-and-wedge test methods that use an array of microlenses to simultaneously measure adhesion at multiple points on a planar surface.1

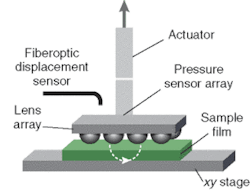

For instance, in one test platform—designed for screening new combinations of components used to make labels, skin patches, and other pressure-sensitive adhesives—an array of up to 1600 microlenses is arranged in a manner similar to a fly's compound eye. The array has an area of 1 cm2. Each lens has a 250-µm diameter, a 22-µm height, and a 366-µm radius of curvature. The lenses are configured in a square grid with a periodicity of 260 µm. Each lens is coated with an incrementally different formulation, and the array is lowered until each lens contacts a waferlike substrate coated with a thin film that also can vary in chemical composition and thickness. The array then is raised until each lens detaches from the substrate (see figure).

In the geometry of the MCAT testbed, the adhesion across the sample film is measured at many points using a lens array. The contact area is visualized through the sample film with an inverted microscope and imagery is captured with a CCD camera. The lens array is mounted to a piezoelectric nanopositioner above the field of view of the microscope. A pressure sensor can be attached in-line with the lens array and actuator shaft to monitor the overall system load, and displacement is measured by at least two fiberoptic displacement sensors.

From measurements of changes in the position of lenses and other preselected variables, researchers can study the adhesive strength of different formulations under varying conditions. A microscope monitors the entire process, and color-coded maps show changes in adhesion energy as lens and substrate bond and then separate. Software-control interfaces provide direct connections between the computer, image software, and instruments.

One challenge with multilens adhesion tests lies in rapidly handling the large volumes of data, according to Aaron Forster, a research chemical engineer at NIST. So automatic software-driven image analysis is used to analyze all the contact areas in the 100 to 500 images (the exact number depends on the test velocity and displacement) of the lens array, which are captured at a rate of two images per second during the attachment and detachment cycle.

For a 1600-lens array, a 2.5× objective can resolve 143 lenses and a 5× objective can resolve 40 lenses. So thousands of individual contact areas must be analyzed in each collection of images, and the quantity of contact areas increases geometrically with inclusion of additional fields of view. Image analysis occurs in two distinct steps: a background image is used to determine the position of each lens within the image, and the experimental images are analyzed to determine contact areas. Methods for characterizing adhesive properties include microscopy, fluorescence, and IR imaging.

Ultimately, the researchers intend to develop high-throughput MCAT peel-and-wedge methods to measure bulk and surface properties of model adhesive formulations, specifically pressure-sensitive adhesives (PSAs) and thermal-curing epoxy-resin systems. Important PSA parameters include composition, relative tack and plasticizer content, blend morphology, and crystallinity. Important epoxy parameters include composition and thermal rate of curing. Industry partners in the collaborative project include Intel (Santa, Clara, CA) and National Starch and Chemical (Bridgewater, NJ), an ICI company.

REFERENCE

- http://polymers.msel.nist.gov/combi/High-Throughput-Methods-Evaluation-Adhesive-Performance.html