JOSEPH ARMSTRONG

Many microscopy applications can benefit from broadband deep-UV (DUV) imaging, some of which also require immersion, cover glass correction, or operation over a wide temperature range. To be suitable for general use, however, microscope objectives need to be small enough to fit into a standard microscope and have a reasonable cost. While traditional microscope optics do not satisfy these requirements, a new catadioptric approach does appear to address them.

Self-corrected objectives with a 0.9 numerical aperture (NA), bandwidth from 266 to 800 nm, and field size of 0.15 mm have been achieved using only seven fused-silica elements. Variations on this design with additional elements have been optimized with many applications in mind including broadband DUV imaging and high-resolution immersion imaging. The designs are also ideally suited for biological applications in DUV fluorescence imaging and spectroscopy, UV resonance Raman spectroscopy, multiphoton-absorption imaging, and optical-coherence tomography (OCT). In addition, the design is insensitive to variations in the glass index, which makes it suitable for applications in which optical performance must be maintained over a very wide temperature range. This can also enable fabrication of broadband microscope objectives at reduced cost using inexpensive materials and replication technologies.

Traditional objectives

Three approaches can be used for microscope objective design: dioptric (refractive), catoptric (reflective), and catadioptric (reflective + refractive). A limited number of the available objectives utilizing these approaches are capable of good performance with high resolution at wavelengths below 400 nm.

Dioptric or refractive microscope objectives are the standard for visible microscopy. High-NA refractive objectives corrected for wavelengths below 350 nm have narrow spectral bandwidths because of the lack of glass types with high transmission and the desired dispersion.

If an objective with a broader bandwidth is desired, a catoptric or all-reflective solution seems to be an attractive option. With this type of objective there is no issue with bandwidth or chromatic aberrations. However, designs like the Schwarzschild two-mirror design, have limited NA, large central obscuration, and limited field size.

By combining several lenses and one or more second-surface mirrors a catadioptric objective can be designed with large field size, high NA, and larger spectral bandwidths than purely refractive designs. But currently available catadioptric objectives are very expensive and have diameters of greater than 80 mm and lengths of greater than 60 mm.1, 2

Small catadioptric objectives

New innovations in the catadioptric design form have allowed small catadioptric objectives to be developed.3 This style of objective is based on the Schupmann medial telescope-a two-lens design that corrects for first-order axial color using a single material. Because the Schupmann telescope forms a virtual image, a mirror arrangement is used in the catadioptric objective to create a real image. The addition of a field lens at the internal field position can reduce chromatic aberration as suggested by Offner in 1969.

A more general solution to achromatizing a three-lens system, which shows better chromatic correction than the Offner solution, can be derived by shifting the field lens away from the internal field. This single-material catadioptric design is also very insensitive to the index of the glass, which allows the design to maintain performance over a wide temperature range. The design has a refractive-index tolerance in excess of 500 parts per million (ppm), which is very large compared to fused silica’s refractive-index temperature sensitivity of approximately 10 ppm/°C.

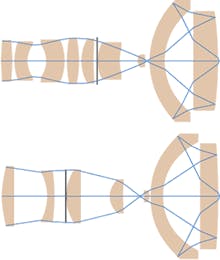

The requirements for NA, field size, bandwidth, and tolerances will drive the design complexity. The length of the objective is set to be less than 45 mm- the distance between the object and the mounting flange on a standard microscope. Many small catadioptric designs, with between 7 and 11 elements, have been developed for different applications (see Fig. 1, top).

In a sample nine-element design, the diameter of the largest catadioptric element is 25 mm. The polychromatic Strehl of this design is greater than 0.87 over the field. The radius of curvature of the surface nearest the object is set to allow rotation of the objective in a standard microscope turret. The design has extra degrees of freedom that can produce many solutions. The extra degrees of freedom are used to reduce the manufacturing tolerances and limit the angles of incidence at each lens surface, which will enable production of the best objective with the least cost. If a somewhat larger obscuration is acceptable, the design can be simplified to seven elements while maintaining the loose tolerances and good performance of the previous nine-element design (see Fig. 1, bottom).

Several standard parameters constrain these designs. The parameters include the focal length, total system length, working distance, NA, field size, telecentricity in object space, and infinite conjugate correction. In addition, an objective has to be practical for general microscopy volume manufacturability at reduced cost. Consequently, these designs focus on reducing the alignment tolerances for the optical elements, which simplifies the time-consuming process of decenter adjustment, and enables the design to withstand mechanical shock more robustly.

Applications

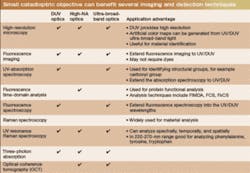

The small catadioptric objective has many potential applications in the life sciences. These objectives can be designed to fulfill requirements driven by a wide variety of detection and imaging techniques (see table). Many standard techniques such as high-resolution microscopy and fluorescence detection can directly benefit through extension into the deep-UV. Some of relatively new techniques including UV resonance Raman spectroscopy, three-photon imaging, and OCT can benefit from broadband capabilities.Many biological applications also have requirements for cover-glass correction or immersion imaging that can be addressed by small catadioptric objective designs corrected from 266 to 436 nm over a 0.15-mm field for a cover glass with a standard 0.17-mm thickness. It is possible to allow for thickness variations in the cover glass by using a rotating collar to adjust an internal air gap. Immersion objective designs corrected from 266 to 800 nm over a 0.10-mm field with 1.2 NA are also possible.

Prototype performance

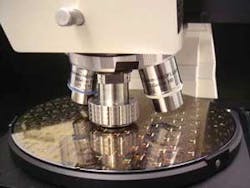

Prototype objectives have been developed to verify performance and manufacturablity. The prototype design has a field size of 0.13 mm and is corrected over wavelengths from 266 to 800 nm. Even though the design can support a broad range of wavelengths, the prototype objectives are limited by availability of optical coatings. The first prototype objective has coatings with optimized transmission from 266 to 436 nm. Later prototypes will test improved coatings to extend the upper wavelength to 550 nm. This prototype objective also addresses other practical issues related to DUV operation and general microscopy. Transmission degradation from DUV photocontamination is a critical problem that must be considered for such an objective. Only qualified low-outgassing materials are used and a nitrogen-purge option is included in the design.

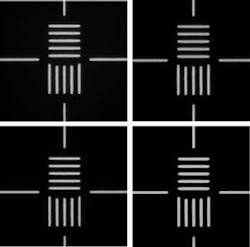

The first objective has demonstrated monochromatic wavefront performance of 0.9 Strehl at 405 nm. The chromatic aberrations have been measured and found to be within manufacturing tolerances. Development and testing of the prototypes continues (see Fig. 2). In addition to the objective, a varifocal imaging system was developed that can continuously adjust from 50× to 300× magnification and that is corrected over the 266- to 800-nm bandwidth of the objective. Images were taken of 0.5-µm lines and spaces taken at 300× magnification using this objective and varifocal imaging system at wavelengths of 266, 313, 365, and 436 nm (see Fig. 3).

REFERENCES

- D. Shafer, Y. Chuang, B. Tsai, U.S. Patent 5,717,518. Washington, DC: U.S. Patent and Trademark Office (1998).

- J. Webb, T. Tienvieri, U.S. Patent 6,560,039. Washington, D.C.: U.S. Patent and Trademark Office (2003).

- Pending patents cover these new design forms as well as their use in inspection and general microscopy.

JOSEPH ARMSTRONG is an engineer in the Corporate Technology group at KLA-Tencor, 160 Rio Robles, San Jose, CA 95134; e-mail: [email protected].