Chirped-pulse oscillators repair photomasks

Semiconductor integrated-circuit (IC) chips are penetrating deeper into daily life, while at the same time becoming more complex and increasingly fine in structure. To shorten current flow paths, speed up clock rates, and increase the number of transistors integrated onto a chip, the minimum feature size of IC-chip structures has dropped well into the nanometer region. Recently, femtosecond-laser technology has been introduced that repairs photomasks damaged by metal splatter, gallium staining, and pitting. This all-optical method also avoids problems created by alternative ion-beam methods, which are currently the main competing technology at sub-100-nm feature sizes.

The pulse energy required is in the nanojoule range—energies only slightly higher than provided by a simple femtosecond oscillator. Chirped-pulse amplifiers (CPAs), which amplify oscillator pulses, are currently in use for this application. A newly developed chirped-pulse oscillator (CPO), however, could be the femtosecond source of choice for this important application in the near future.

Ultrashort processing

Just over 15 years ago, Gérard Mourou and his colleagues at the University of Rochester (Rochester, NY), the Université du Québec (Varennes, Québec, Canada), and the Ecole Polytechnique (Palaiseau, France) discovered that materials interactions with ultrashort laser pulses (picosecond or subpicosecond) were qualitatively different from interactions with the nanosecond laser pulses traditionally used for laser materials processing: the edges looked almost untouched (Mourou is now at the University of Michigan at Ann Arbor).1 This difference in interaction was consistent regardless of the type of material, including biological structures and silicon. Researchers are beginning to understand these interactions in finer detail.

This interaction difference occurs because the energy from an ultrafast laser is deposited on a time scale comparable to thermal dissipation mechanisms. To a molecule or a crystal lattice, a pico- or nanosecond pulse lasts a very long time. The energy is initially absorbed by electrons, but as the pulse continues over the next tens and hundreds of picoseconds, the energy is spread throughout the surrounding area by thermal diffusion. The material at the focus of the laser vaporizes and is removed; the material in its vicinity melts and then eventually cools back down.

This thermal process leads to the formation of a so-called heat-affected zone, which limits the achievable resolution and often leads to problems associated with surface contamination, oxide formation, or lattice modification. In crystalline silicon, for example, the regions adjacent to the actual ablation spots are modified to a polycrystalline state. The precision is further limited by residual damage to the material resulting from mechanical shock waves during heating or cooling, which can leave microcracks or other structural changes in the material.

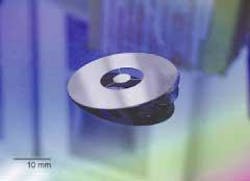

In contrast, the time scale of the ultrashort pulse is 1000 times shorter than for a picosecond pulse, which eliminates almost all thermal effects (see Fig. 1).

The maximum benefits of ultrashort processing are obtained when operating just above damage threshold. Under the strong focusing conditions used to generate structures on the micron or submicron scale, the energies needed to reach thresholds are only in the tens of nanojoules—just slightly higher than the energy level of a standard femtosecond oscillator.

The chirped-pulse oscillator

The CPO is a new approach that solves this problem. It consists entirely of components similar to a standard Kerr-lens modelocked femtosecond oscillator and is pumped by a single continuous-wave Nd:YVO4 (vanadate) pump laser, delivering a perfect beam profile. In contrast to a standard femtosecond oscillator, the CPO works in the positive-dispersion regime; thus, the pulse duration is stretched to picoseconds inside of the cavity, significantly reducing the intensity, and the double- or multiple-pulsing regime is avoided.2

An intracavity multipass cell extends the cavity from the typical 2 m to about 15 m. The low repetition rate transforms the high output power to pulse energies about one order of magnitude higher than those from a standard oscillator. A spectral width of more than 50 nm FWHM (full width at half maximum) centered at 800 nm is generated as a result of high intracavity pulse energy and the control of dispersion over a bandwidth of more than 100 nm with an accuracy of a few tens of femtoseconds by the use of dispersive mirrors (DMs).

The broad output spectrum of the oscillator can be compressed to 30-fs pulses at energies of 100 nJ per pulse or more—ample for work with most dielectric materials. Even under strong focusing conditions, the full average output power can be used and still keep the fluence at the sample just above the damage threshold at 10-MHz repetition rate. A combination of an external prism compressor and DMs corrects for dispersion. As a result, the CPO offers an increase in usable average power by up to four orders of magnitude compared to the CPAs that traditionally have been available.

In confirmation of the pulse quality, using a lens with a numerical aperture (NA) as low as 0.15, surface damage can be achieved with a CPO as a source. Using an aspheric lens with an NA of 0.4, small structures have been created in a BK7 glass substrate. A reduction in pulse energies to just above damage threshold created even smaller structures with estimated diameters of 500 nm.

The tool traditionally used for ultrafast applications has been the Ti:sapphire-based CPA. An oscillator—either Ti:sapphire pumped by a diode-pumped vanadate laser or a lower-power direct-diode-pumped fiber laser—produces a few nanojoules of pulse energy at most. This seed pulse is stretched (chirped) to lengthen the pulse and reduce the peak intensity, amplified in a pulsed-laser-pumped Ti:sapphire stage to bring up the pulse energy to typically around a millijoule, and then recompressed. The pulse width is typically 150 to 200 fs for a fiber-based seed and 80 to 100 fs for a Ti:sapphire seed (see Fig. 2).

Metals and nonmetals

The requirements for materials appear to cover a wider range of possibilities. In metals there are quasi–free electrons (an "electron gas") already available to absorb the incident laser light. An electron temperature is established within a time on the order of a few picoseconds, which is then communicated to the immediate lattice on a comparable time scale.3 Once the lattice temperature reaches the melting temperature, material removal occurs. For metals, sources with pulse durations shorter than this lattice communication time—that is, with pulses on the order of a picosecond—are in theory sufficient to realize the advantages of ultrafast processing. In practice, much higher energy levels can be applied at femtosecond time scales and thus much higher throughput can be achieved in metals.

In nonmetals the situation is fundamentally different—the conduction band is virtually unoccupied, with almost no free electrons available for absorbing incident radiation. To initiate the ablation process, the electric field of the laser light itself has to generate a high density of free electrons in the conduction band.

Because very short pulses are used, nonlinear effects such as multiphoton absorption appear to play an increasingly important role in creating the initial conduction-band electrons. Experimental work has borne this out, showing that the damage-fluence threshold continues to decrease at shorter pulse durations—even down to 5-fs—with less energy needed to be deposited into the material.4

Chirped-pulse-amplifier systems with Ti:sapphire-based oscillators are now available that have pulses significantly shorter than the 100 fs typically used.

In the case of a multipass amplifier, the pulse duration is limited by the spectral width of the seed source only. The use of chirped mirrors instead of prisms to manage dispersion of the seed source produces an amplifier system that can routinely achieve pulses on the order of 25 fs and also leads to a system that has very high stability and efficiency.

At the other end of the pulse-width range, direct-diode-pumped solid-state CPA sources with pulses on the subpicosecond time scale are now being produced. For example, vanadate, Nd:glass, and ytterbium tungstate (Yb:KGW)–based modelocked lasers are now all commercially available.

Although the CPA delivers the highest pulse energies available, for many applications it is limited because of the low repetition rate of a few kilohertz (determined by the pulsed pump laser). This severely restricts throughput, which is important in applications such as microdrilling or cutting in which several hundreds of thousands of pulses are required. In addition, the pulse energy is excessive for many ultrafast-processing applications, such as waveguide writing, and must be thrown away (see Fig. 3). For many industrial applications there is an absolute requirement for higher rep rates up to the megahertz regime, which can be provided by a CPO.

REFERENCES

- J. C. Kieffer et al., Phys. Rev. Lett. 62, 760 (1989).

- A. Fuerbach et al., Proc. SPIE 5340.; Commercial and Biomedical Applications of Ultrafast Lasers IV. Edited by J. Neev, A. Ostendorf, C. B. Schaffer, SPIE, Bellingham, WA, (2004).

- P.B. Corkum et al., Phys. Rev. Lett. 61, 2886 (1988).

- M. Lenzner et al., Appl. Phys. A 68, 369 (1999).

ALEXANDER FUERBACH is a research scientist and ANDREAS STINGL is cofounder and general manager at Femtolasers Produktions, 10-Fernkorngasse, A-1100, Vienna, Austria; e-mail: [email protected], [email protected]. MARY ESSARY is general manager of Femtolasers, 239 Stow Road, Harvard, MA 01451; e-mail: [email protected].