Integrated optical components that produce light at several selectable wavelengths have been realized by lithographic means, according to a team of researchers from the University of Würzburg (Würzburg, Germany), Stanford University (Palo Alto, CA), Infineon Technologies (Munich, Germany), and Alcatel (Paris, France).1 In the semiconductor-laser source, a photonic crystal takes over the functions of cavity mirrors and waveguide.

The device consists of two closely coupled semiconductor lasers equipped with waveguiding cavities, each slightly different in length (see Fig. 1). The lasers have four indium gallium arsenide phosphide quantum wells and a separate heterostructure for confining photons to the plane. Lateral and longitudinal photon confinement are provided by a surrounding hexagonal lattice of air cylinders etched into the semiconductor material. The lattice period of 400 nm and the air fill factor of 30% were chosen such that the structure generates full reflectivity for TE-polarized radiation (which the laser emits) at the spectral band of about 1550 nm (in other words, the photon energy was matched with the center of the photonic bandgap).

The laser-active and waveguiding cavities are featureless regions of seven missing rows of holes in width. Both cavities are separated by a photonic-crystal mirror made of two lines of holes with a reflectivity of approximately 60%. The cavity lengths are 164 periods (114 µm) and 179 periods (124 µm) respectively, giving rise to mode spectra with spacings of 2.9 and 2.6 nm. At the rear facet, the photonic crystal acts as a nearly 100% reflective mirror, while it reflects about 40% at the output end of the combined device.

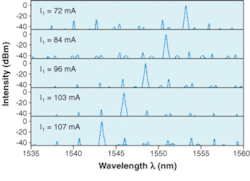

The two lasers are separately electrically injected. By increasing the currents simultaneously, an output optical power of 1 mW is reached at 55-mA drive current per laser (threshold is reached at 12 mA per laser). If not properly tuned, the emission is multimode.

Because of the different cavity lengths, the two resulting mode "combs" have slightly different mode separations. If any two peaks of the mode combs overlap, predominantly single-mode emission occurs. By varying the drive current of one segment and keeping that of the other constant, a discrete tuning is reached for the modes of the second laser segment (see Fig. 2). This can also be done for the modes of the first segment, so that all modes of the two frequency combs can be addressed. When oscillating in a single mode, the rejection of the next-most-intense mode reaches 35 dB. However, frequency tuning influences emission intensity—a drawback for the laboratory device.

REFERENCE

- S. Mahnkopf et al., Elect. Lett. 40(1) (2004).