With the rapidly expanding use of CCD and CMOS image sensors for still and video cameras and the use of digital-image processing software, more and more images are being captured, manipulated, and stored digitally. This in turn has created a strong demand to "deliver" these images in the digital domain directly to screen or paper. To this end, high-resolution spatial light modulators are increasingly being used in display and printing systems.

A spatial light modulator (SLM) consists of an array of optical elements (pixels) in which each pixel acts independently as an optical "valve" to adjust or modulate light intensity. For instance, in World War II–era ship-to-ship communication that used a lamp and shutter, the lamp was aimed at a neighboring ship and a signal operator opened and closed the shutter, which was the SLM, to send Morse-coded messages. Today, of course, the modulation of pixels is accomplished electronically based on image data, essentially converting image information from the electronic domain into light.

An SLM does not create its own light, but rather modulates (either reflectively or transmissively) light from a lamp or laser source to create a dynamically reconfigurable digital image. Technologies that have been used as spatial light modulators include acousto-optic modulators in direct-write lithography systems, liquid-crystal devices in digital projection systems, and MEMS devices such as the digital micromirror device (DMD) from Texas Instruments (Dallas, TX) and the grating light valve (GLV) device from Silicon Light Machines.

Grating light valve

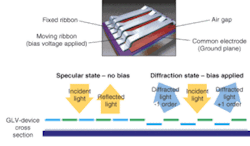

The GLV device essentially consists of an array of dynamic diffractive elements that can switch light on and off, or modulate it to any shade of gray. An array of parallel microribbons is suspended above an air gap and configured such that alternate ribbons can be dynamically actuated. High tension keeps the microribbons taut when not actuated (see Fig. 1). The aluminum top layer of each ribbon serves as both the reflective layer and the top electrode for electrostatic actuation. When a voltage is applied to the ribbon, electrostatic attraction deflects the ribbon downward.

When the voltage of the active ribbons is set to ground potential, all ribbons are not deflected, and the device acts as a mirror. As the voltage to an active ribbon is increased, this region of the array begins to diffract light predominantly into the first-order diffraction lobes, thus attenuating the light that is reflected specularly. As the ribbon is deflected further, the attenuation increases until the deflection of the ribbon with respect to the bias ribbons reaches one-forth of the wavelength of the incident light. At this point the attenuation of the specular reflection is maximum.

To form a complete device, the ribbons are replicated several thousand times to create a one-dimensional array of diffracting elements. The individual diffraction elements are "seamless" in that there are no physical boundaries, or "dark spaces" between elements. Compatibility with CMOS processing facilitates manufacturing using well-tested processes, rapid wafer-lot turn-around time and device development, high yield, tight process tolerances, and automated process monitoring.

Commercial and industrial displays

The most obvious application of SLMs is for digital displays, such as consumer TVs, office projectors, and cinema. Demanding niche applications for digital projectors include flight simulators and command-and-control centers (see Fig. 2). Spatial light modulators are also being used effectively for digital printing. In the commercial graphic arts arena there is a strong desire to go directly from "computer to plate" when making the printing plate for offset lithography presses, eliminating an intermediate film step. Also, as the dimensions of the images on integrated-circuit chips get smaller, the cost of the photomasks is skyrocketing, and a great deal of interest has been generated in the IC industry for a "maskless stepper" that uses an SLM as a dynamically reconfigurable photomask. In the field of optical telecommunication, SLM devices switch optical signals in fiberoptic lines, essentially acting as wavelength-selectable switches rather than SLMs.

In the area of high-resolution display, a one-dimensional array of a few thousand elements has been used to create a two-dimensional (2-D) image with several million pixels. The system works by illuminating GLV devices with a stripe of continuous-wave laser emission. Three devices are used, each one paired with a different laser, one laser for each RGB color (red: 642 nm, green: 532 nm, and blue: 457 nm). The stripe of laser light is reflected off the device and projected onto a screen, where it forms a single column of pixels. The projection optics use a Fourier filter to properly select the desired diffraction order. The devices are fed with HDTV video-image data, and the 2-D image is created by then scanning this column of pixels across the screen to paint the full picture (see Fig. 3).

The ability to create a large 2-D image with a 1-D spatial-light-modulator array allows for a display that is more easily scalable to high pixel counts. Silicon Light Machines used the 1-D scanning architecture to build a 1080 × 1920 HDTV projection system (about 2 million pixels) that uses a GLV device with only 1080 pixels. In this system, each pixel of the spatial light modulator delivers 1920 image pixels (with gray scale) to the screen in 1/60 of a second, for a pixel modulation rate in excess of 100 kHz. In addition, the vertical axis is completely filled as a result of the lack of spaces or physical boundaries between elements, while the horizontal axis is filled by the continuous-wave laser source for an overall 100% fill factor.

To commercialize SLM technology for consumer and industrial displays, Silicon Light Machines has entered into an exclusive relationship with Sony (Tokyo, Japan), and has teamed up with Evans and Sutherland (Salt Lake City, UT) to use the GLV device in high-resolution displays for flight simulators. Flight simulator displays—and the pilots who use them—require superior resolution and emerging technology will enable the production of displays with 20 million pixels.

Printing and so on

In centuries-old offset lithography printing, the plates have been traditionally patterned in machines called platesetters that transfer images onto printing plates using film. A new generation of computer-to-plate (CTP) platesetters uses SLM technology to image the plate directly, eliminate film, and thereby shorten turn-around time and cut material costs.

As in GLV-based display systems, line-illumination from a continuous-wave laser is used. But the similarities end there. Because color in printing is determined by the ink and not by the illumination, only one GLV device is needed and color-space coverage is accomplished by printing multiple plates, one for each color. These CTP systems are based on an IR laser emitting at 830 nm. And because the resist on the plate is thermally activated, high laser powers of 40 to 80 W are used to maintain high throughput. Agfa (Wilmington, MA) and Dainippon Screen (Kyoto, Japan) use GLV modules in their CTP platesetters, and Agfa prints a 1030 × 800-mm plate in about 2.40minutes at 2400 dots per inch, which corresponds to approximately a 10-µm spot on the surface of the plate.

In other applications, Henry Smith, a professor at MIT (Cambridge, MA), with his research group is exploring maskless lithography using a GLV device in conjunction with an array of Fresnel zone plates to print images on wafers (see Fig. 4). On the optical telecommunications front, use of a demultiplexer allows individual channels of a DWDM signal to be spatially spread along the 1-D array of a MEMS-based SLM device. Adjusting the attenuation at each element along the device array allows the power spectrum to be precisely filtered.

Device modules that precisely balance the power levels of all channels in the fiber, enabling higher-quality signals to be sent a longer distance, can act as dynamic gain equalizers to flatten the inherently nonflat gain profile of erbium-doped fiber amplifiers, thereby increasing transmission distances. The technology can also provide a completely flexible wavelength switch in reconfigurable optical add/drop multiplexers (ROADMs). Here, the device is used as a tunable notch filter to selectively block specific DWDM channels while letting other channels pass. These modules enable more efficient routing of network traffic at busy nodes.

ROBERT MONTEVERDE manages product marketing at the Silicon Light Machines subsidiary of Cypress Semiconductor, 385 Moffett Park Drive, Sunnyvale, CA 94089; e-mail: [email protected].