Novel Mirrors: Optical magnetic mirrors operate without metals

Reflection of light from a metal mirror at optical frequencies is accompanied by a phase reversal of the light wave’s electric field due to strong interactions with free carriers of the metal. A “magnetic mirror,” characterized by the reversal of the magnetic field but not reversal of the electric field, has only been proven at radio frequencies using patterned metallic surfaces; to date, however, no natural material is known to produce magnetic reflection at optical frequencies.

Building upon research that has demonstrated magnetic reflectivity using engineered nonmetal materials, researchers at Sandia National Laboratories and the Center for Integrated Nanotechnologies (Albuquerque, NM) led by Sandia scientists Igal Brener and Michael Sinclair have developed an all-dielectric metamaterial mirror with novel properties that could advance the development of light sources, photodetectors, and sensors.1

Tellurium metasurface

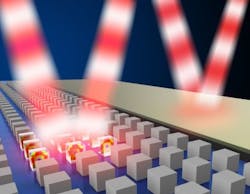

The metasurface comprises a two-dimensional array of high-refractive-index tellurium (Te) microresonators that offer maximal spectral separation of the electric and magnetic dipole resonances (see figure). Numerical simulations were used to guide the optimization of this subwavelength structure to reflect light at infrared wavelengths. For the Te structure, the magnetic and electric dipole-resonance wavelengths (8.95 μm and 7.08 μm) correspond to the absorption maxima of the structure, while the maximum reflection wavelength for the mid-infrared spectrum is around 8.9 μm.

Finite-difference time-domain (FDTD) simulations of the total electric field upon reflection from the magnetic mirror and a conventional gold mirror show the reversal of the electric field at the electric resonance (similar to the behavior of any metal). However, at the magnetic resonance, the phase of the reflected electric field is not reversed; this is the signature of magnetic mirror behavior—a desirable property for advanced sensors or light emitters because it produces large electric fields at the mirror surface that are ideal for coupling radiation into or out of nanoengineered emitters or absorbers.

The two-dimensional array of Te “cubes” (1.5 μm square and 1.7 μm high) with an approximate 50% duty cycle was fabricated via electron-beam lithography and reactive ion etching of Te on a barium fluoride substrate. The amplitude and phase of the electric field of light reflected from the metasurface were directly measured using infrared phaselocked time-domain spectroscopy and compared to identical measurements performed with a gold mirror (see figure).2

For the gold mirror, the results showed the expected reversal of the electric field of the light. In contrast, at the magnetic resonance of the metasurface, the measurements clearly showed magnetic mirror behavior: high reflectivity accompanied by no reversal of the light’s electric field.

“There have been predictions of magnetic-mirror behavior at optical wavelengths using dielectric metasurfaces, but our phase measurements are the first to unequivocally demonstrate this effect,” says Sheng Liu, postdoctoral associate at Sandia National Laboratories. “We are hoping to extend this behavior to even shorter wavelengths for use in solar cells and photodetectors.”

REFERENCES

1. S. Liu et al., Optica 1, 4, 250–256 (2014).

2. S. Liu et al., Appl. Phys. Lett. 103, 181111–181115 (2013).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.