Gold nanocone becomes nonlinear optical point light source

Physicists from the Eberhard Karls Universität Tübingen (Tübingen, Germany) have fabricated subwavelength gold nanocones that serve as nonlinear optical devices. When the cones are irradiated with focused radially polarized near-infrared femtosecond laser pulses, the concentrated electric field that forms at the apex of the cones results in second-harmonic generation (SHG) of light at 387 nm, along with a broadband two-photon-photoluminescence (TPPL) signal. In addition, the green-emitting apex region becomes a point light source with ultrasmall dimensions.

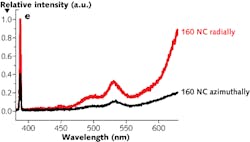

The gold cones were fabricated on glass with a 50 nm thick indium tin oxide (ITO) layer. Spaced 2 to 4 μm apart, the cones have full angles of 50 to 60° and tip radius of 10 nm; cones with heights of 80, 130, 160, and 200 nm were made (see figure; the cone with a 160 nm height is termed 160 NC). Two illumination setups were tried: an oil-immersion objective with a numerical aperture (NA) of 1.49 from beneath the glass and illumination via parabolic mirror from the top. For illumination from the top, the nanocones were illuminated with 100 fs pulses of light at a 774 nm wavelength; a spectrometer CCD camera captured the TPPL and the SHG signals. For illumination from underneath, a spectrometer captured the TPPL spectrum while a separate avalanche photodiode (APD) with a narrowband filter measured the SHG.

The researchers note that for the smaller cone sizes, a signal originating from the base edge of the cones actually predominates, especially in air (measurement from above); for larger cones, the apex is the main emitter. The 200 nm high cones show the highest emission from the apex, with little emission form the base edge. Nanosized light sources such as these can potentially be used in scanning near-field probes or labon-chip sensor applications. Contact Anke Horneber at[email protected].