Photonic Materials: Epner gold: The Midas touch for laser cavities and sensing applications

Gold coatings have long been used on telescope mirrors and within laser cavities due to their high infrared (IR) reflectance and low emissivity. Today, a next-generation, more-resilient gold coating from Epner Technology (Brooklyn, NY) is proving instrumental not only for emerging thermal and IR-reflective uses, but for gas-sensing applications and for advanced laser-pumping schemes based on its unique physical specifications and compatibility with electroforming operations.

Laser Gold

Epner’s “Laser Gold”—the trademark for its gold coating used in improving the output and lifetime of lamp-pumped legacy laser-cavity designs—reaches a hardness of 200 Knoop, which is some 300% harder than ordinary gold plating and even greater than 300% when compared to evaporated gold; quite remarkable when one considers this is gold of 99.99% purity.

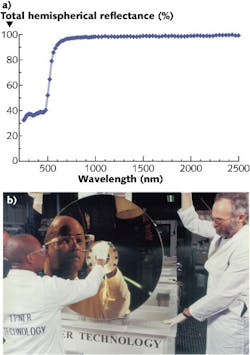

It is this purity that permits the new coating to achieve reflectivity that exceeds 99% at 2 μm and above in the IR spectrum, and only slightly less (97%) at 700 nm (see figure). This combination of reflectivity and hardness made Epner’s coating attractive to the Keck Telescope scientists, where it was specified as the coating on the large beryllium secondary IR mirror since it could be physically cleaned due to its hardness.

The process uses electrodeposition to lay down nanopacked atoms of pure gold. Deposition can be carefully controlled to be as thin as 0.1 μm to achieve an emissivity of less than 0.02 to as thick as 200 μm to permit single-point diamond turning directly on the gold surface. This latter process has produced optical surfaces of less than 50 Å surface roughness.

A reflectance study by Leonard Hanssen of the National Institute of Standards and Technology (NIST; Gaithersburg, MD) involved sending sample boxes containing five different coatings to 23 different optical laboratories. Two of those coatings applied to a specular and a diffuse substrate were Laser Gold. NIST measured the specular substrate at 99% over a wavelength range from 2 to 14 μm and still above 97% at 700 nm. NIST IR reflectance standard mirrors are available from Epner.

The new coating was also specified for its extremely low-emissivity (low-E) performance on 16-foot-long polished stainless-steel tubing that carried the helium coolant for the Mid-Infrared Instrument (MIRI), a critical instrument aboard the James Webb Space Telescope. The Near-Infrared Camera (NIRCAM) aboard the same spacecraft first proved the low-E performance of the new coating on numerous titanium structures. Consequently, plating a thin film of the hard gold on a piece of 20-μm-thick copper foil acts as a thermal barrier that can be applied like wallpaper to the carbon-fiber composite of race-car vehicle bodies, protecting the driver (and car components) from the destructive heat of the engine exhaust system.

Improved gas-detection sensitivity

A new process that combines Epner’s coating with the age-old manufacturing technique of electroforming can increase the sensitivity of IR-based gas analyzers and sensors, which are used to detect carbon monoxide, carbon dioxide, and many other atmospheric and trace gases. In the electroforming process, a compact gas reference cell is “grown” around a highly polished mandrel or tool. After an initial electroplate of Laser Gold, a heavier layer of pure nickel plating is applied that gives structural strength to the gas cell. At this point, the mandrel is removed, leaving a standalone cylinder lined with an IR reflective surface.

“Our original design, a stainless tube with a gold-plated interior, could not achieve the sensitivity our customers required,” said the engineering manager at Servomex (Crowborough, England), a manufacturer of gas sensors. “The shift to an electroform was a minor part of the improved performance. We really got our boost in sensitivity and noise reduction from the Laser Gold that lined the electroform.” This same highly polished, gold-lined cylinder with only narrow slots added can be used as a laser pumping cavity with individual diode lasers looking in through the slots at the laser gain medium.

At SPIE Photonics West 2014, Epner Technology president David Epner was awarded the Midas Award. According to SPIE public relations manager Amy Nelson, SPIE Exhibitions department manager Roberta Hart wanted to recognize David Epner for the continual good cheer, positive attitude, and valuable feedback he has provided to staff. Because there isn’t an existing award for that, Hart worked with SPIE CEO Eugene Arthurs and staff graphic artist Jill Mathews to devise one. The result was the 2014 Midas Award (a nod to the gold-loving king of Greek mythology), presented “for many, many years of exemplary and distinguished gold-coated exorbitance and bemazement.” Of the award, Epner said, “This was essentially a gag put together by the staff of SPIE and presented at the exhibitor breakfast—a kind recognition that at age 81, I’ve been doing these trade shows for longer than I care to remember.”

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.