In the quest to advance research from 100 petawatt (PW) to 1000 PW or exawatt-class lasers, scientists, including Joseph S. Hayden, Simi A. George, and Nathan Carlie from the Research and Technology Development group of Schott North America (Duryea, PA), are collaborating with high-energy-laser developers on innovative approaches to make these lasers smaller, more powerful, and more affordable. With power levels three orders of magnitude higher than state-of-the-art systems like the Texas Petawatt Laser at The University of Texas at Austin, exawatt lasers will have wide-ranging implications for research and technology development in defense and government-funded fields.

A key enabler for exawatt-class lasers is Schott’s platinum-particle-free melting technology, which results in laser glass that permits high-fluence operation without laser-induced damage. For example, large-volume production of slabs with apertures to 40 cm enable high-energy storage for the inertial-confinement fusion program at the National Ignition Facility (NIF), and zig-zag slabs and large-diameter laser rods of high optical quality and homogeneity enable high output powers for laser materials-processing systems.

According to the Schott scientists, most laser experts agree that obtaining laser output at exawatt power levels means decreasing the duration of the laser output pulse while maintaining a large laser aperture to prevent damage from high laser fluence. Instead of choosing materials like Ti:sapphire, Schott is developing neodymium (Nd)-doped phosphate and alternate glass compositions that can tolerate the intense pulses of light and include the improved laser properties needed to create an exawatt laser.

Mixed-glass approach

A mixed-glass laser that uses optical parametric chirped-pulse amplification (OPCPA) on the front end followed by final amplification to energies greater than 1 kJ in Nd:glasses has already been proven at laboratories around the world to reach the 1 PW level with no significant technological bottlenecks.1 Schott laser glass is the second major element needed, enabling the laser designer to maximize gain bandwidth in the Nd:glass stage of the amplifier chain by using two kinds of laser glass (Nd:silicate and Nd:phosphate) to help keep the design simple and manufacturable.

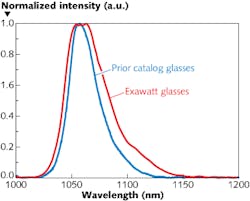

Because the silicate glass has a center transmission wavelength shifted by roughly 6 nm to the red side of the phosphate glass, combining the gain profiles of these glasses in the amplifier chain results in a net gain profile that is broader than either glass alone. Leveraging the mixed-glass technique by developing new laser glasses that exhibit different peak wavelengths and bandwidths to achieve more gain bandwidth can result in shorter pulses and higher peak powers in reasonably large apertures.

Recently, Schott was able to demonstrate an increase of more than 16 nm in the peak emission wavelength separation between phosphate and silicate glasses. In addition, the new glass formulations individually offer up to 30% larger emission bandwidth than current commercial laser glasses (see figure). The increase in effective bandwidth that results in a mixed-glass laser system will allow for pulse lengths less than 100 fs, increasing the available power in a single laser pulse to more than an exawatt.

Why glass?

Reasons for choosing glass over crystalline gain materials such as Ti:sapphire in high-peak-power applications include the ability to precisely dope and manufacture laser glass in large (meter-class) apertures at a reasonable cost (not yet realized in Ti:sapphire) while keeping laser fluence at reasonable levels; the ability to broaden the emission peak and gain bandwidth for sub-100-fs pulses by mixing different glasses; lower polishing and fabrication (melting) costs compared to crystalline materials; and amenability to flashlamp pumping as opposed to laser pumping only for hard crystalline media.

“Multipetawatt to exawatt lasers have the capability to impact many fields; imagine a proton beam that can destroy tumors, neutron sources for improved explosives and weapons detection, and a path to laser-induced fusion energy,” says Eric Urruti, VP of research and technology at Schott North America. “All of these efforts are possible using a surprisingly tough material: glass. We believe these systems will reach production reality in several years.”

REFERENCE

1. E. Gaul et al., Appl. Opt., 49, 9, 1676–1681 (2010).

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.