New modulators fabricated with electro-optic polymers can handle enough near-infrared (IR) optical power to make them practical for transmission of cable-television (CATV) signals. The devices are being developed at Integrated Photonics Technology (Ipitek; Carlsbad, CA). Although the latest-model device requires a half-wave switching voltage of up to 20 V, company researchers say that this could be reduced by half with a few modifications to the design and fabrication process.

Electro-optic switching is generally done using lithium niobate (LiNbO3), a crystalline material that is incompatible with standard semiconductor-circuit and batch-fabrication processes. Replacement of the LiNbO3 by a polymer compatible with such processes would dramatically reduce modulator-manufacturing costs. Researchers, however, have had difficulty concocting a polymer with the appropriate electro-optic properties—high index modulation for low switching voltages—that did not break down modulating high-power signals. The Ipitek devices, however, are made using a new material supplied by AdTech Systems Research Inc. (Beavercreek, OH)—a double-end crosslinked (DEC) polymer containing amino-sulfone chromophores.

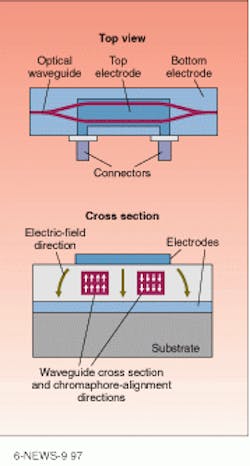

The device architecture is based on the Mach-Zehnder interferometer—an optical arrangement that splits a coherent beam of light into two parts and then recombines them (see figure). A phase difference of introduced between the two beams will cause them to destructively interfere when they meet, thereby switching the output off. Alternatively, a 0 or 2n phase difference will result in constructive interference and a bright output. Changing the optical path experienced by one or both beams of the interferometer will, therefore, modulate the output beam. With integrated optics, this typically means changing the refractive index of two electro-optic waveguides.

To maximize the amount of phase difference introduced with the lowest voltage, the Ipitek devices use a "push-pull" strategy in which the refractive index is increased in one arm and simultaneously decreased in the other, thus doubling the path difference between the arms. Earlier devices achieved this electrically with a separate electrode for each arm—an RF signal would be split and one side inverted to drive the device. The same effect can be achieved with a single set of electrodes by poling the waveguides in opposite directions.

To determine if the DEC polymer was suitable for this kind of modulator, Ipitek researchers first confirmed that it was thermally stable at 100°C and hence compatible with conventional lithography.1 Then they subjected 9-µm single-mode waveguide samples to 40-mW output from a Nd:YAG laser emitting at 1.32-µm—the near-IR wavelength used in commercial CATV transmitters. At an energy of 1012 J/cm2 there was no apparent change in the transmission of the device, although a similar device made from poly(methyl methacrylate) with dimethylaminonitrostilbene (DANS) side-chains lost 10 dB at 1010 J/cm2.

Polymer structure important

The researchers say that the improvement with the DEC material is partly due to the structure of the polymer. Electro-optic chromophores generally undergo chemical reactions when exposed to light at 1.32 µm, and these reactions may be inhibited by the polymer crosslinks. Furthermore, the chromophore itself seems less photochemically reactive.

In addition to testing transmission stability, Ipitek researchers also confirmed that the nonlinear properties of the material did not change. The polymer was tested at the operating wavelength and at 633 nm, with little or no ill effect, although it did break down at shorter wavelengths. At 543 nm, for instance, the electro-optic coefficient dropped dramatically, bottoming out at just 17% of its initial value.

According to Ipitek`s Yongqiang Shi, the designers are trying to improve the fabrication and design of DEC-based devices. The latest models, he says, could be significantly improved if the poling of the waveguides was optimized. Poling is critical because it determines how efficiently an applied voltage is transformed into path difference. Modifications to the architecture are also envisaged. Shi says he expects these improvements to bring the voltage for a phase change down to 10 V.

REFERENCE

1. Y. Shi et al., Appl. Phys. Lett 70 (11), 1342 (17 March 1997).

About the Author

Sunny Bains

Contributing Editor

Sunny Bains is a contributing editor for Laser Focus World and a technical journalist based in London, England.