Gradient-index materials provide alternatives

The properties of axially graduated refractive-index material enable new approaches for solving design problems in optical systems.

Paul K. Manhart

During the past four years, macro axial-gradient-index (AGRIN) lens material has evolved from a curiosity with a novel internal light-bending property to a commercial imaging material capable of achieving f/2.5 spherical singlets with l/50 rms transmission. The transition from crudely diffused glasses to a well-thought-out and well-quantified process for making conventional-sized (macro) lenses required integration of material science, optical design techniques, metrology, theory, and marketing.

Macro-AGRIN lens material is now commercially available, and design software has been implemented into powerful optical-design codes. Nonetheless, widespread use of the material has yet to occur. Designers must deal with practical issues related to its use, as well as choosing between competitive technologies--primarily conventional and aspheric lenses.

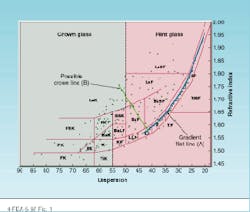

Homogeneous lens material is characterized by a uniform index of refraction and a point on the glass map indicating its dispersion (Abbé number). Axial gradient-index lenses have spatially varying indexes of refraction and dispersion and are represented by lines A and B on the glass map (see Fig. 1). In essence, axial gradient material imparts biaspheric behavior to lenses with spherical surfaces and exhibits a controlled gradient in both index and dispersion. Thus, AGRIN applications range from simple singlet lenses for imaging laser light--in which spherical aberration is eliminated--to complex multiple-element lens systems with improved overall performance.1

Traditional optical systems are based on homogeneous refractive materials with spherical surfaces. A spherically surfaced homogeneous lens will produce images, but with intrinsic optical aberrations. Basic optical principles lead to the use of multiple elements in a lens system to provide imagery across a required field of view with acceptably low aberration content. Spherical surfaces with extremely high accuracy and smoothness can be achieved by several traditional fabrication methods.

Aspheric surfaces make possible improved images with reduced aberrations. The production and testing of nonspherical surfaces, however, are more-complex operations and considerably more expensive than making spherical surfaces. Generally, an aspheric surface will cost about ten times that of a spherical surface. Cost-efficient mass production of optical aspheric elements can be accomplished with plastics or glasses to acceptable accuracy for some applications, but the process is subject to extremely high start-up costs, limited material selection, and small component diameters.

The AGRIN material offers an approach that builds specific aspheric effects into the refractive properties of the material using traditional spherical surface-finishing methods. At the same time, it provides the optical designer with expanded parameters for optimizing performance and cost.

Fabrication issues

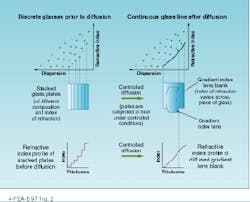

Applying axial gradient indexing to a lens by a fusion/diffusion process involves a combination of steps (see Fig. 2). Macro-AGRIN material can replace homogeneous glass for almost all applications, but designers must determine if such replacement makes sense. They need to ask what is to be accomplished with AGRIN material that cannot be done with ordinary glass and just how cost-effective the AGRIN alternative would be.

The AGRIN technology is currently limited to lead-silicate material in relatively small quantities. If scale-up of the manufacturing process is successful, then costs may drop, making the technology more competitive. But performance improvement, element reduction, and smaller packaging are not the only issues to consider. Knowledge of glass manufacturing and measuring is also important. Gradient material is more complex than homogeneous glass with spherical or aspheric surfaces. Whereas manufactured parameters of conventional lenses can be measured very accurately and the designer can be sure that a lens falls within specification, it is not so easy with AGRIN lenses.

Many important performance aspects of an AGRIN lens lie in the material properties, which are more difficult to measure than surface features. An AGRIN lens with out-of-specification performance is, therefore, more difficult to troubleshoot than a conventional lens.

Ray-tracing time is considerably increased with the addition of each gradient lens. Tolerancing is more complicated because of gradient tilt with respect to the element, vertex depth of the lens within the AGRIN blank, goodness of profile fit, and residual radial terms within the gradient--typically asymmetric and not quantified. Also, efficiency of material use can be low, which drives up cost.

Finally, and perhaps most important, is acceptance from the community. Optical designers and engineers must understand and feel comfortable with all the above issues. They must be educated on details from dispersion modeling to manufacturing and tolerancing. Some applications may also require knowledge of the environmental properties of the material such as the rate of change of refractive index with temperature (dn/dT) as a function of index for a particular glass family.

Characterization of the material is in its infancy and needs to be brought to more stringent levels so that properties such as gradients in partial dispersion, index changes with temperature, birefringence, and coefficient of thermal expansion can be properly quantified. Currently, macro-AGRIN material presents itself as an interesting alternative to aspheres for niche markets (see "Prospects for macro-AGRIN material," above). The inherent three-dimensional complexity of the optical and physical properties of the material, including residual stress, may limit its wide use in optical systems.

The ultimate goal is for an optical designer to approach a design problem and have the choice of using either homogeneous glass or AGRIN glass with equal cost and risk. Then macro-AGRIN material can achieve widespread use. o

REFERENCE

1. P. K. Manhart, Proc. SPIE 2537, 250 (July 1995).

FIGURE 1. Spatially varying index of refraction and dispersion of axial-gradient-index materials are represented by lines A and B on the glass map; homogeneous lens materials, characterized by a uniform index of refraction, are represented by single points on the glass map. (Glass map courtesy of Schott Glass Technologies, Duryea, PA)

FIGURE 2. Controlled diffusion of stacked glass plates of different composition and index of refraction produces an axial-gradient-index lens blank with an index of refraction that varies smoothly across it.

Prospects for macro-AGRIN material

Three possible applications for large-scale (macro) axial-gradient-index (AGRIN) lens material include medical endoscopes, microscopes, and catalog optics. These applications illustrate several design possibilities for this material.

Endoscopes. Medical endoscopes fall into two basic categories--intraluminal (flexible) and free space (rigid). Intraluminal endoscopes have a large field of view. However, the objective exhibits large distortion because of the field of view, and severe barrel distortion is required for the image to look normal. Intraluminal endoscopes are typically flexible and small in diameter. The relay optics are composed of a fiber bundle (for very flexible instruments) or small relay lenses (for semiflexible instruments). Small-diameter AGRIN lenses would require very large gradient slopes, making them potentially impractical for the fusion/diffusion fabrication process. High-quality molded aspheres provide strong competition at this diameter.

Free-space endoscopes are often used inside open cavities with the objective in air, water, or body fluid. Like intraluminal endoscopes, they typically have a large field of view and consequently suffer from distortion. Diameters of these instruments range from about 10 mm for larger laparoscopes to several millimeters for smaller arthroscopes. The relay optics consist of relay lenses in telecentric space. The nature of the objective for these endoscopes is such that good image quality can be achieved throughout the full field of view, but the image suffers from distortion. Aspheric or AGRIN lenses could be used to correct such aberrations.

Microscopes. Medical microscopes for neurosurgery, for example, typically have a long working distance to enable the surgeon to look into deep cavities and to make room for surgical instruments. Industrial microscopes typically have a long working distance for welding or large-scale wafer inspection. Long-working-distance microscopes suffer primarily from secondary color and field curvature.

Short-working-distance microscopes suffer from spherochromatism as well as from secondary color. Spherochromatism is introduced when any one surface is trying to do too much work. Strong cemented surfaces are likely candidates for introducing spherochromatism. One solution for obtaining the very high quality required in short-working-distance microscopes is to go to many elements and some exotic glass for secondary-color correction. Another possibility for some microscopes is the use of strain-free materials with no birefringence. Aspheres are not used in microscopes because the high quality demanded by the objectives cannot be met with molded aspheres.

Most high-quality microscope objectives are diffraction limited across the field of view. High-quality objectives are used with polarization or interferometric instruments, making them sensitive to stress, inhomogeneities, and birefringence. It seems possible that macro axial gradient-index material could be used in microscope objectives that are not sensitive to these factors. It also seems likely that AGRIN components could be used to eliminate spherochromatism and keep element count down.

Catalog optics. Loose optical components and optics assembled for laser and white-light applications are usually referred to as catalog optics and are typically sold through a catalog house. Loose optics, such as singlet lenses, are not extremely high in quality and are used primarily to relay laser light in bench-top setups. First-order optics are usually the primary concern for catalog singlets.

In its current state, macro-AGRIN glass can supply diffraction-limited lens elements ranging from 5 to 50 mm in diameter, at speeds up to f/2.5. Lens assemblies in this size and speed range can incorporate macro-AGRIN material to improve performance. For precision laser focusing, air-spaced doublets or triplets achieve diffraction-limited image quality. Macro-AGRIN singlets can achieve diffraction-limited performance at speeds up to f/2.5, thereby reducing element count and alignment errors, mechanical design, fabrication, and assembly costs.

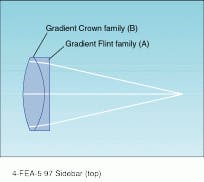

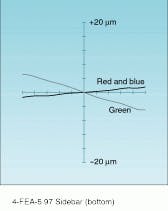

Achromatic doublets can benefit from macro-AGRIN material for speeds faster than f/3.5 and can be used for white-light applications such as achromatic beam expanders and doublets (see figure). Macro-AGRIN material can also be used in diffraction-limited cylindrical singlets for diode-laser arrays and beam shapers. Conventional diffraction-limited cylindrical lenses require a doublet or triplet cylinder assembly or a molded aspheric-cylindrical singlet. The triplet assemblies require three hand-fabricated cylinders and are very sensitive to alignment errors, making them expensive to fabricate. Diffraction-limited performance can be achieved with macro-AGRIN cylindrical singlets. With the demand for diode lasers and arrays growing rapidly, cylindrical AGRIN lenses would seem to be a promising market.

P. K. M.

Using macro-AGRIN material in a doublet (top) eliminates axial color and spherical aberration for white-light applications (bottom).

PAUL K. MANHART is manager of applications development engineering at Donnelly Optics, 1141 W. Grant Road #131, Tucson, A�.