Compared to scanning-electron microscopy, CARS microscopy produces a richer data set and is more conducive to in situ testing of microstructures created using two-photon polymerization, offering an alternative inspection method.

TOMMASO BALDACCHINI and RUBEN ZADOYAN

The ability of coherent anti-Stokes Raman scattering (CARS) to detect signals associated with specific polymerization bonds allows in situ inspection of three-dimensional microstructures and provides more detailed structural information than scanning-electron microscopy, which has been traditionally used to characterize these structures.

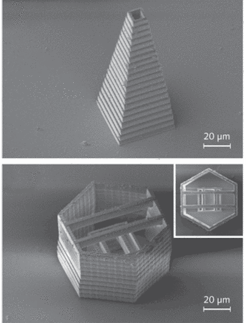

Two-photon polymerization (TPP) is a serial process for fabricating three-dimensional microstructures with resolution less than 100 nm (see Fig. 1).1 The technique uses laser pulses with photon energies too small to excite a photosensitive material (resin) by one-photon absorption. Tight focusing of the beam with a high magnification objective confines the peak intensity in a small volume—and this is sufficient to initiate polymerization by simultaneous absorption of two photons. Accurate positioning of the laser focal point enables fabrication of complex three-dimensional (3-D) microstructures. As long as the solubility properties of the exposed and unexposed resins are different, the unpolymerized material can be washed away—leaving freestanding microstructures on the substrate.

Compared to more traditional microfabrication processes, TPP benefits from a combination of unique advantages, such as sub-diffraction-limited resolution, unconstrained topology of microstructures, and the ability to produce movable parts without the use of sacrificial layers.

FIGURE 1. With the integration of CARS microscopy into the experimental setup, complex three-dimensional structures fabricated with TPP (shown in SEM images) can be characterized and inspected during the fabrication process.

Bright-field transmission-light microscopy is useful for detecting large failures in TPP when negative tone resins are used—because such resins undergo a change in index of refraction upon polymerization. But this method cannot resolve fine details, and it does not enable a 3-D view. Hence, microstructures fabricated by TPP are usually investigated by scanning-electron microscopy (SEM)—a process that provides fine detail but no structural information.

Thinking about a better way

Ideally, in situ monitoring of microstructures during fabrication would provide information about properties of the polymerized material on a molecular level—and measure the “degree of polymerization” (which influences mechanical properties) at different points in the structure. Coherent anti-Stokes Raman scattering microscopy offers these advantages.2

CARS microscopy is a laser-scanning method based on two laser pulses (pump and Stokes). The difference between the two wavelengths is tuned in resonance with a specific molecular vibration. The light interacts with the sample and generates a shorter-wavelength pulse that provides information about the sample’s chemical composition. By scanning the laser beams, a chemically specific 3-D image can be obtained that describes the concentration of the excited molecular oscillators within the sample.

During polymerization of acrylic-based resins commonly used in TPP, carbon-carbon double bonds are homolytically cleaved by the action of radicals, forming multiple new carbon-carbon single bonds. With the use of the right mixture of starting materials, it is possible to form highly cross-linked polymers. Raman spectra of unpolymerized and polymerized samples used in our fabricated microstructures indeed confirm depletion of carbon-carbon double bonds (C=C) in resin appearing at 1635 cm-1 Stokes shift. Thus, it seemed to us, CARS signals associated with C=C bonds could be used as a measure of the degree of polymerization. In addition, Raman spectra of organic materials show strong signals around 3000 cm-1 due to the stretching of both aliphatic and aromatic C-H bonds. Resins used in TPP contain an abundance of these modes, which could also be used to visualize the structures by applying CARS microscopy methods.

FIGURE 2. CARS images recorded at 1620 cm-1 (top) and 1655 cm-1 (bottom) show that relative strength between signals from the unpolymerized resin (background) and the letters can be inverted by tuning the lasers in and out of resonance. The size of each letter is 20 × 25 µm.

null

And testing the “better way”

To validate this approach, we conducted a series of experiments in collaboration with Prof. Eric Potma and his student Max Zimmerley at the University of California, Irvine.3 First, we fabricated simple microstructures using TPP and acquired their CARS images while they were still immersed in the unpolymerized bath of resin. With pump and Stokes wavelengths tuned to excite C=C vibrations, the signal from the area surrounding the microstructures is stronger, while the microstructures themselves appear dark (see Fig. 2, top). When the lasers are tuned away from this resonance the picture is reversed (see Fig. 2, bottom), confirming chemical contrast of the CARS image.

FIGURE 3. A SEM image (top) of a three-dimensional microstructure fabricated by TPP provides high-resolution visual information. A CARS image of the same structure (bottom), produced at 2902 cm-1, reveals the relative strength and weakness, from top to bottom, of the cantilevers.

We then fabricated a series of hanging cantilevers 5 µm wide and 50 µm long, suspended at a height of 40 µm through a rectangular shaped tower; we imaged the structure using SEM (see Fig. 3, top). The five cantilevers were made following an identical procedure. Lines measuring 5 µm (made with a single laser pass) were overlapped side-by-side for the entire length of the cantilever. The only difference in the fabrication conditions used to create the cantilevers was the spacing between the polymeric lines that compose them. In particular, from top to bottom, they are 0.1, 0.2, 0.4, 0.8, and 1.0 µm. While the first two cantilevers are straight and smooth, the last two show ridges on their surfaces. Furthermore, the shape of the last cantilever was distressed during the washing process of the unsolidified resin, highlighting its weakened structural integrity.

To fabricate a sturdy 3-D microstructure using TPP, it is important to know the voxel size when selecting experimental parameters. Voxels are defined as the smallest polymerized volume elements and can be imagined as the “bricks” with which the microstructure will be built. It is the accurate overlapping of these voxels that influences surface topology and, to a certain degree, the mechanical properties of the final microstructure. The surface roughness of the cantilevers can then be easily explained by taking into consideration the relationship between the size of the voxels used and the spacing between the “written” lines. Interestingly, the last cantilever did not collapse completely upon washing of the unsolidified part of the resin although its geometry was significantly affected. This is an indication of a weaker polymer.

A CARS image of the same microstructure was recorded at a height of 40 µm from the surface of the glass substrate to which the microstructure is attached (see Fig 3, bottom). The Stokes and pump beams were set to 1064 and 813 nm. This corresponds to a Raman shift of 2902 cm-1, and hence in resonance with the C-H stretching mode of the polymer. The CARS image clearly shows stronger signals from the cantilevers that were fabricated by larger overlapping of polymerized lines. Furthermore, for the last two cantilevers the CARS signal shows discrete lines aligned with the laser passes used to fabricate them.

A richer data set

The CARS signal is proportional to the square of the third-order susceptibility and therefore strongly dependent on the number of vibrational oscillators. Thus, discontinuities in the CARS signal are a direct consequence of the density variations of the material. The denser the material, the higher the concentration of C-H bonds that give rise to stronger CARS signals.

Although from the SEM images we can deduce that the microstructure is a solid object, the CARS image indicates without any doubt that the density of the microstructure is not homogenous throughout. Because density is related to the polymer cross-linking and polymer total conversion, CARS microscopy in the 3000 cm-1 region allows examination of the elastic properties of the fabricated structure. For a stiffer polymer, for example, it is desirable to obtain the highest amount of cross-linking, which transfers into stronger CARS signal and higher brightness in the CARS image.

Among a variety of approaches for performing CARS microscopy, broadband CARS seems to be the most suitable for integration into TPP workstations.4 Integration is a relatively simple and cost-effective approach—the same femtosecond laser can be used for fabrication and as a pump source for CARS. The Stokes beam is simultaneously generated in a photonic-crystal fiber using only a fraction of the output power of the laser. Galvos can be utilized to scan both pump and Stokes beams to image the structure layer by layer as slow moving precision stages move the sample relative to the stationary laser beam during the TPP fabrication.

REFERENCES

- C.N. LaFratta et al., Angew. Chem. Int. Ed. 46, p. 6238 (2004).

- L.E. Conor and S. Xie, Annu. Rev. Anal. Chem. 1, p. 883 (2008).

- T. Baldacchini et al, Proc. of SPIE p. 7201, 7201Q-1 (2009).

- R. Zadoyan R. et al Proc. of the International Conference Ultrafast Phenomena XVI, Springer Series in Chemical Physics, 92 (2009)..

Tommaso Baldacchini is staff scientist and Ruben Zadoyan is director at Newport Corp.’s Technology and Applications Center, Irvine, CA; e-mail: [email protected]; www.newport.com/TAC.

Tell us what you think about this article. Send an e-mail to [email protected].