LCoS WaveShaper does more than filtering

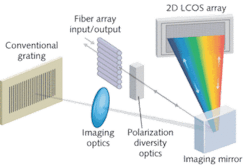

Introduced at SPIE’s Photonics West 2009, the WaveShaper liquid-crystal-on-silicon (LCoS)-based family of optical processors from Finisar (Sunnyvale, CA) offer more than just filtering control for dense wavelength-division multiplexing (DWDM) and R&D applications. The WaveShaper uses a diffraction grating in combination with an LCoS optical processor and polarization optics to control the phase of light at each pixel to produce an electrically programmable grating. The optical input signal overlaps a two-dimensional array of phase-modulating pixels (typically 400 in the vertical dimension), while the spectrum is spatially dispersed in the horizontal direction. Phase-front images are applied to this spatially dispersed signal by the LCoS element, which modulates the phase front of the signal through the voltage-dependent retardation of each pixel.

Because the LCoS controls each wavelength channel independently, the device can provide flattop 50- and 100-GHz-bandwidth filters matching telecommunications-grid, bandstop, sloped, or nonuniform filter shapes. The phase of the image on the LCoS can even be varied along the spectral axis to modulate the group delay across the spectrum, enabling a dispersion-generating or compensating device. This control of the phase and amplitude response of the WaveShaper allows optical Fourier-domain transforms to be easily implemented, enabling controllable pulse-burst generation from a single input pulse as well as the generation of pulses with arbitrary shape including parabolic, rectangular, and sinc functions. Contact Steve Frisken at [email protected].