Random lasers, which combine optical gain and light scattering within an active medium, have been demonstrated using a variety of materials and cavity configurations; however, many of these devices suffer from inefficient pumping of the gain medium. Building on recent work that used titanium dioxide particles suspended in Rhodamine 6G dye within a photonic-crystal fiber cavity, researchers at Centro de Investigación Científica y de Educación Superior de Ensenada and Universidad Autónoma de Baja California (Ensenda, BC, Mexico) and the University of California, Irvine, have demonstrated a one-dimensional (1-D) random laser based on an erbium/germanium (Er/Ge) codoped fiber with randomly spaced Bragg gratings.1 The laser is simply implemented using commercially available fiber and standard fiber-Bragg-grating (FBG) fabrication processes.

“Random lasers can have a large number of modes that are strongly coupled,” said researcher Elena Chaikina. “The consequences of some effects, like mode repulsion, can be easily observed in the laser output, and the coupling between modes can occur even if they do not overlap spectrally or spatially. A unique feature of this optically pumped random laser is that the pump does not interact with the disorder and can excite all the modes. This also improves the efficiency of the emission.”

Fiber Bragg gratings define emission

To fabricate the Bragg gratings, commercial Er/Ge codoped single-mode Er305 fiber from INO (Quebec, QC, Canada; www.ino.ca) with a core diameter of approximately 6.1 µm and maximum absorption of 8.2 dB/m at 1534 nm is exposed to UV light from a 244 nm frequency-doubled argon-ion laser in a conventional FBG masking process. The 10-mm-long mask with a spatial period of 1059.8 nm was used to fabricate approximately 5-mm-long gratings within the fiber spaced somewhere between 4.2 to 5.8 mm apart, with 31 being the maximum number of gratings produced within the fiber for the experimental laser setup.

Grating measurements showed that the FBGs have a narrow reflection spectrum centered at 1535.5 nm and a full-width-half-maximum value of about 0.17 nm. Variations in mask alignment, recording exposure, and fiber tension caused variations in these values, resulting in a bandwidth of roughly 0.27 nm for the array. The reflectivity of each of the individual gratings was 7% to 8%.

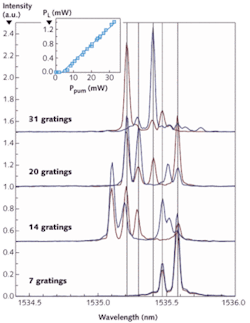

Random lasers were assembled using various fiber lengths with different numbers of gratings and different power levels for the 980 nm laser that end-pumped the random fiber laser. In one example, a 150 cm length of fiber containing seven gratings was pumped at 7 to 10 mW, producing a narrow lasing line at approximately 1535.5 nm when the 10 mW threshold power was reached. As the power moves above threshold to levels of say 20 or 40 mW, additional peaks (or spectral modes) appear.

The number of peaks also increases as the number of gratings increases for the random laser assembled (see figure). Within this range of 20 to 40 mW the peak locations remain unchanged, but the intensity of each peak changes as a function of pump power. Fluctuations in the relative power between the spectral modes are observed, even at fixed pump powers.

Because the lasing frequencies are determined by the particular realization of the disorder, these lasers could find applications in secure communications, as the lasing spectrum provides a “fingerprint” of the source. Due to the simplicity of their fabrication and the possibility of specifying the bandwidth, random lasers could also be used as active elements in photonic devices or circuits. The team plans to continue studies with fiber lasers that have random refractive-index variations in the active region.

REFERENCE

- N. Lizárraga et al., Optics Express 17(2) p. 395 (Jan. 19, 2009).

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.