MANYALIBO MATTHEWS

Lasers have a wide range of uses, including as precision heat sources for welding, cutting, marking, forming, peening, hardening, and more recently, 3D printing. Precise energy deposition also makes lasers useful tools for research in high-energy-density science, particularly at very short pulse lengths and high peak intensities.

In all of the materials-processing applications, the properties of the material and the laser are important. By varying wavelength, power, beam size, or pulse duration, the nature of the interaction can be controlled and fine-tuned. The key to optimizing these processes is to understand the ways in which the laser interacts with, or couples to, the material.

Repairing high-power system optics

These complex laser-material interactions are studied at the Lawrence Livermore National Laboratory (LLNL), which oversees the National Ignition Facility (NIF), home to the world's largest and most energetic laser. The laser system is able to deliver 1.8 MJ of total energy on target with a 3 ns pulse duration at a 351 nm frequency-tripled "ω" wavelength. It has been successfully operated above 500 TW. The laser has 192 separate beams with 35 cm square apertures. The mean fluence is around 8 J/cm2. The beams are focused, reflected, and guided by 40,000 optics.

Overall, the system can amplify emitted laser-pulse energy by as much as 10 billion times and direct it towards a target about the size of a pencil eraser. The laser produces temperatures, pressures, and densities that are similar to those found in the cores of stars, supernovae, and large planets. Astrophysics and nuclear researchers use the laser to better understand the universe, using such technologies as inertial confinement fusion (ICF), where hydrogen fuel is heated and compressed to the point of achieving nuclear fusion.

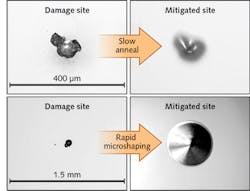

One of the challenges is that routine NIF operations require operating fluences near the laser damage threshold of the optics. The high irradiance levels can damage some of the silicon dioxide (SiO2) fused-silica optics, creating small pits in the surface—similar to the ding you get when a rock hits your car's windshield, but a lot more expensive. The NIF does everything it can to prevent, repair, and recycle the damaged optics (see Fig. 1).

In contrast to the giant laser system in the NIF, which spans three football fields, the lasers used to repair damaged optics are tabletop systems that are integrated with beam- and pulse-shaping components to produce a damage-mitigation system. Our recent research at LLNL focuses on novel techniques for optic repair and more broadly encompasses laser interactions with fused silica or glass.1

Simulating laser-glass interactions

We have used simulation to explore three techniques for repairing damaged optics: (a) infrared (IR) pulsed laser microshaping/micromachining, (b) slow annealing, and (c) laser chemical vapor deposition (L-CVD). Initially, our research focused on the underlying physics and material science of how fused silica behaves when exposed to far-IR laser light at varying temperatures using finite element code developed at the lab.2

The milestones in our temperature-tiered initial campaign included understanding the thermal-elastic response of the material up to the glass-transition temperature of 1300 K; then, examining the molecular relaxation of glass under viscous flow between the transition temperature and the evaporation point at about 2200 K; and finally, investigating the evaporation and redeposition of the material over temperatures between 2200 and 3400 K.

A high-power laser system cannot tolerate much surface roughness in the optics because of beam modulation, which can cause damage to other optics. For example, controlling flatness to such high standards requires extensive simulation. To explore specific techniques for repairing the damaged optics beyond our initial study and to get a hands-on feel for what was going on, we turned to COMSOL Multiphysics. The simulations included heat transfer in fluids, chemical reactions, and structural mechanics, as well as mass transport and fluid flow.

IR pulsed laser microshaping

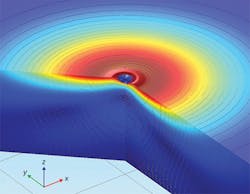

While the simple approach of slow annealing was first used to mitigate optic damage (see top panels of Fig. 1), experimentation and simulation showed that surface rippling caused by thermocapillary flow, or Marangoni shear stress, leads to unwanted light modulation when such surfaces are placed into the laser beam. A simulation showing the laser-induced temperature profile and material displacement because of thermocapillarity is shown in Fig. 2.To counter this effect, we explored the use of short (10s of microseconds) laser pulses to precisely machine material into a shape that is less prone to downstream light modulation when placed in the laser system.

In traditional micromachining of glass, ultrafast femto- to nanosecond pulsed lasers break down and ablate material in a subtractive process. However, this type of machining tends to leave nano- or microfractures that are prone to absorb laser light and further damage when placed in a pulsed laser system. Instead, our development group refined a technique in which an IR laser heats the substrate just beyond the evaporation point, which precisely removes a small amount of material, leaving behind a smooth, fractureless surface. This nanoablation of material is repeated millions of times to produce a smooth, conical-shaped pit, which is "optically benign" in that it does not produce downstream light modulation (see bottom panel of Fig. 1).

Precise control of the process can be exercised by considering temperature-dependent material properties and by choosing the appropriate laser parameter set, especially by tuning the wavelength. Because of the wavelength dependence of the complex refractive index of glass, long-wavelength far-IR light is only absorbed to very shallow depths (less than 1 µm), and so is used to repair surface imperfections. Shorter mid-IR wavelengths, on the other hand, are absorbed up to depths of 1 mm and, therefore, are useful in healing subsurface fractures, such as crack networks.

Despite the long history of IR-laser processing of silica optics, few attempts have been made to understand the energy coupling and heat flow to optimize the process. We were able to answer many of these questions by simulating a wide range of laser parameters and material properties. Results from the simulations for temperature and material behavior in target zones compared well with the team's experiments. What we learned in our research can be applied beyond the repair of damage in our high-energy, pulsed-laser systems to virtually any system that requires laser polishing, annealing, and microshaping of silica surfaces.3

Laser chemical vapor deposition

The third approach we studied for repairing damaged optics was laser-based chemical vapor deposition (L-CVD).3 In this additive process, a silica precursor gas is directed to the damaged surface with a nozzle, while a focused carbon dioxide (CO2) laser beam decomposes the precursor and deposits solid SiO2 glass into the damage pit. L-CVD is being explored to repair large defects on optic surfaces with nanoscale precision that are difficult to fix using IR microshaping subtractive approaches. In principle, the surface figure and optic performance can be entirely restored.

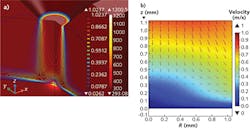

Using simulation, we experimented with how beam intensity, position, and pulse duration affected the amount of material deposited onto the optic. Simulation can determine the concentration and flow of the silica as it decomposes, as well as the location of deposited material (see Fig. 3). In particular, as laser power and deposition rate is increased, the L-CVD process evolves from a kinetic-limited regime to that which is limited by mass transport, strongly affecting the deposition morphology. Simulations guided the optimum point in laser parameter space at which deposition rate is maximized while keeping the morphology well-behaved.Specifically, we found that laser power was a critical parameter for avoiding the unwanted features common in many L-CVD deposition profiles, such as a "volcano"-shaped deposition profile. We were thus able to quantitatively predict both the morphology and deposition rates as a function of temperature.

To date, we know of no other approach that additively repairs damage by replacing lost material with high-grade substrate material. Successful application of such a method could reduce processing costs, extend optic lifetime, and lead to more damage-resistant optics for high-power laser applications in general. In addition, L-CVD can offer advantages for other materials beyond silica glass. The ability to simulate the transient flow, reaction, and heat transport are critical to exploring new applications.

While the L-CVD process is still exploratory for optics refurbishment, the NIF team has implemented CO2 laser-based surface microshaping to help optimize production systems as part of the facility's optics mitigation program.4 Simulation has ensured that LLNL has the correct protocols and expertise in place to address future technical needs. Through 2014, more than 130,000 damage sites have been repaired using the IR microshaping mitigation technique developed at NIF, and the optics are continuously being recycled back into the system to enable routine use of the high-power laser.

Looking forward: Optimizing 3D printing

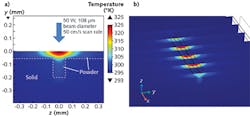

LLNL recently created a lab-wide Additive Manufacturing Initiative.5 We are extending some of our laser processing know-how developed for the NIF damage repair problem to research new methods for the 3D printing process known as selective laser melting (SLM). In SLM, a thin bed of metal powder, tens of microns thick, is placed on a solid substrate. A high-power laser is passed over the powder, melting the powder and some portion of the substrate so that the melted powder is attached to the substrate. Once complete, another layer of powder is added and the process is repeated. Figuring out how to optimize the 3D printing system could have a huge impact on this rapidly growing industry.

We are collaborating with LLNL researchers who have developed mesoscale (micron-level) and system-scale (millimeter-level) SLM models,6 and hope to also use COMSOL models (see Fig. 4) to guide the development of in situ diagnostics and process control.By using simulations across many platforms, the team wants to figure out exactly how the heat flows, how the laser interacts with the powder, how the beam power and size influence the process, and how to come up with new diagnostics and laser technology for SLM.

REFERENCES

1. M. J. Matthews et al., Adv. Eng. Mater., 17, 247 (2015).

2. 4. R. M. Vignes et al., J. Am. Cer. Soc., 96, 137 (2013).

3. M. J. Matthews et al., SPIE Laser Damage, 8885, 888526–888526-9 (2013).

4. J. Folta et al., SPIE Laser Damage, 8885, 88850Z–88850Z-9 (2013).

5. See https://manufacturing.llnl.gov/additive-manufacturing.

6. N. E. Hodge et al., Comput. Mech., 54, 33–51 (Jul. 1, 2014).

Manyalibo Matthews is deputy group leader in the Materials Science Division of the Lawrence Livermore National Laboratory (LLNL); e-mail: [email protected]; https://pls.llnl.gov/people/staff-bios/msd/matthews-m.