Nanometrology: Get the most out of your microscope by understanding your site environment

Maximizing image resolution is critical for microscopy of all types. Achieving this goal is often predicated on the operator's ability to decouple the instrument from ambient environmental conditions such as vibration, acoustic, and electromagnetic noise. Not all instruments are sensitive to these environmental factors, but for instruments that are sensitive (such as scanning electron microscopes, atomic-force microscopes, and various types of optical microscopes), they become severely limited in their ability to retrieve quality data if environmental-isolation systems (such as vibration-isolation platforms) or other mitigation techniques are not in place.

Measuring and analyzing environmental noise becomes critical when new instrumentation is being installed. Not only does measuring environmental noise inform the end user whether a prospective installation location is suitable for the soon-to-be installed instrument, it also helps define what level of environmental noise reduction is required for the instrument to operate at maximum utility (see Fig. 1). The data may also encourage the end user to consider alternative locations or compare data from two measurement sites to determine the preferred operation location.

Developing this foundation of knowledge saves the end user time and money by eliminating the need to wait for mitigation techniques to be put in place to make a sensitive instrument operable. Understanding this critical information in the beginning and preparing for it accordingly enables the end user to focus on research immediately, rather than delaying due to constrained equipment.

Performing or receiving a site survey: Know your options

Instrument manufacturers have varied approaches when it comes to providing site surveys as a service, as well as getting the information to the end user. The most common implementations of this service include instrument manufacturer supplying the site survey, environmental consultant supplying the site survey, or the end user being tasked with the job of characterizing the environment directly. All three scenarios revolve around the notion that a location is being evaluated for an upcoming instrument installation. It is important that this responsibility be known during the discovery phase of the instrument location, as having to source a site survey after an instrument has been installed can lead to weeks of delays and potential higher costs as a result of expedited services or equipment being required.

Instrument-manufacturer-supplied site survey. In the most-common approach to determining the environmental noise of a location, an instrument manufacturer performs a site survey at the customer location. After the instrument configuration has been decided by the end user, the instrument manufacturer then has a sales engineer visit the installation location with the site survey equipment to perform measurements. The data is then compared against the environmental specifications of the prospective instrument, highlighting any environmental noise that exceeds the maximum allowable noise specifications of the instrument (e.g., measured noise: 20 μm/s at 20 Hz; environmental specification: 10 μm/s from 0 to 30 Hz). If the environment does not meet the noise specifications of the instrument, mitigation techniques are recommended or a new site is proposed. The costs associated with this service are often absorbed by the instrument manufacturer as a means to facilitate the sale of the instrument, or are reimbursed to the instrument manufacturer once the instrument has been purchased.

Environmental-consultant-supplied site survey. When the instrument manufacturer does not have the internal framework to perform the site survey directly, it is common for the manufacturer to contract a third-party environmental consulting company to perform the service. Contracted environmental consultants are often familiar with the instrument's specifications and understand the proper measurement parameters needing to be taken. The cost of this service is also typically absorbed by the instrument manufacturer, whether it be upfront service provided for free or reimbursement once the instrument has been purchased.

Environmental consultants also support end users directly without the recommendation of the instrument manufacturer. The industry of environmental consultants supplying site surveys is vast, but not all cater to the specific needs of every microscope user. Knowing the scope of the consulting firm is critical in ensuring that the data being measured, analyzed, and reported is relevant to the instrument being installed. When selecting the appropriate environmental consulting firm, ensure that it is familiar with the instrument's environmental specifications to confirm that the hardware used by the consultant is capable of providing that information, as well as that the methodology of the software is in line with the results required. Since the consulting firm does not have the sales incentive to waive its fee for this service (when contracted directly by the end user), purchasing a site survey from one of these companies is typically seen as the most-expensive option for end users wanting to measure noise in their environment.

End-user-supplied site survey. When funding is short or the instrument manufacturer does not have a service framework in place to provide a site survey, it is common for end users to source the data themselves. Site-survey tools vary dramatically in terms of the features they provide as well as in the complexity of the interface and hardware. For end users interested in a one-time room measurement, purchasing a complex measurement tool is often not the advisable approach, as kits become rather costly once additional features and sensors are included. More-affordable solutions for one-time measurement needs include renting a site-survey tool, evaluating a site-survey tool, or having a third-party consultant perform a site survey. Should there be opportunities in the future where site surveys will be required, purchasing a streamlined surveying tool focused on taking quick and easy measurements (for example, the WaveCatcher) is a more cost-effective solution than continuously renting the tool or contracting a company to perform the site survey.

Information you need to maximize your instrument

When the environment is unknown for an end user, knowing what to look for and measure can be daunting. The recommended first step is to evaluate the environmental specifications of all incoming instrumentation to understand the maximum allowable environmental noise of the room. These specifications are thoroughly researched by instrument manufacturers to ensure the instruments are capable of maximizing the quality of the data generated. Once these specifications are known, the data from a site survey will need to be compiled and compared against the specifications to understand whether the ambient environmental conditions meet specification. If they do, no further action is needed and the instrument can operate freely as long as new noise sources are not introduced into the environment. If the measurement site does not meet specification, mitigation techniques are then recommended and often required. Having this knowledge prior to the installation of an instrument is critical, as the preparation of mitigation solutions while the instrument is being built prevents delays of research.

Once the data has been measured and analyzed for the customer's upcoming instrument, there are several options for mitigation techniques that vary in terms of costs, effectiveness, and complexity.

Architectural modifications. The most complex and costly mitigation process is modifying the architectural properties of the installation site (such as reinforced acoustically insulated walls, false floors, reinforced support columns, and so on). This process is not always available, as many facilities and universities have complex processes to make such changes, making this opportunity more feasible for new or recently renovated buildings. If modifications are being made in a new building, the ambient environmental properties are not yet finalized, meaning that what is measured during the construction phase of a building will not be the exact properties of the final instrument location. Having extensive knowledge of the surrounding area and nearby machinery is critical in understanding potential issues that may arise after the site has been finalized. It is common for multiple site surveys to be performed to ensure the operating conditions for the instrument are well known.

Moving instrument installation locations. The simplest solution often highlighted by performing a site survey in multiple locations is to install the instrument in the site with the lowest noise floor (typically the basement or floor supported by the ground). If this option is available, end users have a nearly free solution in defining where their instrumentation will be used. The unfortunate reality is that this is not always an available option due to the crowded nature of research facilities and the limited available space for new instrumentation. When possible, this is the recommended solution by instrument manufacturers and end users, as it saves time and money in having to find a more complex solution to mitigate environmental noise. When this is not possible, isolating the instrument or the noise source is the recommended course of action.

Decoupling noise sources from the environment. When performing a site survey, the sources of noise in the environment are often known, along with the extent in which they are affecting the environmental characteristics of the site. During a site survey, it can be determined how much of an impact a noise source can have on a site by removing it from the room to perform a measurement. If the noise source cannot be removed from the room once the instrument has been installed, basic vibration, acoustic, and electromagnetic interference (EMI) isolation systems can be used to limit the impact of the noise source on the instrument (such as anechoic chambers for acoustics, sorbathane mounts for vibrations, and so on).

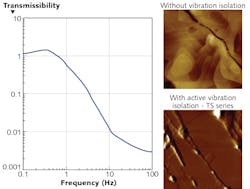

Environmental-isolation platforms. The last and most-common solution for instrument manufacturers and end users is to use an environmental-isolation platform to support the instrument directly (see Fig. 2). Whether it be an active vibration-isolation platform or an acoustic enclosure, isolation platforms enable users to operate their instrumentation within the provided working area while achieving maximum data quality from their instrumentation. A key metric in choosing the right isolation platform is to compare the level of isolation the platform can provide with the problem frequencies of the environment and the measured maximum amplitudes. If the platform can bring the instrument to within specification, then the solution has been found. If not, then alternative mitigation techniques as described above will need to be taken.Working together to advance research

The end goal for instrument manufacturers and end users will always remain the same: delivering a solution that maximizes the utility of the research and instrument. When an instrument is operating in optimal environmental conditions, both parties get exactly what they set out to do. This journey of understanding, analyzing, and mitigating environmental noise is a core part of the discovery process for instrumentation and becomes a vital component for researchers wanting to expedite the results of their research through controlling their environment.