Ophthalmology: Liquid-crystal contact lens electrically varies through 2 diopters

While many types of liquid-crystal (LC)-enabled eyeglasses—which allow varying their focus electrically—are under development (with some versions already on the market), the next step in the evolution of LC technology for vision correction is to create variable-focus LC contact lenses. Putting aside the difficulties of providing wireless electrical power and control to lenses placed on the surface of the eye, the problem remains of how to effectively produce enough variation in focus while keeping image quality high and applied voltage down to reasonable levels.

Researchers at the University of Dhaka (Dhaka, Bangladesh), the University of Manchester (Manchester, England), and the University of Leeds (Leeds, England) have developed an LC contact lens that contains a homeotropically vertically aligned LC configuration, which provides high optical quality with a simple structure and low applied voltages.

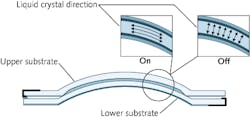

Because an LC device—which contains LC material between two pieces of plastic—typically relies upon the directional qualities of the LC material being electrically switched to produce changes in the optical parameters (in the case of a contact lens, the refractive index), the LC material must be aligned to one or both pieces of glass, typically by rubbing the plastic with cloth before assembly of the device to produce microscopic grooves in the plastic. A heterotropically aligned LC device requires rubbing both surfaces, while a homeotropically aligned LC device only requires one surface to be rubbed.

There are two advantages to a homeotropic configuration. First, a contact lens made to hold an inner LC layer has two elements, one with a convex and the other with a concave surface. While rubbing the concave surface is straightforward, uniformly rubbing a convex surface is more difficult. As a result, homeotropic alignment allows the fabricator to choose only one surface (the concave) to rub. Second, homeotropic alignment means that no subsequent relative rotational alignment of the two elements is needed.

Two types of polyimide coatings

The two optical elements of the new contact lens are made of PMMA, a material often used for contacts—the LC sandwiched between them forms a negative meniscus lens (see Fig. 1). The concave outer surface of the assembly has a radius of curvature of 7.8 mm, which is the same as that of an average human cornea. The researchers chose a nematic LC material called MLC-2081 because it has a high birefringence (producing high focus change) and a high dielectric anisotropy (leading to low required voltages).

In the lens design, the change in refractive index of the LC as a function of applied voltage allows continuous variation of the overall optical power of the device between +0.25 and -1.75 diopters over a range of voltages from 2 to 7 V.

To fabricate the device, the PMMA substrates were turned to shape on a lathe, then coated on their inner surfaces with indium tin oxide (ITO), a transparent conductor, to form the electrodes. Next, polyimide was coated on top of the ITO layers; the concave surface received one type of polyimide that supported rubbing to create alignment grooves, while the convex surface received a second type of polyimide that did not itself align LC material (allowing the other surface to do all the alignment). After baking the substrates at 60°C for two hours, the concave substrate was unidirectionally rubbed with a velvet ball to create the required alignment surface.

Using a polarizing microscope, the researchers qualitatively assessed the alignment quality of the LC in the contact lens, viewing the lens assembly under the microscope while applying an alternating voltage to the LC layer. In addition, the optical and resolving powers of the lens were quantitatively measured using light at a 589 nm wavelength from an expanded laser beam, a polarizer, and a CCD beam profiler. The point-spread function (PSF) of the lens was measured and the modulation transfer function (MTF) calculated from the PSF results.Results showed MTF50 values of 1.39 and 1.00 line pairs/mrad at root-mean-square (RMS) voltages of 0 and 5.7 V, respectively (see Fig. 2). For the upper and lower substrates themselves, MTF50 values were 1.84 and 1.25 line pairs/mrad, respectively. For comparison, the MTF50 of a diffraction-limited system was 3.17 line pairs/mrad. The researchers note that many LC lens geometries are possible, allowing correction for differing eye problems such as presbyopia.

REFERENCE

1. I. M. Syed et al., Opt. Express; doi:10.1364/OE.23.009911 (Apr. 9, 2015).

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.