Simple metamaterial allows arbitrarily sharp waveguide bends

A proposed method of using a metamaterial to permit very sharp low-loss bends in waveguides shows how cleverness can result in simplicity. Previous modeled approaches have relied on transformation optics, which require the use of anisotropic and/or inhomogeneous metamaterials that would be impractical to fabricate. The new approach, developed by researchers at the Harbin Institute of Technology (Harbin, China), uses only homogeneous, isotropic metamaterials that can be made now for the microwave region (the region of the simulation), and are much more feasible for the optical region.

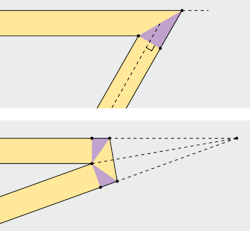

Most of the waveguide is a bulk dielectric (yellow); at the bending corner, a small prism of impedance-matched metamaterial (purple) with a negative refractive index is inserted (left). For extreme bending angles, two small prisms are inserted instead (right) to eliminate the resulting long tip. The simulation was done at 6 GHz (equal to a wavelength of 5 cm) for a 5 cm wide waveguide (but easily translatable to narrower waveguides at higher frequencies). The properties selected for the metamaterial depend only on the dielectric properties and thus remain the same for all angles. The fabrication of a suitable optical metamaterial would allow very compact, low-loss photonic circuits to be created. Contact Weiqiang Ding at [email protected].