BIREFRINGENT OPTICS: Biological quarter-wave plate is highly achromatic

Quarter-wave retarders (quarter-wave plates) are very useful in optical systems, in particular because they can convert linearly polarized light to circularly polarized light, or vice versa. In just one example, illumination light in an optical system can be passed through a linearly polarizing beamsplitter and then through a properly oriented quarter-wave plate before it exits the system. If the light then specularly reflects off an exterior object back into the system, the light passes again through the quarter-wave plate and is converted to linearly polarized light; however, the polarization is rotated by 90° to that of the exiting beam.

This forces the beamsplitter to completely reflect the incoming light to the detector, as opposed to transmitting part of it back to the light source. For a polarized light source such as a diode laser, the efficiency of this setup can approach 100%; in contrast, the use of a simple partially transmitting beamsplitter to direct the incoming light to a detector can never be more efficient than 25%. Thus, quarter-wave plates are crucial to optical systems such as CD and DVD drives, as well as microscopes, where high efficiency is key.

Quarter-wave plates are also valuable in certain imaging systems because they can be used to reduce glare and specular reflections in the field of view. But, due to limitations of the material they are made from, conventional quarter-wave plates only correct perfectly at one wavelength. Improved designs, some of them based on subwavelength structures, can be made to be partially achromatic over a certain range.

Crustacean optics

Now, scientists have analyzed a quarter-wave plate found in nature—a layer of cells within the compound eye of a stomatopod (an underwater crustacean)—and discovered the layer has better achromatization than does manmade quarter-wave plates.1 The subwavelength structure of the eighth-retinular-cell (R8) layer, combined with its birefringence and refractive-index dispersion properties, result in achromatization across the entire visible spectrum.

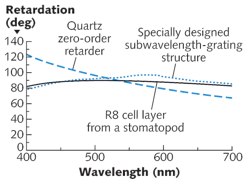

A comparison between a conventional quartz zero-order retarder, an optimized subwavelength grating (SWG), and the R8 layer was done over the 400 to 700 nm wavelength range (see figure). While the SWG, with a ±9.1° variation from the ideal quarter-wave retardation, looked quite a bit better than the quartz plate, the R8 easily bested them both with a ±2.7° variation—a factor-of-three better.

By learning from the stomatopod eye, it may be possible to create better synthetic retardation optics, say the researchers. The creation of new types of optics that combine microscopic polarization and spectral detection with control of transmitted polarized light control could also be feasible, they note.

REFERENCE

- N. W. Roberts et al., Nature Photonics 3(11) p. 641 (November 2009).

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.