An optically pumped room-temperature vertical-external-cavity surface-emitting laser (VECSEL) developed by researchers at the Institut d'Electronique du Sud, Université Montpellier (Montpellier, France) and the Laboratoire de Photonique et Nanostructures (Marcoussis, France) reaches an output of 2.1 W of low-noise (37 kHz linewidth), single-frequency TEM00 operation with a beam quality (M2) of 1.2 at a wavelength of 1015 nm. The high beam quality was achieved even though the laser was pumped with a low-beam-quality, multimode fiber-coupled, angled diode-laser beam (at 808 nm).

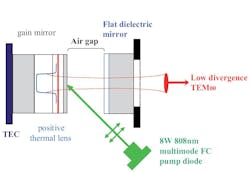

The VECSEL contains six strained indium gallium arsenide/gallium arsenide phosphide quantum wells, a high-reflectivity Bragg mirror, an antireflection coating, a thermoelectric cooler (TEC), and an external flat dielectric mirror. The cavity length could be varied between 3 and 10 mm; maximum power was achieved for a 5 mm cavity length and 8 W of pump power. The laser structure formed a thermal lens under operation, but the cavity operated as a single-transverse-mode optical resonator. The researchers believe that the laser's noise and linewidth can be reduced further by using electrical pumping or low-noise optical pumping, and also that larger active diameters will lead to higher output powers. Contact Arnaud Garnache at [email protected].