Rod-shaped gradient-index (GRIN) lenses are commonly used to couple light into and out of optical fibers. Such lenses have a refractive-index profile that varies parabolically with radius and are usually fabricated with flat end faces. Thin-film optical filters—such as tap, edge, wavelength-division-multiplexing, and coarse-wavelength-division-multiplexing (CWDM) filters—are commonly used with GRIN lenses in telecommunications. Typically, thin-film filters are deposited on a separate glass substrate, then combined with GRIN lenses to construct three-port couplers and modules. These devices are often assembled manually through tedious alignment and production steps, including epoxy bonding to attach filter chips to lenses.

null

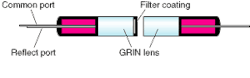

Engineers at NSG (Tokyo, Japan) have eliminated the glass filter substrate by developing filter-on-lens technology (FOL), in which thin-film coatings are sputtered directly on the end face of the GRIN lens to produce a single integrated device (see figure). Historically, the thermal-coefficient mismatch between lens and coating materials has made this process difficult. But adjustments made to the coating process have enabled NSG engineers to create monolithic tap, edge, and CWDM couplers with their FOL process. The integrated nature of these devices means that lens and filter alignment do not change appreciably over time, temperature-dependent loss is low, and two Fresnel losses—one at the lens and another at the filter—are eliminated.

The single integrated subassembly reduces production steps by eliminating the need to align, assemble, and cure the filter subcomponent. The result is fewer inspection steps, reduced handling of the optics, and a lower risk of lens contamination. Because FOL technology eases x-y axis alignment tolerances in the production of three-port assemblies, it is well suited for automated assembly. The FOL lens/filters themselves are currently undergoing the final stages of reliability and performance testing; NSG manufacturing sites are gearing up for high-volume production.