IAIN MACMILLAN

High-power thin-film optical coatings are typically required for optics that must handle sustained high-power output from lasers. These coatings can be reflecting, transmitting, polarizing, or beamsplitting; it is important to note that "high power" may have different meanings depending on the application. A reasonable definition is that the term "high power" applies to any coating that requires special attention and processing to avoid damage during irradiation. As a rule of thumb, any design drawing that includes a power specification (that is, for which the standard processing is insufficient) is considered a high-power coating.

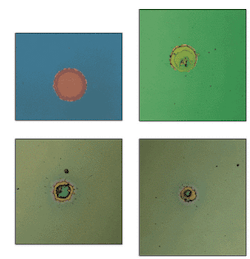

The optical coating is generally the limiting factor in the output of a high-power laser system. The most common failure mode of high-power laser coatings results from the presence of absorption sites within the coating or at the coating's interface with the substrate or air. These absorption sites are usually in the form of gross defects that absorb laser energy, resulting in generation of heat that causes localized melting or thermal stress fractures. Failure by this mechanism is usually catastrophic (see Fig. 1).

Noncatastrophic failure, such as plasma burn, is typically the result of unoxidized 1- to 5-μm metallic nodules within the coating. (Some manufacturers will intentionally subject their coated elements to powers sufficient to trigger plasma burns to remove the defect nodules.) Finally, intrinsic material properties determine the laser threshold that an otherwise defect-free film will sustain.

Before deposition

Making high-power laser coatings requires tight control of every aspect of production, from initial substrate manufacture to final packing. Before the substrate even reaches the coating chamber, its surface quality and cleanliness must be assured. A clean coating chamber, appropriate choice of thin-film materials, and good control of process parameters are also essential. After deposition, coating makers must control contamination; even at this stage, surface contamination may cause the element to fail when subjected to high powers. For this reason, meticulous cleaning procedures are also required at the assembly stage, typically under strict clean-room operating conditions.

Substrates for use with high-power laser coatings must be made of high-quality materials. This is particularly important for transmitting optics—these substrates must demonstrate extremely low intrinsic absorption at the relevant wavelengths. Surface defects are potential damage sites and surface quality is specified in terms of a scratch and dig value (the scratch number is given in units of 0.001 mm, the dig number in units of 0.01 mm). High-power laser optics typically specify 20-10 or 10-5 scratch-dig surface values.

The substrates must also be pristine. Any organic or particulate residue from polishing or cleaning may absorb the laser energy and is therefore a potential damage site. For this reason, the substrate and coating interface is a critical area in achieving high damage thresholds. Mirror elements, however, reflect most of the laser energy from the layers closest to the incident media (normally air), and as a result are less sensitive to the presence of defect sites at the substrate surface than transmissive elements.

A clean room helps

Either way, this sensitivity to organic or particulate residue tests the cleaning process. Clean-room conditions help because there is less risk of recontamination after cleaning the substrate. Most coatings companies use lint-free wipes without silicone constituents when cleaning manually in their final clean process. Solvents used are of extremely high purity—typically methanol, isopropanol, or acetone.

Ultrasonic cleaning, when it works efficiently, can be useful and is more effective at dislodging residual polishing compounds than cleaning by hand. Certainly, it is less prone to error.

A typical multistage manual process includes a surfactant wash, several wipes with an ammonia solution, and on the final stage a drag-wipe technique using high-purity solvents. The drag-wipe technique produces very high shear forces, resulting in the removal of any remaining contaminants from the surface.

Contaminants from several parts of a coating chamber can migrate onto the optical surfaces. If the tooling is not scrupulously kept clean, it can contaminate the glass. Backstreaming can occur with an inefficient diffusion pump, resulting in organic contamination.

Finally, the walls of the chamber itself can contribute to contamination of the glass. Material evaporated from a target deposits on both the substrate and on the walls of the chamber. After several runs, the material on the walls builds up until it begins to flake off. During the pump-down sequence, loose particulates can be transferred from the walls of a dirty chamber onto the optic.

The solution is to maintain the cleanliness of the chamber. Many chambers are lined with aluminum foil (made by rolling without oil), while other coaters prefer to use removable steel liners. Cleaning the chamber consists largely of replacing the foil or liners and removing coating buildup from any uncovered areas within the chamber.

Design

For high-power applications, coating designers must choose materials with intrinsically low absorption at the relevant wavelengths, which leaves the designer with only a few material choices in each of the spectral regions. Coatings for use with high-power ultraviolet (UV) light are made of different materials from those for use in the visible and near-infrared (IR). Materials for use in mid- and far-IR coatings are a third group.

Dielectric metal oxides are preferred materials for UV, visible, and near-IR laser applications. Silicon dioxide (SiO2) is the generally accepted and ubiquitous choice for low-index layers. Choosing a material for high-index layers is not as straightforward: oxides of titanium, tantalum, zirconium, hafnium, scandium, and niobium are popular high-index materials.

The design of a coating can significantly alter the damage threshold. In the case of high-reflection coatings, the core structure is typically a repeating stack of high- and low-index layers, each a quarter-wavelength thick. Simply adding a half-wave of low-index material (normally SiO2) as the final layer can result in measurably higher damage thresholds.

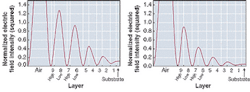

According to some groups, laser-damage thresholds can be increased even further by manipulating the coating layers in at least one of several ways. The electric-field distribution can be averaged across several layers, thereby avoiding a high electric-field concentration within a relatively small number of layers. The high-intensity resonant peaks can be shifted from layer interfaces to locations within the film continuum (see Fig. 2). The highest-intensity resonant peaks can be positioned within the layers of the thin-film material demonstrating the highest damage threshold. Reported results for these techniques, however, are mixed.

Process control

Many parameters play critical roles in the deposition of a high-power laser coating, including the rate of deposition, substrate temperature, oxygen partial pressure (used in designs including dielectric metal oxides), thickness calibration, material-melt preconditioning, and electron-gun sweep. A poorly controlled evaporation process produces spatter from the source, resulting in particulate condensates on the substrate surface and within the depositing coating. These condensates are potential damage defect sites. Unfortunately, some materials that can be used for high-damage-threshold coatings are difficult to deposit smoothly. The settings applied to the electron-gun sweep can be the difference between the production of a clear, high-damage-threshold coating or the production of a high-scatter coating with a much lower power capability.

The rate of deposition, substrate temperature, and oxygen partial pressure (for dielectric oxides) determine the stoichiometry of the growing film, which significantly affects the metal oxide chemistry in the depositing film. These parameters must be optimized and controlled to produce a homogeneous layer with the desired metal-oxygen content and structure.

In producing antireflection coatings, thickness accuracy of the depositing films is an important factor in meeting the desired low reflectance. Mirrors are generally less sensitive to small thickness errors as a result of the relatively broad reflectance band afforded by the refractive-index ratio of the high- and low-index layers. Deep-UV mirrors are an exception, however, because material limitations in this spectral range produce relatively narrowband reflectors.

Ion beams

Ion-beam technology is now a recognized and widely used tool in the manufacture of thin-film coatings, either as an enhancement to thermal evaporation (ion-assisted deposition) or as a sputtering technology (ion-beam sputtering). While these methods produce more compact and durable films with properties closer to those of the bulk materials, conclusive evidence may not exist that ion-beam technology produces higher damage thresholds.

Iain MacMillan is corporate director of coatings at Edmund Industrial Optics, 601 Montgomery Ave., Pennsburg, PA 18073; e-mail: [email protected].