OPTICAL DATA STORAGE:Plastic lenses read data with blue light

TOKYOKonica Corp. has developed a plastic lens for optical pickups that is ideal for the blue-violet-emitting lasers designed for high-capacity 22.5-Gbyte next-generation optical disks. Two 0.85-numerical-aperture aspheric plastic lenses are used for the object lens, with aspheric plastic lenses also used in the aberration correction system.

The object lens weighs about 40 mg. Although it has a two-piece construction, it is shipped as a combined unit, so it can be handled in the same manner as a one-piece lens. The lens is little affected by humidity and temperature changes; even when heated to 30°C, the wave aberration reaches only 0.017 waves root-mean-square (rms) and the magnification remains acceptable. Thus, there is some leeway in adjusting the laser position as it is installed.

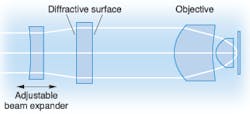

The optical correction system developed jointly with the object lens uses a movable beam expander with two plastic lenses (see figure). It can correct the spherical aberration resulting from the thickness of the protective layer, or from the difference in thickness of the protective layers in two-layer disks. Even if the difference in thickness is about ±20 μm, the rms wavefront error remains below 0.015 wave. In addition, by using a diffractive corrector, color aberrations at the object lens can be removed via achromatization. Such correction also removes focus changes resulting from mode hopping in the laser.

Courtesy O plus E magazine, Tokyo

Encryption

Pattern codes paper images

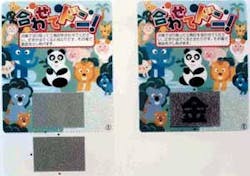

TOKYOToppan Printing Co. Ltd. has developed a new image-coding technology for paper that is an extension of an image-coding technology it developed for plastic cards. The technology involves layering two sand-patterned encoded images to reveal hidden characters and pictures. By combining different coded images, different characters and pictures appear (see figure).

This technology is potentially useful in many consumer-level applications that involve the use of paper-in particular, those related to marketing, advertising, and publishing. For example, it can be used in direct-mail sweepstakes: a customer receiving winning sheets in the mail can go to a participating store and match the sheets with those kept at the store to win a prize. Currently, only black and white images are used, but color may be possible in the future.

This method is an improvement over the method originally designed for hard plastic cards, which has limited applicability since it required using clear plastic sheets. This new method enables the successful decoding of information in spite of distortions and blemishes that can appear in paper, such as moisture damage, wrinkles, and fingerprint smudges. The sheets are also easier to lay on top of each other correctly.

Courtesy O plus E magazine, Tokyo

Air Hockey robot plays optoelectronically

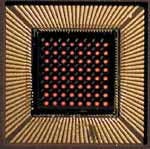

OSAKAThe Advanced Technology Research Laboratories at Matsushita Electric Industrial Co. Ltd. and the Ishikawa Research Laboratory at Tokyo University have jointly developed a high-speed image-processing sensor called "digital smart pixel application" (DSPA) and have made a trial air-hockey robot using this device. The newly developed sensor mounts a light-emitting diode and optical element array with a digital processing element array that has sensing functions and a processor. The image elements are arranged in 8 x 8 or 16 x 16 grids (see figure).

Conventional image sensors typically have only one output port. Even images that are sensed in two dimensions must be converted to serial form before the information can be processed, thus a minimum of 33 ms of processing time is required per image.

In contrast, each DSPA element contains all processing functions: "eyes and ears," "brain," and "mouth." High-speed parallel processing is possible, so each image can be processed in less than 1 ms. In addition, each image element processes the data according to an external processing command, so by changing that external command, many different processing operations can be performed. Also, the output from all of the image elements can be converted at once to an optical signal and sent to another element via an internal flat lens array and polarization array.

The collaboration has created an air-hockey robot built upon a high-speed image-processing system consisting of DSPAs optically linked with optical position-sensitive detectors (PSDs). The robot is able to orient its sensing face toward the direction of the puck and can recognize and track the puck. The puck moves at approximately 10 km/h.

In the robot's vision system, two DSPAs and PSDs have a cascade connection using a stable optical free-space interconnection system that consists of optical elements fused to glass blocks. The cascade-connected DSPAs distribute the work and perform data digitization, center-of-mass calculation, object location and identification processes over multiple steps. This method shortens the time between feedback signals and reduces memory shortage problems.

The line of sight is adjusted every 1.5 ms on the basis of the processed data output. A high-speed rotating scanning mirror is used. The processed data output is simultaneously fed back to the arms of the robot, and the arms move toward the puck to block it. The observation region of the robot is about 20 x 30 cm, but it can locate and identify a fast-traveling puck by adjusting its line of sight.

Courtesy O plus E magazine, Tokyo