PHOTONIC CRYSTALS: Custom-color polymer opals reflect on nature

New flexible polymer opals may offer a new explanation for the origin of the iridescence in butterfly wings, beetles, and natural opals. A multi-institution group led by Jeremy Baumberg at the University of Southampton (Highfield, England) has produced flexible polymer films and moldable plastics with an opalescent sheen that could have numerous colorful applications.1 The potential for high-quality, scalable manufacturing of the artificial opals means they also offer a unique alternative to dyes, which can be toxic and carcinogenic.

While natural opals and photonic crystals are believed to reflect light from an internal lattice structure via Bragg interference, changing color with the angle of reflection, the new manmade opals suggest that iridescence in nature may arise from spectrally resonant scattering rather than reflection. Resonant-scattering events may also explain color features of butterfly wings and iridescent beetles, rather than the usually invoked Bragg-diffraction scheme.

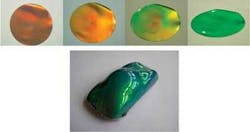

The group used a polymer-melt process to flow and align polystyrene nanospheres coated with a thin layer of polymethylmethacrylate and an outer layer of soft polyethylacrylate (PEA). Application of a shear force caused the particles to self-assemble into a face-centered-cubic lattice, in which the soft PEA shell fills the voids between the spheres. Varying the size of the nanospheres from 200 to 350 nm determines the fundamental optical response of the artificial opals, allowing them to be tuned across the visible and near-infrared parts of the spectrum in such a way that the color is insensitive to viewing angle.

To intensify the color hue, the researchers infused black carbon nanoparticles measuring 50 nm or less throughout the polymer opals. An optimal concentration of 0.05% by weight of the carbon dopant changed the color of the artificial opals from milky white to intense green without disrupting lattice quality (see figure).

The thickness of the malleable material can be well-controlled on an industrial scale to create opal sheets 100 and 300 µm thick, 1 m wide, and 100 m long, which produce highlighted color upon stretching. The opalescent polymer can also be molded and shaped. “This is the first time that large quantities of photonic crystals could be manufactured cheaply,” says Baumberg. “We can now think about using them in simple ways, such as coating mobile phones or as security features for cards or bank notes.” Other applications range from sensing to food packaging.

REFERENCES

1. O. Pursiainen et al., Optics Express 15 (15), 9553 (Jul. 23, 2007).

Valerie Coffey-Rosich | Contributing Editor

Valerie Coffey-Rosich is a freelance science and technology writer and editor and a contributing editor for Laser Focus World; she previously served as an Associate Technical Editor (2000-2003) and a Senior Technical Editor (2007-2008) for Laser Focus World.

Valerie holds a BS in physics from the University of Nevada, Reno, and an MA in astronomy from Boston University. She specializes in editing and writing about optics, photonics, astronomy, and physics in academic, reference, and business-to-business publications. In addition to Laser Focus World, her work has appeared online and in print for clients such as the American Institute of Physics, American Heritage Dictionary, BioPhotonics, Encyclopedia Britannica, EuroPhotonics, the Optical Society of America, Photonics Focus, Photonics Spectra, Sky & Telescope, and many others. She is based in Palm Springs, California.