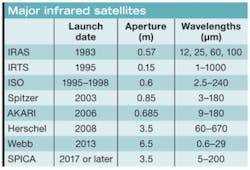

An ambitious new mid- to far-infrared space telescope is in the running for a European Space Agency launch a decade from now. The 3.5 m SPICA (Space Infrared Telescope for Cosmology and Astrophysics) will observe at 5 to 200 µm, filling a crucial spectral gap between two other major infrared observatories now under construction-NASA’s James Webb Space Telescope at shorter wavelengths and the European Space Agency (ESA) Herschel Space Observatory at longer wavelengths (see table). In October ESA selected SPICA and eight other candidate missions for a pair of launch slots in 2017 and 2018 in its Cosmic Vision 2015-2025 program.

Infrared observations promise new insight into crucial astrophysical problems, and the red-shifted distant early universe. Specific targets for SPICA include the birth and evolution of galaxies, the chemical evolution of the universe, and the formation of stars and planetary systems. Atmospheric absorption and the thermal glow of blackbody radiation block ground-based observations in most of the infrared. A series of infrared satellite observatories have made important discoveries, but the largest to reach orbit so far, the Spitzer Space Telescope, has an aperture of only 85 cm.

Like Webb and Herschel, SPICA marks a big step up in aperture and power. The size of earlier infrared (IR) space telescopes had been limited by the need for solid or liquid cryogen to keep the optics and IR detectors cold so their blackbody radiation didn’t overwhelm images of the IR sky. Gradual evaporation of the cryogen limits instrument lifetime. Spitzer was launched with 360 liters of superfluid liquid helium to maintain the instruments at 1.4 K and the telescope itself at 35 K for up to five years after its 2003 launch. With weight at a premium for any satellite, the mass of cryogen and operating lifetime had to be traded off against the size of the optics, limiting Spitzer to a mere 85 cm aperture.

Plans for the SPICA include two stages of mechanical cryocoolers to maintain the primary mirror and instruments at 4.5 K-a two-stage Stirling cooler for precooling to 20 K, and a Joule-Thomson cooler with helium-4 as the working gas to bring temperature down to 4.5 K. A Joule-Thomson cooler using helium-3 will be used to cool the far-IR detectors to 1 K.

Bigger instruments require a different approach to cooling. The generation starting with the 3.5 m Herschel uses other types of cooling systems to reduce the need for cryogen. Herschel needs cryogen to keep its instruments at temperatures from a few tenths of a degree Kelvin to about 8 K, but the telescope optics will be passively cooled to about 80 K. To help maintain that temperature, Herschel will be stationed at the Lagrange 2 point, orbiting about 1.5 million km beyond Earth, after its launch next year. It is expected to operate for at least three years after a six-month commissioning phase that includes placement in its final orbit. Webb will operate at the same location once the 6.5 m telescope is launched in 2013. A shield will block solar radiation from reaching the telescope optics and instruments, passively cooling them to about 45 K. Solid hydrogen coolant will maintain the mid-IR instrument at 7 K for its observations at 5 to 28 µm. After the hydrogen evaporates, observations can continue at shorter wavelengths until Webb runs out of the propellant to keep it at the L2 point (see www.laserfocusworld.com/articles/277182).

Improved sensitivity

Also to be stationed at the L2 point, SPICA promises greater sensitivity than Hershel or Webb between about 10 and 100 µm by maintaining its 3.5 m primary mirror at 4.5 K, according to Takao Nakagawa of the Japan Aerospace Exploration Agency’s Institute of Space and Astronautical Science (Sagamihara, Kanagawa, Japan).1 Cooling the telescope optics increases SPICA’s sensitivity in that mid-IR band by three orders of magnitude, but requires closed-cycle coolers instead of consumable cryogen.

The SPICA team’s design calls for two stages of mechanical cryocoolers to maintain the primary mirror and instruments at 4.5 K-a two-stage Stirling cooler for precooling to 20 K, and a Joule-Thomson cooler with helium-4 as the working gas to bring temperature down to 4.5 K. That cooling is also adequate for mid-IR detectors, but far-IR detectors must be cooled to about 1 K, which requires a separate Joule-Thomson cooler using helium-3 as the working gas. Nakagawa’s group has demonstrated the 1 K cooler in the laboratory; the others have been used or demonstrated elsewhere. Similar coolers are used in ground-based systems.

Lightweight, thermally stable mirrors are another challenge. Webb uses beryllium in its deployable mirror, and Herschel’s mirror is assembled from 12 segments of sintered silicon carbide. The surface tolerance for SPICA’s mirror is an order of magnitude tighter than for the longer-wavelength Herschel, so developers are evaluating performance of carbon-fiber-reinforced silicon carbide as well as sintered silicon carbide. A final decision will come later.

REFERENCE

1. T. Nakagawa and H. Murakami, Advances in Space Research 40, 679 (2007).