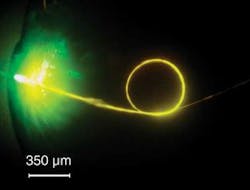

A fiber-ring laser developed by researchers at Zhejiang University (Hangzhou, China) and Fudan University (Shanghai, China) consists of a silica microfiber tied into a knot. In an interesting twist, the active medium is the dye solution in which the fiber is immersed; pumped by 532 nm light from within the solid fiber, the dye solution lases between 570 and 580 nm, evenescently coupling its light back into the microfiber knot.

A central section of a standard single-mode fiber is drawn down to a micrometer-diameter microfiber, and then tied into a knot having a diameter of a few hundred micrometers. Pulsed pump light (6 ns pulse duration) is lens-coupled into the fiber and through the taper into the knot structure. The closeness of the 1.43 refractive index of the solution to the 1.46 index of the fiber ensures a large evenescent field that excites the dye, with a lasing threshold of 9.2 µJ/pulse. Three lasing groups (each of many individual wavelength peaks) centered around 567, 570, and 580 nm were observed. Optimizing the evenescent fields, improving the Q factor, and better resonating the pump and signal light together in the knot. Contact Limin Tong at [email protected].