LIQUID MIRRORS: Metal films may enable revolutionary lunar liquid telescope

Although a telescope on the moon would give astronomers the immense benefit of the pure seeing conditions of a vacuum, getting a telescope there is a massive, expensive undertaking. For the first time, researchers have announced the successful coating of a liquid mirror with a reflective metal that may enable an inexpensive telescope in a low-gravity vacuum like that on the moon.

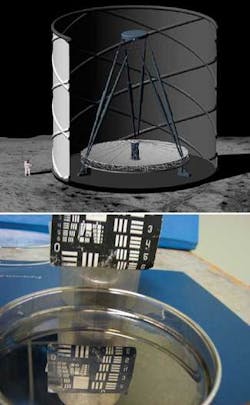

Scientists have previously made the case for a liquid-mirror infrared telescope, or Lunar Liquid Mirror Telescope (LLMT), on the moon with a diameter of 20 to 100 m.1 Such a telescope would enable astronomers to observe objects hundreds of times fainter than the currently proposed next-generation space telescopes (see figure). The infrared part of the spectrum between 0.5 and 5 μm is of particular interest to astronomers because the first stars and galaxies in the universe at redshifts 15 to 20 can be detected there. While a glass-based mirror of that size would be impractical to launch and install on the moon, a liquid-mirror telescope would be inexpensive and conceptually simple to ship and assemble. A liquid mirror retains high optical quality if undisturbed; it also naturally retains a parabolic shape when spun in a gravitational field.

One of the biggest barriers of such a telescope design is that liquid quickly evaporates in the atmospheric vacuum of the moon. The liquid base of the LLMT would need to have high viscoscity, a very low melting point, and virtually no vapor pressure. A multi-institute research team led by Professor Ermanno Borra at the Université Laval (Québec, Canada), first considered several classes of liquids that could be used as the main underlying liquid of the LLMT mirror: highly reflective eutetics of Group 1 metals, low-reflectivity liquids coated with self-assembling nanoparticles, and low-reflectivity liquids coated via sputtering or evaporation with a thin layer of silver.2

Coating ionic material

Coating liquids in a vacuum had never been done successfully before, according to the researchers, so much trial and error was required before they had a breakthrough with low-reflectivity ionic liquids coated with metallic film. Highly viscous ionic liquids are salts composed only of ions, have essentially no vapor pressure, and remain liquid at temperatures below 373 K. In a defining demonstration, the team successfully coated an ionic material called 1-ethyl-3-methylimindazolium ethylsulphate (commercially known as ECOENG 212) with a smooth reflective layer of colloidal silver particles 30 nm thick.

The coating technique used was similar to that used to vacuum-coat optical mirrors, in which a current is run through coating material, causing tiny droplets of (in this case) molten silver to deposit on the liquid. An initial deposition of a 5-nm-thick chromium film before the silver helped improve film reflectivity. In a 1.25 cm2 area, the peak-to-valley deviation was a respectable 0.0373 μm, or a hundredth of a wave at a wavelength of 4 μm. The measurements, which were taken using a Mach-Zehnder interferometer operating at a wavelength of 632.8 nm, were close to the standard deviation of the instrument’s error of measurement.

“The liquid for such a mirror would be flowed in and coated after installation on the moon,” says Borra. “The details on how it will de done and how our coating technique will be adapted to a larger scale will be worked out later. But the most significant outcome of our work is that we showed it is possible to coat a liquid with a reflective layer that does not evaporate.”

The results are promising, not only because of the excellent optical qualities that can be achieved for a cheap liquid mirror, but because ionic liquids offer millions of choices and combinations for optimization of optical characteristics. With the plethora of ionic liquids available for experimentation and the potential for technological improvement, the path to understanding the early universe may be seeing first light.

REFERENCES

1. E. F. Borra, Astrophys. J. 373, 317 (1991).

2. E. F. Borra et al., Nature 447 (7147), 979 (2007).

Valerie Coffey-Rosich | Contributing Editor

Valerie Coffey-Rosich is a freelance science and technology writer and editor and a contributing editor for Laser Focus World; she previously served as an Associate Technical Editor (2000-2003) and a Senior Technical Editor (2007-2008) for Laser Focus World.

Valerie holds a BS in physics from the University of Nevada, Reno, and an MA in astronomy from Boston University. She specializes in editing and writing about optics, photonics, astronomy, and physics in academic, reference, and business-to-business publications. In addition to Laser Focus World, her work has appeared online and in print for clients such as the American Institute of Physics, American Heritage Dictionary, BioPhotonics, Encyclopedia Britannica, EuroPhotonics, the Optical Society of America, Photonics Focus, Photonics Spectra, Sky & Telescope, and many others. She is based in Palm Springs, California.