HOWARD A. SMITH

Infrared (IR) filters are used to help define the wavelength response of IR instruments. Like any good filters, to be effective they need sharply defined spectral shapes with high in-band transmission (or blocking in the case of band-blocking devices) and excellent rejection outside of the bands of interest. Infrared filters play one important role that is often unnecessary for optical filters: they reduce the bright background radiation that can limit the sensitivity of detectors. Hence, cryogenic operation is essential for IR filters to suppress their self-emission, and they must be able to withstand multiple cryogenic cycling without deterioration.

Infrared filters can be made, in rough analogy with optical dielectric filters, by assembling partially reflective layers in quarter-wavelength-spaced dielectric stacks. In practice, however, dielectric stacking is difficult in the IR. The range of indices of refraction in IR-transmitting materials is limited, many of the exotic dielectric materials that are available are hard to work with, and the thick stacks of quarter-wave-spaced dielectrics have problematic stability under conditions of cryogenic cycling or long-term exposure to moisture.

A pioneering alternative for selectively reflecting wavelengths of IR or submillimeter radiation is metal mesh grids made of wires or crosses; the principle is similar to that used for metallic grid reflectors found in microwave oven windows.1 These grids typically come in two geometries: a pattern of narrow, orthogonal wires; and the inverse, a repeating pattern of metal squares supported by a substrate material. Other geometries are also possible, such as cross-shaped structures, dubbed "resonant crosses." The original work used the transmission properties of single grids, but today similar kinds of grids have been successfully stacked together, two or more grids at a time, to make more-refined submillimeter and far-IR filters; they typically have layer spacings of tens of microns or more, and are assembled manually.2, 3 Metallic photonic-band-gap structures—periodic metallic structures that produce frequency regions in which electromagnetic waves cannot propagate—possess some similar mechanical and electromagnetic properties.

Extension to shorter wavelengths

Until now, no one has successfully extended these grid-layering techniques to produce useful shorter-wavelength IR filters. There were three difficult issues to overcome. First, the shorter wavelengths mean that spaces between grid layers have to be smaller while still remaining precise; a cost-effective fabrication method was needed. Next, the grids are most often spaced with a transparent layer of material, but in the IR the absorption of many common materials reduces the transmission unacceptably. Finally, the fabrication steps (including the alignment of geometrical patterns from layer to layer) are expensive; a computational method was needed that could predict the final filter properties with good accuracy.

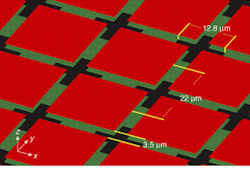

We have made significant progress toward solving all of these problems, and have fabricated IR bandpass filters for use at around 38 µm using a stack of three gold lattice layers spaced by three thin polyimide layers (see Fig. 1). The gold lattices we used in this case have one of two geometries: crosses (holes) in a solid-gold sheet, with cross periodicity of 22 µm and cross-arm lengths of 12.8 µm; and gold squares, which have the same 22-µm periodicity and 18.5-µm-long sides (see Fig. 2). The cross- and square-lattice layers are spaced by 1.2-µm thicknesses of polyimide, resulting in a total filter thickness of about 4 µm. Note that these spacings are very much smaller than the 38-µm resonant wavelength of the filter. Such small spacings have the important benefit of minimizing absorption in the spacer materials (polyimide in this case).Simulation matches measurement

We designed the filter using a standard time-domain electromagnetic-simulation algorithm, the transmission-line-matrix method, which simulated our filters' properties.4 To adapt the method to the problem of IR filters in particular, we used the MicroStripes program and modified it by adding physical parameters that we obtained from iterative comparisons between calculations and measured prototype filters.5 In the end, we obtained good agreement between our predicted transmission profile and the measured one. This confirmation of the accuracy of our code, under these conditions, is significant: it gives us confidence that the many predicted field effects between layers which we are modeling are reliable and accurate, even though the conductive mesh layers in the design are much closer together than the resonance wavelength of the filter. It also gives us confidence that we can tailor the most desirable filter properties by using a variety of alternative geometric design shapes, coupled with a much more complex system of stacked layers.

One of the major advantages of this method of fabricating IR filters is that a simple scaling of the mesh geometries and layer spacings can shift a filter's transmission properties to longer or shorter wavelengths. We have already designed innovative IR filters with other geometries besides crosses and squares—filters with steep cut-ons of greater than 40 dB/µm and narrow bandpass filters with Dl/l of 5%, with good out-of-band blocking.

The filter fabrication was done in the Nanoelectronics Processing Facility at the Naval Research Laboratory (NRL; Washington, DC). We have been working together for more than a decade on the problem of using metal grids in IR applications and have a patent on a technique for making thick metal grids of extremely high quality for use as IR reflectors.6, 7, 8 Our current work builds on these successes. The code was iterated, and the layer-fabrication processes confirmed, with tests on an initial hand-assembled filter made at the Smithsonian Astrophysical Observatory's X-Ray Laboratory. At NRL, we make the filters on a silicon wafer, but remove the film from the silicon in the final step. The process entails laying down a thin-layer polyimide layer, a layer of metal, and then using optical lithography and wet chemical-etching techniques to pattern the metal. We follow with a sequence of polyimide coating, metal evaporation, and optical lithographic pattern definition—in the case of this 38-µm filter, two more iterations were needed to build up a stack of three lattice elements.9 All dimensions were controlled to better than ±0.1 µm, including the alignment between lattice layers.

Tailor-made filters

The most significant results of this work are that the simulations are reliable, the general fabrication techniques are in hand, and the final filters have useful properties. As a consequence, we believe the combination can be used with confidence to tailor-make filters with a wide range of designed properties—narrowband, cut-on, or cut-off filters, beamsplitters, or other devices—without the need for many expensive fabrication trials. Currently, the primary limitation is not set by the fabrication, but rather by the modest absorption in the polyimide substrates, which precludes use for wavelengths below about 20 µm. We have, however, begun investigating alternative processes using films with smaller absorption coefficients. Today we see many possible directions this research (and filter production) might go. Several members of the team are IR astronomers, and indeed astronomy applications were a prime motivator of the development effort (which was supported in part by a NASA grant). But there are other interesting research opportunities and practical uses for this new class of IR optics; we welcome suggestions and inquiries.

Acknowledgments

This research represents the efforts of many people: M. Rebbert of NRL's Nanoelectronics Branch; K. Stewart, O. Sternberg, J. Fischer, R. Bass, and B. Hicks of NRL's Remote Sensing Branch; K. Möller of the New Jersey Institute of Technology; and R. Henry of NASA-Goddard.

The program was supported in part by NASA grant NAG5-7394; O. Sternberg gratefully acknowledges a brief postdoctoral fellowship at Smithsonian Astrophysical Observatory.

REFERENCES

- R. Ulrich, Infrared Physics 7(37; 1967).

- H. Matsuo et al., Pub. Astron. Soc. Japan 42, 3, 459 (1990).

- P. G. J. Irwin et al., Infrared Physics 34(6), 549 (1993).

- W. J.R. Hoefer, IEEE Transactions Microwave Theory and Techniques 40, 1517 (1992).

- MicroStripes Program Version 6, Flomerics Electromagnetics Division, Nottingham, UK (2002).

- J. Taylor et al., Reviews Scien. Instruments 59, 1094 (1988).

- M. Rebbert et al., Applied Optics 33, 1286 (1994).

- C. J. Taylor et al., Method for Fabricating Thin Film Metallic Meshes for Use as Fabry-Perot Interferometer Elements, Filters, and Other Devices, (Navy Case # 70,513, 1987), Naval Research Laboratory, Washington, DC.

- H. A. Smith et al., Appl. Phys. Lett. (May 26, 2003).

Howard A. Smith is a senior astrophysicist at the Optical and Infrared Division, Harvard-Smithsonian Center for Astrophysics, 60 Garden St., Cambridge, MA 02138; e-mail: [email protected].