Because glass is transparent over a wide spectral range, marking glass with laser light is an intriguing challenge. The applied radiation must be efficiently absorbed—for example, by using ultraviolet light. Alternatively, nonlinear absorption can be exploited. Developed a few years ago, glass marking by nonlinear absorption relies on laser pulses of high peak power, which create easily visible microscopic cracks at the focal spot within glass. The benefit is that the focus can be placed below the surface. In this way, three-dimensional marking can be provided in the glass interior by positioning the cracks according to the shape of interest, so that even human figures can be generated in clear glass cubes.

The feasibility of the method depends strongly on the precise deposition of energy within the glass and thus on the laser's focusability (beam quality) and pulse duration. Researchers at the Fraunhofer Institute for Laser Technology and at EdgeWave, a spin-off company of the institute (both in Aachen, Germany), developed a diode-pumped Nd:YVO4 (vanadate) slab laser that is capable not only of marking glass for decorative purposes, but also of becoming a valuable tool in glass cutting even on an industrial scale. In addition, it is a reliable driller of glass and shaper of holes.

The slab design can achieve a high beam quality as well as efficient Q-switching of the stored energy to provide a sufficiently high pulse peak power. Slab-shaped laser media favor (as do disk-shaped media) efficient heat removal as a result of their large surface areas. In this way, thermal lensing can be controlled very favorably. In addition, Nd:YVO4 can produce short pulse lengths at high repetition rates in Q-switched operation due to its high gain cross section and short energy storage time.

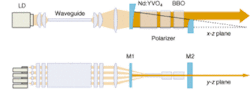

FIGURE 1. A stable/unstable (hybrid) resonator for a diode-pumped Nd:YVO4 slab laser (shown in top and side views) includes a laser-diode (LD) stack and a beta barium borate (BBO) Pockels cell.

In the resonator, the output of a stack of 808-nm-emitting laser-diode bars is shaped by microlenses, prisms, and a beam-folding planar waveguide to a uniform "pumping line" coupled into the Nd:YVO4 slab (see Fig. 1).1, 2 The slab has a neodymium doping concentration of 0.3 atomic percent and measures 1 × 12 (entrance) × 10 (length) mm. As a result of areal cooling and line pumping, a temperature gradient is set up in the y direction so that thermal lensing provides light guiding in that direction along the crystal, keeping the radiation well-collimated in the y-z plane.

Hybrid resonator

A stable resonator design was chosen for the y direction, whereas in the x direction the resonator was made unstable by coupling out 50% of the light. In continuous-wave mode (no Q-switching), the output amounted to 103 W of linearly polarized radiation obtained with 248-W pump power. The beam-quality factor (M2) was less than or equal to 1.5. The polarization was directed along the unstable (x) direction.

For Q-switching, a birefringent polarizer and a beta barium borate electro-optic Pockels cell were introduced into the resonator. In Q-switched operation, 83 W of average power was reached at a pulse-repetition rate of 50 kHz and a pulse length of 11.3 ns. Reducing the repetition rate to 10 kHz, the energy per pulse increased to 5.6 mJ and the pulse duration decreased to 6.45 ns so that the peak power rose to 870 kW. Q-switched operation did not change the beam quality.

The high beam quality allowed for efficient frequency doubling. Using a lithium triborate crystal, a maximum output power of 15.6 W was obtained at a repetition rate of 40 kHz, corresponding to a 60% conversion efficiency.

The high beam quality and peak power opened the door for efficient glass processing.3 Using the fundamental at 1064-nm, a glass sheet of 4-mm thickness was cut by placing a sequence of microcracks and then breaking the glass mechanically. Because of the high repetition rate, a scratching speed of 3 m/s was reached. Curved lines could also be cut, especially by in-depth cutting layer by layer. The roughness of the cutting edges was approximately 10 µm.

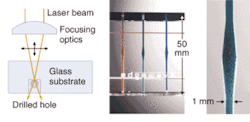

Highly interesting is the ability to drill holes with high aspect ratio or even inner caverns (see Fig. 2). In contrast to "classical" laser drilling, this version of glass drilling is started by focusing the beam through the sheet onto the rear side and then moving the focus across the interior to the front side. In this way, the material is expelled without disturbing the incoming radiation. Glass processing is also possible using the frequency-doubled radiation, allowing finer structures.

REFERENCES

- K. Du et al., Optics Lett. 28(2) 87 (2003).

- H. Zhang et al., Appl. Optics 42(9) 1681 (2003).

- K. Du et al., Glass Sci. Technol. 76(2) 95 (2003).