Varying the emission wavelength of a laser is usually accomplished by tuning the resonator, for example by rotation of a prism or control of the resonator length. Ideally, laser-gain media and wavelength selection would be integrated within one optical element that allows downscaling to microscopic dimensions and integration into optical and optoelectronic circuits. Such an element should contain a broadband gain medium for light stimulation, a frequency selecting device, and the equivalent of an adjustment screw to tune the wavelength.

Researchers at Kent State University (Kent, OH) and Universität Freiburg (Freiburg, Germany) have made strides toward this goal in a novel way. They have developed a laser containing a dye-doped liquid crystalline layer that profits from an intrinsic distributed reflection for optical feedback and is wavelength-tuned by stretching the laser active medium.1

The concept dates back to 1973.2 The mirrorless laser operation is based on the repetitive structure of cholesteric liquid-crystalline phases. Such liquid crystals are helically arranged molecules (chiral nematics) with an orientation that varies linearly along the helix and repeats periodically. As a consequence of the periodicity and the molecular birefringence, the propagation of light of the same helicity in this direction is forbidden for a restricted range of wavelengths; the crystal thus exhibits a photonic bandgap. As a result, the light is strongly reflected.

The edges of the reflection band are at wavelengths equal to the refractive indices (ordinary and extraordinary) multiplied by the period. Doping the liquid crystal with molecules of a dye enables fluorescence. If the homogeneous spectral gain of the dye covers the reflection band and extends past on either side, lasing can occur in narrow spectral bands situated at the reflection band edges. There, reflection changes gradually to transmission so that optical feedback and outcoupling favor the stimulated emission of the energy stored in the gain medium.

The researchers succeeded in producing active laser elastomers in which a helical structure can be modified by external mechanical fields. In a first step, they synthesized a molecular network from four components: a monomer exhibiting a nematic phase, a cholesteric-phase-inducing chiral comonomer, a reactant, and 0.2% weight of DCM (a laser dye). The network showed selective reflection of left-circularly polarized light peaking at 590 nm. Through an anisotropic deswelling procedure, the material was made into a highly ordered macroscopic cholesteric liquid-single-crystal elastomer (LSCE) with oblate chain conformation.

Freestanding LSCE samples were mounted by their four corners and irradiated with 35-ps pump pulses at 532 nm. At lower pump energies, broadband fluorescence was obtained that contracted to a narrow laser line of 0.35-nm width when the pump energy exceeded about 280 mJ. By applying biaxial distortion that compressed the helices and, hence, the pitch, the line could be shifted anywhere within the range 544 to 630 nm (see Fig. 1). The laser emission intensity was limited, however, because heat dissipation reduced the cholesteric order of the low-molar-mass liquid crystals.

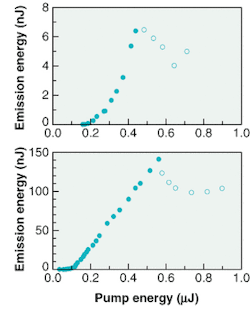

To correct this problem, the Freiburg group compared a crosslinked cholesteric network, in which the cholesteric order is fixated by polymerization by ultraviolet irradiation, to a low-molar-mass monomer liquid crystal.3 The DCM-doped systems were each prepared situated between two glass slides that supported uniform orientation by standard surface-alignment techniques.Again, in both cases, laser lines appeared at the long-wavelength edge of the reflection band, although laser emission at the short-wavelength band was missing because of the mismatch of the dye-transition dipole moment to the electric-field vector (see Fig. 2). A typical threshold behavior is observed in both samples, with a lower threshold in the polymerized sample. More important, the latter shows an energy output higher by more than an order of magnitude, reaching an optical-to-optical efficiency of nearly 30%. Furthermore, the researchers report on much more stable laser emission in case of the polymerized sample, despite minor drawbacks of multiple laser emission due to lack of homogeneity in this first layer. That sample was not tunable by mechanical stretching, however.

Manifold applications of the new device are expected in electro-optics and integrated optics as soon as more details are determined on different excitation methods, frequency ranges provided by different dyes, and methods to technically implement mechanical tuning.

REFERENCES

- H. Finkelmann et al., Adv. Mater. 13, 1069 (2001).

- L. S. Goldberg, J. M. Shnur, US Patent 3 771 065 (1973).

- J. Schmidtke, W. Stille, H. Finkelmann, S. T. Kim, Adv. Mater. 14, 746 (2002).

Uwe Brinkmann | Contributing Editor, Germany

Uwe Brinkmann was Contributing Editor, Germany, for Laser Focus World.