Cylindrical lens boosts amplifier beam quality

Diode-pumped solid-state lasers (DPSSs) based on oscillator-amplifier systems can have better beam quality at medium or high powers than other DPSSs, a quality resulting from the clean beam produced by the oscillator. But the amplifier must be able to take that clean beam and boost its power without degrading its quality. Slab amplifiers provide high powers but often suffer from thermal-lensing problems that reduce beam quality.

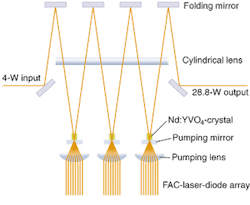

Researchers at Jenoptik (Jena, Germany) are conquering the thermal-lensing problem of slab amplifiers by using a crystal geometry with an elliptical beam cross section combined with cylindrical optics (see Fig. 1). Three small Nd:YVO4 (vanadate) slab crystals of 1-mm thickness are placed close to three laser-diode arrays on a common heat sink. The passively cooled diode arrays are placed on a common heat sink and emit 18 W of light each; lifetime measurements on the laser-diode arrays at the elevated emission power of 40 W show a degradation of less than 2% over a 10,000-h time span. Lenses focus the pump beams into the crystals, producing elliptical foci of 40 µm × 1.8 mm in size. The design permits the crystals as well as the laser-diode arrays to be passively cooled, simplifying the amplifier design.

Light from an external oscillator (a directly end-pumped Nd:YVO4 crystal) is bounced from mirror to mirror in a folded resonator, following a zig-zag path that takes the beam through the three crystals and, repeatedly, through a cylindrical lens that compensates for thermal-lensing distortions. The incoming 4-W beam is amplified to 28.8 W in a process that converts 45.9% of the pump light to amplified light, resulting in a diffraction-limited output beam. Adding a second amplifier stage to the setup has produced a 60-W diffraction-limited beam under laboratory conditions. An acousto-optic Q-switch within the resonator produces pulses that can be varied between 20 and 1000 ns in length, with repetition rates up to 100 kHz.

In one application, a Jenoptik oscillator-amplifier system was used to dice silicon wafers with a cutting speed of 900 mm/s,

a cutting width of 25 µm, and a cutting depth of 80 µm (see Fig. 2). The system produced 700-ns pulses at a 60-kHz rate, with an average power of 24 W reaching the wafer. Other micromachining uses include drilling, surface structuring, and cutting thin foils.