VICTOR I. KOPP, VICTOR M. CHURIKOV, AND AZRIEL Z. GENACK

Transmission through optical fibers is sensitive to a wide range of factors including stretching, compression, axial twist, and temperature of the fiber, as well as the refractive index of the surrounding medium. This sensitivity can be exploited to create fiber-optic sensors that imprint information about these factors upon the light passing through the fiber. Precise periodic modulation of fiber structures produces sharp spectral features in the reflection or transmission spectrum of the fiber. Changes in the spectra can therefore describe variations in strain, axial twist, liquid level, pressure, and temperature.

Chiral fiber gratings, in which a periodic structure is created via a helical variation along the fiber axis of birefringence perpendicular to the axis, are used in a variety of applications. Such fibers differ from traditional fiber Bragg gratings (FBGs), in which the periodic structure is created via a variation in the index of refraction along the fiber axis.

Traditionally, periodic structures are fabricated by exposing the fiber to a periodic pattern of ultraviolet light that produces a modulation of the index of refraction along the length of a photosensitive fiber.1 When the period of modulation of the fiber structure is as short as half the optical wavelength, the light within the core is evanescent within the structure over a band of wavelengths and is thus strongly reflected. The central vacuum wavelength of the reflection band in such FBGs is equal to the product of the structure and the effective refractive index of the core mode. If the period greatly exceeds the optical wavelength, core and cladding modes can still be coupled via the grating to produce several narrow dips in the transmission spectrum. In this case, in addition to sensitivity to temperature and elongation, the spectral position of the dip is sensitive to the refractive index of the surrounding medium, which affects the propagation constant of the cladding modes.

Chiral optical fibers

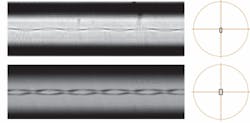

Chiral optical fibers are produced by twisting fibers as they pass through a miniature oven to create a periodic structure. Twisting concentric birefringent fiber preforms or nonconcentric fibers, respectively, produces stable structures with double- or single-helix symmetry (see Fig. 1). While double-helix structures are polarization sensitive, single-helix structures are insensitive to the incident polarization, enabling fabrication of gratings. These fibers are useful as sensors, in-fiber polarizers, lasers, and filters.3, 4, 5 Twisting uniformly heated standard single-mode fiber with residual nonconcentricity also produces long-period helical fiber gratings.6

Twisting birefringent fiber with concentric noncircular cores with 180° rotation symmetry creates double-helix structures. The period then equals one half the turn, so that the pitch, P, is twice the period, a, or P = 2a. Narrow dips arise in the transmission spectrum when light is resonantly coupled between the core and cladding in chiral long-period gratings (CLPGs) with a pitch much greater than the wavelength. In chiral gratings with a pitch slightly shorter than in CLPGs, the wave couples to free space and escapes the fiber. This scattering occurs at the edge of the scattering band, and is polarization selective. These chiral intermediate-period gratings (CIPGs) are the basis of linear and circular polarizers with bandwidths of over 100 nm. Twisting fiber with a nonconcentric core produces a periodicity in the refractive index equal to the pitch, P = a, which creates single-helix structures. The periodic helical modulation of the fiber core is similar to modulation in fiber long-period gratings produced by microbending.

Chiral-fiber sensors

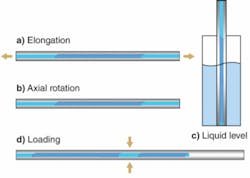

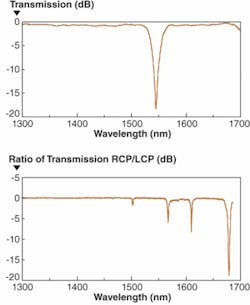

We have developed and demonstrated single- and double-helix chiral gratings that have application as sensors of liquid level, temperature, elongation, axial twist, and pressure (see Fig. 2). The single-helix CLPG is formed by twisting a fiber with an eccentric core displaced approximately 2 µm from the center of the fiber. The major and minor axes of the core are 6 and 3 µm, respectively. Indices of the core and cladding are 1.48 and 1.45, respectively. The transmission spectrum of the single-helix CLPG with a pitch of 517 µm is essentially independent of input polarization (see Fig. 3, top). Chiral gratings can be interrogated either in transmission or in reflection if a micromirror is attached to the CLPG.

To create a strain sensor, we elongate a single-helix CLPG over the range of 500 to 2500 microstrain. The elongation results in a shift of the spectral dip with a coefficient of -3.5 × 10-4 nm/microstrain. We also demonstrated the use of the single-helix CLPG as a torque sensor responding to axial twisting. The shift coefficient of the characteristic dip in transmission is 72 nm/(rev/cm).

To fabricate the double-helix CLPG, we created a high-index rectangular core with an aspect ratio of 2:1 using low-temperature glasses. The indices of refraction of the core and cladding were 1.7 and 1.5, respectively. The birefringence of the fiber corresponded to a value of the effective-index modulation that is larger than ever has been achieved with photosensitive glasses. Such high-index modulation results in stronger coupling and allows for shorter devices. In the transmission spectrum of a 55-mm-long double-helix CLPG with pitch of 78 µm, the polarization selectivity is clear from the ratio of co-handed to cross-handed transmission. The dips exist only for a co-handed wave. The light wave is co-handed when it has the same handedness as a structure and cross-handed for opposite handedness. (see Fig. 3, bottom).

A liquid-level sensor was demonstrated by vertically inserting the CLPG into a container filled with alcohol. The optical transmission at wavelengths at the side of the transmission dip is affected by the liquid level since the dip shifts with a coefficient of 35 pm/mm of liquid level over a range of 0 to 35 mm.

The use of microforming in CLPGs, as opposed to photo-induced index change, enhances the long-term stability of the gratings, making them more suitable for applications in harsh environments.

Microformed CLPGs are also used as high-temperature sensors. We followed the change in the wavelength of the CLPG dip produced by the coupling of the core mode to the fourth cladding-mode dip in a single-helix CLPG changed with temperature in real time. Excellent stability and temperature sensitivity were found up to 400°C. The sensitivity near 400°C is 0.11 nm/°C.

Both single- and double-helix-based CLPGs can be used in pressure sensors to measure pressure via strain or torque measurements, using an appropriate transducer. Several characteristics of in-fiber polarizers based on double-helix CIPGs are advantageous for applications to pressure sensing. These characteristics include the scattering of unwanted polarization out of the fiber—as opposed to absorption of the rejected radiation in conventional polarizers—and their flexibility and light weight. The scattering of light with unwanted optical polarization allows the use of a high-peak-power laser for interrogation, while the flexibility of the polarizers facilitates their integration into the delivery fiber. Two crossed chiral polarizers connected by a portion of polarization-maintaining (PM) fiber prevent any light from passing through. When pressure is applied to the PM fiber, optical polarization is no longer strictly maintained so the transmission through the crossed polarizers increases. Such measurements of pressure have a dynamic range of nearly 40 dB over a load range from 5 to 1000 grams.

We have also demonstrated fuel-level sensors with both single- and double-helix chiral-fiber gratings.

Experiments have demonstrated that chiral-fiber gratings produced by twisting optical fibers are robust fiber sensors with high dynamic range. Lifting the restriction that the cores be photosensitive allows the use of glass combinations that can withstand harsh environments and high temperatures. In addition, it allows the fabrication of in-fiber devices using unconventional glasses such as ZBLAN or chalcogenides for the mid- and far-infrared spectral ranges. The stronger modulation of the effective refractive index allows for more compact devices. Polarization-sensitive double-helix CLPGs allows an effective doubling of the number of sensing channels by using polarization multiplexing. The additional channels also can be used to test the integrity of the sensor network. The flexibility offered by chiral fibers broadens design choices for sensors for a wide range of applications.

Acknowledgments

This work was supported by the U.S. Department of Commerce, National Institute of Standards and Technology, Advanced Technology Program, Cooperative Agreement 70NANB3H3038, and the National Science Foundation under Grants DMI-0340149 and DMI-0450551.

REFERENCES

1. A. Othonos and K. Kalli, Fiber Bragg gratings: fundamentals and applications in telecommunications and sensing, Artech House, Norwood, MA (1999).

2. V. Kopp et al., Science 305, 74 (2004).

3. V. Kopp et al., J. Opt. Soc. Am. B 24, A48 (2007).

4. V. Kopp et al., Opt. Lett. 31, 571 (2006).

5. V. Kopp and A. Genack, Opt. Lett. 28, 1876 (2003).

6. O. Ivanov, Opt. Lett. 30, 3290 (2005).

7. P. Cielo and J. Lapierre, Appl. Opt. 21(4) 572 (1982).

Victor I. Kopp is the director of research and development, Victor M. Churikov is a senior scientist, and Azriel Z. Genack is the chief technology officer at Chiral Photonics, 26 Chapin Road, Unit 1104, Pine Brook, NJ 07058; Genack is also Distinguished Professor of Physics at Queens College of the City University of New York, Flushing, NY 11367; e-mail: [email protected]; www.chiralphotonics.com.