MAARTEN NIESTEN, MIKE SCHAAF, AND DAVID LASHMET

The cell-phone revolution is rapidly becoming a visual revolution, too. From quartz displays in the first handsets to color touch screens, the entire surface of a cell phone has potential as an information display. But the physical limits to this pocket-size display hold back advances in camera chips, mobile TV resolution, and cellular network speed. Tiny projectors inside cell phones can break this bottleneck by using color lasers that are modulated at nanosecond rates.

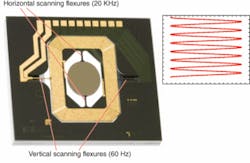

Light sources and the means to array pixels in order are required to recreate any digital image. Intriguingly, for very small projectors, lasers are integral to this process. Rather than illuminating a grid of light valves or mirrors, like most projectors do, the smallest projectors use a single mirror that can rotate biaxially. This one mirror can raster-scan a 2-D image, rather like a cathode-ray tube does. But instead of a beam of electrons, this scanning mirror projector uses a beam of photons—much like a television set without the glass or the phosphors (see Fig. 1).

In essence, this scanning mirror creates an image, pixel by pixel, by modulating the lasers. This 2-D microelectromechanical systems (MEMS) mirror is metal on silicon, specifically designed to naturally resonate at a particular frequency so that one axis of rotation scans very quickly. The other axis of rotation is driven slowly. Together, they bob and weave to scan images at video rates. The latest version of our MEMS mirror projection system produces wide WVGA resolution (854 × 480 pixels), and higher resolutions may be possible.

Killer apps

Cellular telephones are only one possible application of this projection technology. Given its small size, minimal power requirements, high contrast, and inherent brightness, these projectors have potential in automotive applications, such as full-color head-up displays (HUDs). Lasers provide enough luminance to overcome daylight conditions and can be powered down to zero. This eliminates contrast issues for nighttime driving—in liquid-crystal-display HUD systems the backlight can leach through the liquid crystals to reduce night vision. The tiny projector technology involves just eight bits of color per channel where pixels are needed, and no bits of color where they are not. Additionally, the lasers in the system have much higher dynamic range, which allows them to be very dim at night and very bright in daylight.

This MEMS-based laser projector is also potentially an eyewear-display solution, in which the laser light from the projector passes before a transparent ocular. Military, medical, industrial, or even consumer applications with this sort of augmented vision are possible. This same projector can accompany personal media players, such as MP3 players or laptop computers. Given its small footprint, low power, and high resolution, however, the broadest application for this projector technology is in cellular handsets. This would follow the convergent trend of visual devices like digital cameras, video recorders, and color LCD panels, although in this case, the projector increases the functionality of the other three.

Using lasers as light sources is particularly valuable in projectors. The Helmholtz-Kohlrausch effect causes saturated colors in very narrow wavelengths to be perceived as up to 50% brighter than broader wavelengths of colored light, such as those produced by light-emitting diodes. Thus, the observed image has a significant increase in brightness without additional battery power. Besides the H-K effect, lasers also provide nearly infinite focus. So users need not adjust any guiding optics to display an image. The image remains focused even across curved surfaces or corners, which auto-focusing capabilities can not measure. In short, many novel mobility applications are enabled by lasers, as long as these light sources can be modulated rapidly.

It is important to note that this scanned laser approach does not produce color break-up if the user moves the projector while holding it, because the colors of each pixel are created simultaneously. In fact, given the 60 Hz frame-refresh rate of this scanning laser system, if a user moved the projector 60° in one second, the frame would only tilt by 1°, which the eye cannot recognize. In contrast, in projection systems that use an array of sequentially illuminated pixels, moving the projector only 6° per second degrades image quality. In such projectors, even a 240 Hz frame-refresh rate per color channel causes the channel-specific picture elements to improperly overlap on the display surface. This color-break-up effect is commonly called a “rainbow effect.” Technically speaking, the use of ultrafast laser diodes with their broad color palette and a two-dimensional MEMS mirror with no fixed screen eliminates smeared “rainbows.” In fact, this resistance to motion artifacts also enables image stabilization.

Modulating green

In 2003, the “Nomad” monochrome red retinal-scanning display demonstrated 10-ns-per-pixel modulation. Thanks to Shuji Nakamura, blue laser diodes are now commercially available, some of which are also easy to modulate at 10 ns per pixel. The difficulty comes with the green laser, which is not a single diode. Instead, it is an infrared (IR) diode laser whose light passes through a frequency doubler—typically a periodically poled lithium niobate (PPLN) crystal. Doubling the frequency halves the wavelength, which is how a 1060 nm infrared light source produces 530 nm (green). Unfortunately, this is a nonlinear process with low conversion efficiency. But human observers are much more sensitive to green than the other primary colors, so a little green goes a long way.

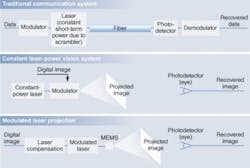

The challenge is with modulation. The IR laser requires a relatively high current to generate green light. As a result, the temperature of the green laser can increase substantially. The lasing wavelength of the infrared laser will change as a function of temperature and will move away from the wavelength accepted by the frequency doubling crystal. When this happens, the amount of green light generated is drastically reduced. Furthermore, the heat causes a change in the effective cavity length of the infrared laser such that the laser wants to hop to a different mode at a slightly different wavelength. Such a different mode can be lower in intensity, which reduces the output of green (see Fig. 2).In telecommunications, mode hopping is minimized by modulation of the laser at high frequency from an “off” state to an “on” state. This high modulation frequency tends to keep the laser temperature stable, and it adds receiver variable gain that means reception is always correct digitally. In large laser-based displays, like rear-projection TVs, the IR-to-green laser is driven at a constant power, with modulation happening in a light valve, such as a large array of small moving mirrors. This constant laser power means little risk of mode hopping. In the case of directly modulated lasers, all power at modulated values must be stable to ensure a color-balanced image. Human observers with our “biological photodetectors” do not correct for intensity distortion. The laser light output must be predicable at any given desired intensity. One approach to stabilize the laser is to rigorously control the temperature the frequency doubler and lock in the wavelength with a narrow band filter.

Picoprojectors

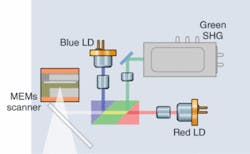

This level of thermal control can allow ultrafast modulation of the green laser diodes, yielding eight bits of green. Combined with red and blue diodes, these three laser beams reflect off a biaxially oscillating MEMS mirror, which allows raster scanning of digital images to produce a bright, high-resolution video frame—one that is motion insensitive and precisely focused all the time. If the total system is fast enough to construct at least 30 frames per second, video images are possible. The PicoP projection system is capable of 60 frames per second of WVGA resolution video, which fits and functions inside a working cellular telephone. The near-term goal is to integrate all of the necessary optics, MEMS, laser light sources, and electronics into a single 7 cc package for use in consumer cell phones in the coming years (see Fig. 3).As laser technology develops, even more revolutionary technologies will follow. Even minor improvements in laser-diode electrical-to-luminance efficiency affect the battery life of small electronic devices. A tiny laser projector encased in a handheld mobile device can create exciting new display capabilities for consumers. In the not too distant future, further advances of green-laser technology may lead to commercially encasing a tiny laser projector directly into the frames of eyeglasses that would enable viewing of personal navigational cues in full color with sufficient brightness for outdoor viewing. In five years, we predict that you won’t need to look down at a small handheld display screen to view information when you walk or drive. Boundless mobility comes from a tiny MEMS mirror, and laser diodes in red and blue and green.

MAARTEN NIESTEN is optics/photonics engineering manager, MIKE SCHAAF is senior staff engineer, and DAVID LASHMET is market analyst at Microvision, 6222 185th Ave. NE, Redmond WA, 98052; e-mail: [email protected]; www.microvision.com.